Anti-corrosion and anti-radiation method for steel plate

An anti-corrosion and anti-radiation technology, applied in chemical instruments and methods, layered products, lamination devices, etc., can solve the problems of component deformation, anti-corrosion effect and poor service life, and achieve uniform and strong bonding and long service life. , The effect of simple and controllable processing technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

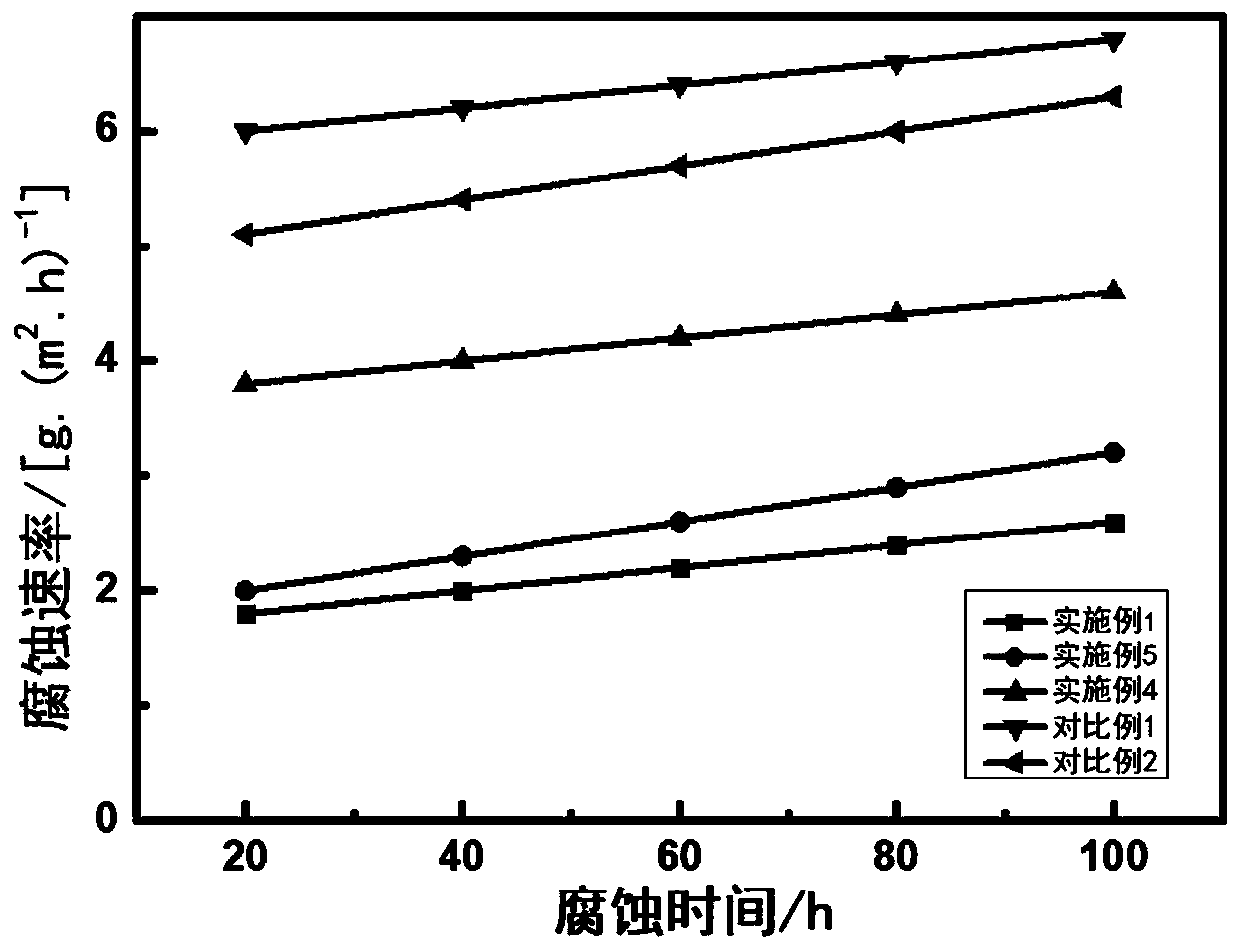

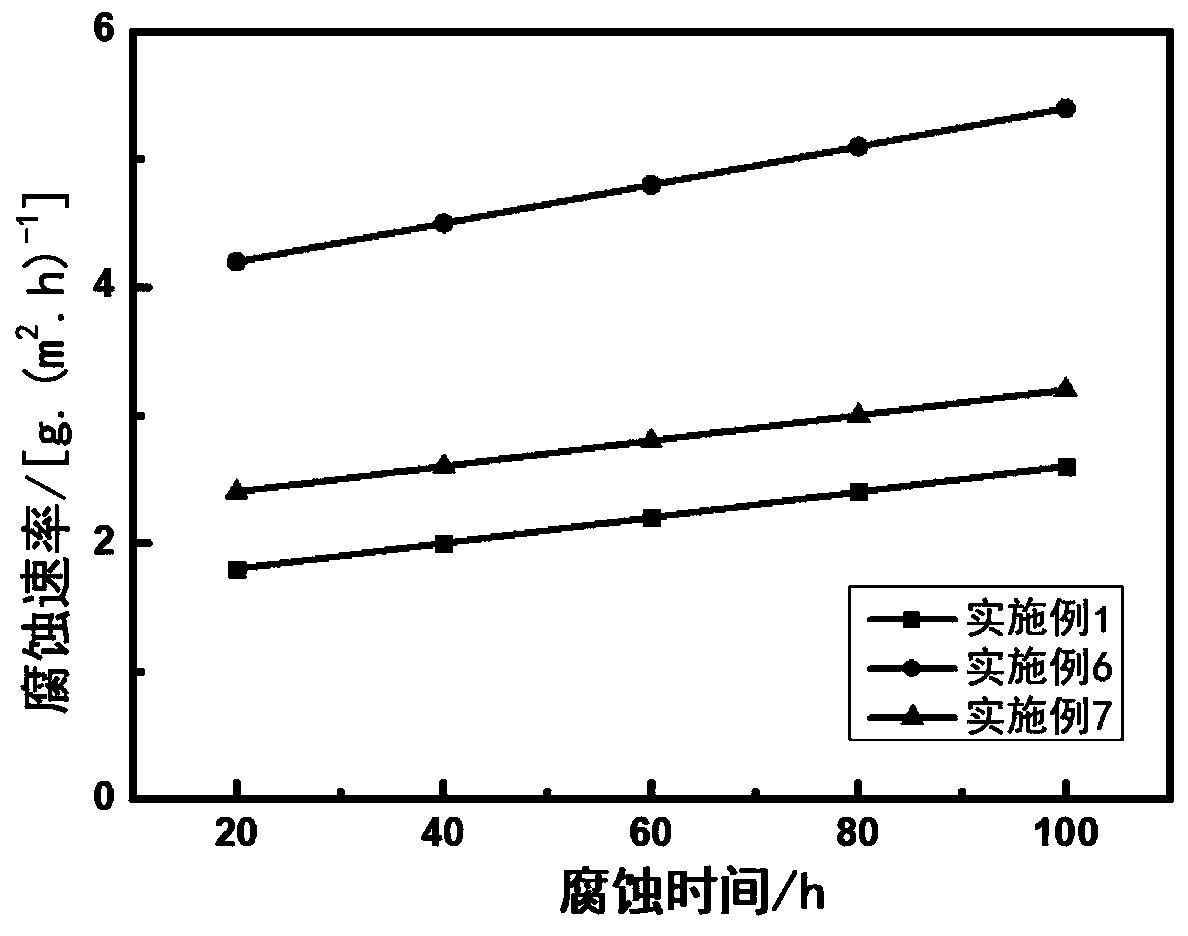

Embodiment 1

[0030] This embodiment provides a steel plate anti-corrosion radiation protection method, comprising the following steps:

[0031] S1. Use an electrostatic precipitator to remove dust from the surface of the hot-rolled steel plate;

[0032] S2, pre-treatment of metal cladding film;

[0033] S3. Transport the hot-rolled steel plate with a temperature of 1000°C and the metal brass clad film with a thickness of 1mm to between the upper and lower rolls of the lamination equipment;

[0034] S4. Hot cladding: Metal brass cladding film and hot-rolled steel plate are softened under the pressure of the upper and lower rolls and the high temperature of the hot-rolled steel plate, and then melted together with the hot-rolled steel plate to obtain rolled steel coated with metal film plate, the pressure between the upper and lower rollers is controlled at 70kg / cm 2 ;

[0035] S5, film quality monitoring;

[0036] S6. Cutting and forming: After the rolled steel plate covered with metal ...

