Abnormal detection method of machine tool spindle

An anomaly detection, machine tool spindle technology, applied in measurement/indication equipment, metal processing mechanical parts, metal processing equipment, etc., can solve problems such as limited application scenarios, improve real-time performance, save data communication bandwidth and server computing resources , the effect of improving the robustness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

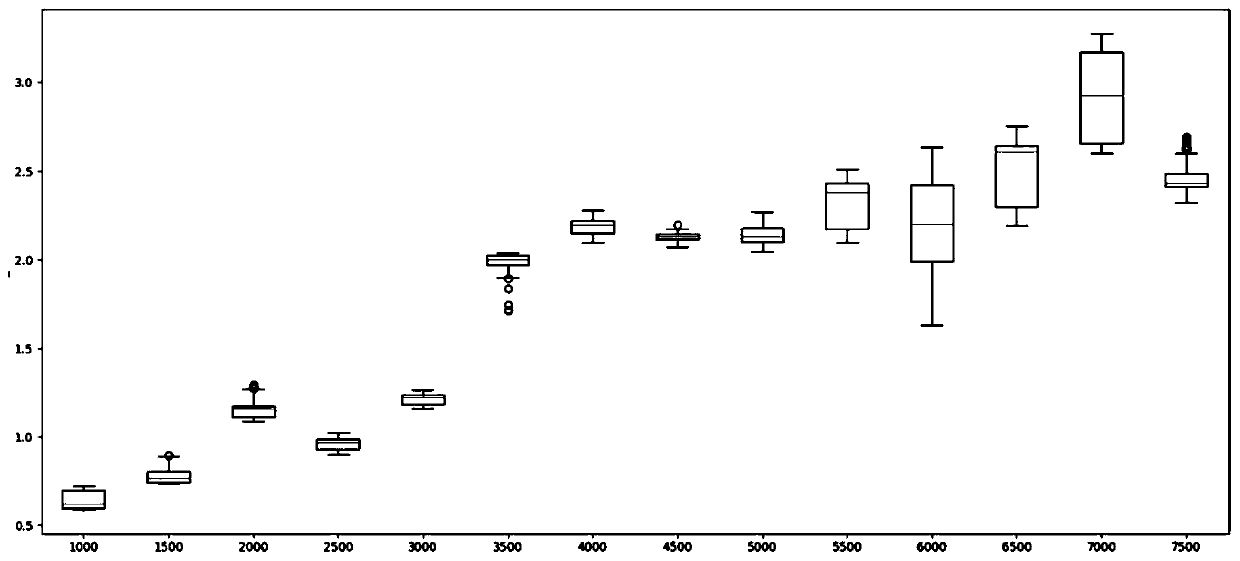

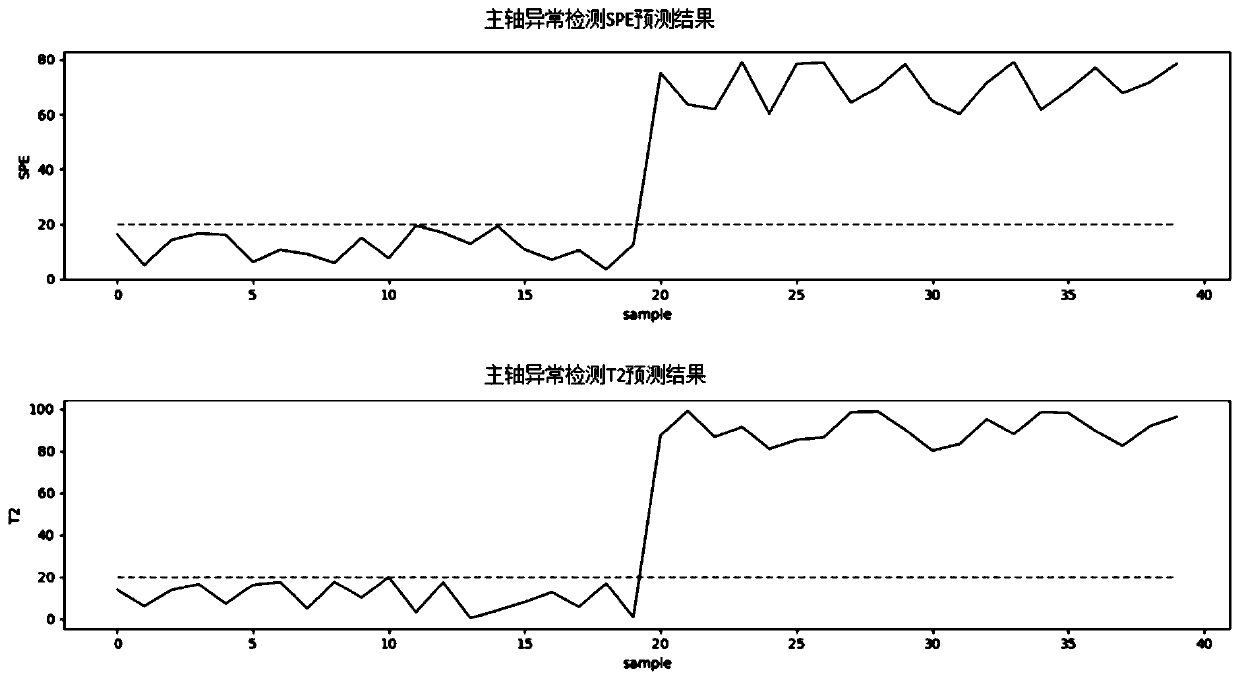

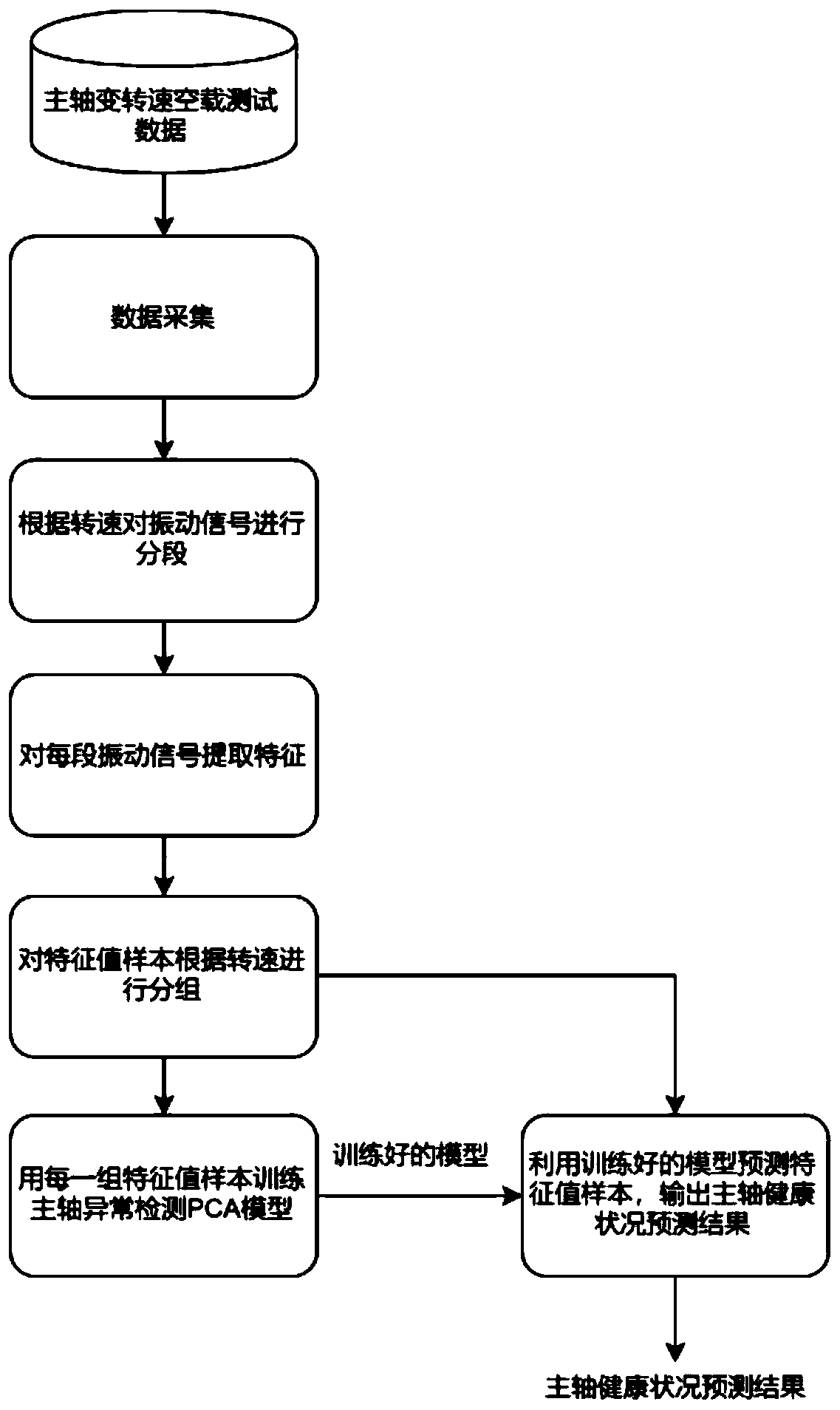

[0052] In order to more intuitively describe the abnormality detection method of the machine tool spindle based on edge computing and variable speed no-load test of the present application, a specific embodiment is given below. The equipment used in this embodiment includes a CNC machine tool (numerical control machine tool), a three-axis vibration acceleration sensor, a high-performance edge embedded device with three high-speed analog-to-digital (ADC) acquisition channels, and a server. Specific steps are as follows:

[0053] (1) Install a vibration sensor at the end of the CNC machine tool spindle shell near the tool handle to measure the vibration signal when the spindle rotates. The sensitivity of the vibration sensor can be, for example, 5 mV / g, and the frequency measurement range is 2-8000 Hz.

[0054] (2) The output signal of the vibration sensor is connected to the three ADC acquisition channels of the edge embedded device. The sampling rate of the ADC is 25.6kHz and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com