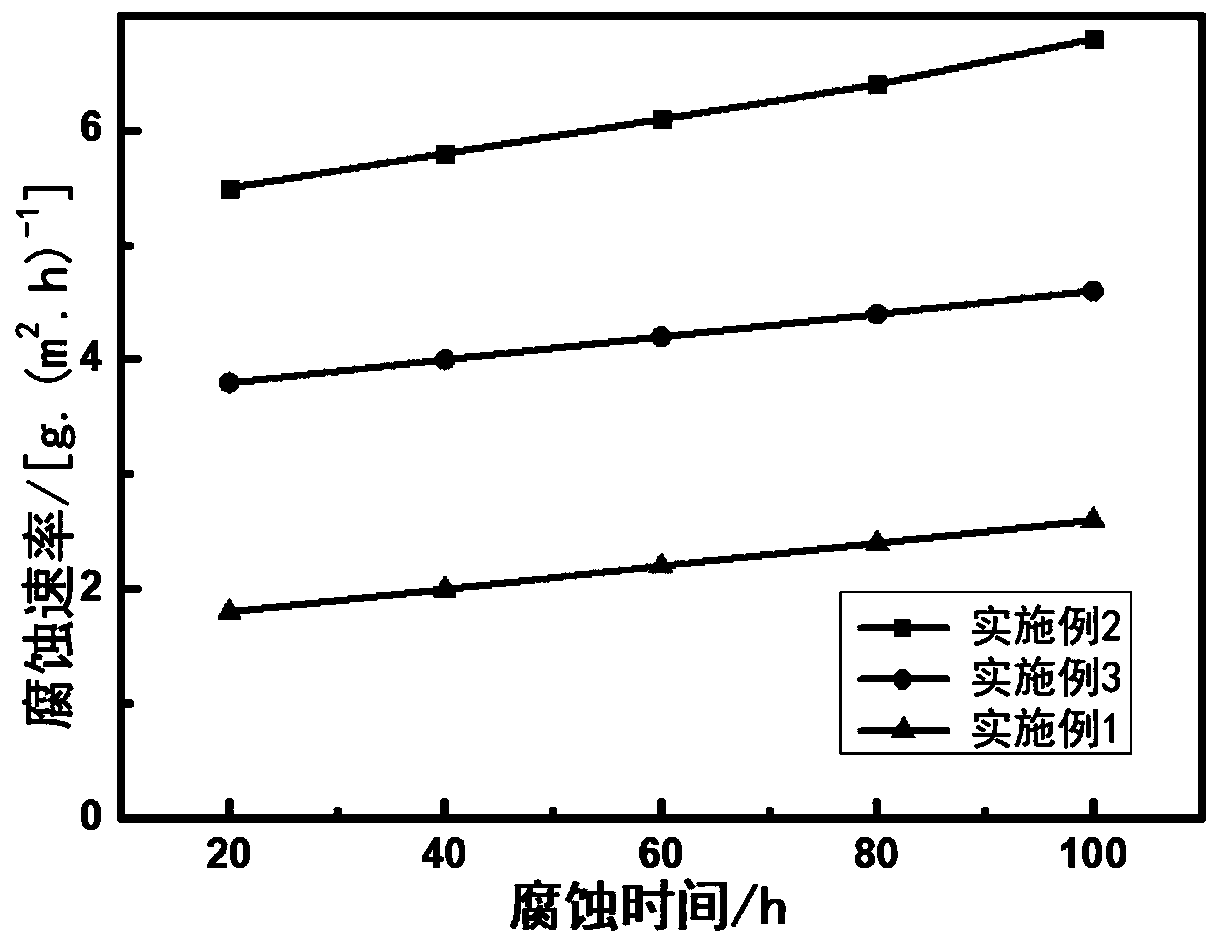

Embodiment 2

[0038] This embodiment provides a steel plate anti-corrosion radiation protection method, comprising the following steps:

[0039] S1. Use an electrostatic precipitator to remove dust from the surface of the hot-rolled steel plate;

[0040] S2. Pretreatment of metal aluminum laminated film;

[0041] S3. Transport the hot-rolled steel plate with a temperature of 1000°C and the metal aluminum clad film with a thickness of 1mm to between the upper and lower rollers of the lamination equipment;

[0042] S4. Hot cladding: the metal aluminum cladding film and the hot-rolled steel plate are softened under the pressure of the upper and lower rolls and the high temperature of the hot-rolled steel plate and melted together with the hot-rolled steel plate to obtain a metal-aluminum film. Rolled steel plate, the pressure between the upper and lower rolls is controlled at 70kg / cm 2 ;

[0043] S5, film quality monitoring;

[0044] S6. Cutting and forming: After the rolled steel plate co...

Embodiment 3

[0046] This embodiment provides a steel plate anti-corrosion radiation protection method, comprising the following steps:

[0047] S1. Use an electrostatic precipitator to remove dust from the surface of the hot-rolled steel plate;

[0048] S2. Pre-treatment of metal titanium lamination film;

[0049] S3. Transport the hot-rolled steel plate with a temperature of 1000°C and the metal titanium clad film with a thickness of 1mm to between the upper and lower rollers of the lamination equipment;

[0050] S4. Thermal cladding: The metal titanium cladding film and the hot-rolled steel plate are softened under the pressure of the upper and lower rolls and the high temperature of the hot-rolled steel plate and melted together with the hot-rolled steel plate to obtain a metal titanium film. Rolled steel plate, the pressure between the upper and lower rolls is controlled at 70kg / cm 2 ;

[0051] S5, film quality monitoring;

[0052] S6. Cutting and forming: After the rolled steel pl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com