Preparation method of self-supporting and self-repairing host-guest film

A self-healing, host-guest technology, applied in the field of self-supporting self-healing host-guest film preparation, can solve unreported problems, and achieve the effect of simple operation and short time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

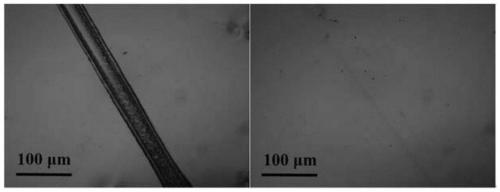

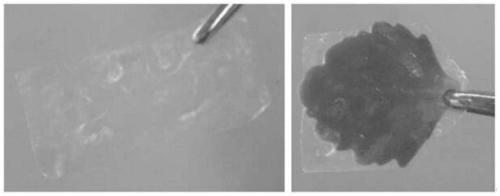

[0022] A method for preparing a self-supporting self-repairing host-guest film, using layer-by-layer self-assembly technology to assemble β-cyclodextrin-modified silk fibroin and adamantane-modified hyaluronic acid onto the substrate surface, and using ethanol treatment to obtain self-supporting self- Repair host-guest film.

[0023] Including the following steps:

[0024] 1. Using EDC / NHS as a cross-linking agent, graft β-cyclodextrin on silk fibroin, and graft adamantane on hyaluronic acid to form β-cyclodextrin-silk fibroin and adamantane-hyaluronic acid solution;

[0025] 2. Using the brushing method in the layer-by-layer self-assembly technology, first brush a layer of β-cyclodextrin-silk fibroin on the surface of the glass sheet, dry at room temperature, and then brush a layer of adamantane-hyaluronic acid to dry, repeat 15-30 cycles of the above steps;

[0026] 3. After soaking in absolute ethanol for 24-48 hours, the film can be peeled off from the glass slide, and ...

Embodiment 1

[0029] 127mg EDC and 76mg NHS were formulated as EDC / NHS mixed solution.

[0030] Put 750mg of β-cyclodextrin and 320mg of silk fibroin together in the EDC / NHS mixed solution and activate at room temperature for 12 hours to obtain 8 mg / mL of β-cyclodextrin-silk fibroin solution.

[0031] 100 mg of adamantane and 160 mg of hyaluronic acid were placed in the EDC / NHS mixed solution and activated at room temperature for 12 hours to obtain a 4 mg / mL adamantane-hyaluronic acid solution.

[0032] Using the brushing method in the layer-by-layer self-assembly technology, first brush a layer of β-cyclodextrin-silk fibroin on the surface of the glass sheet with a brush, dry at room temperature, and then brush a layer of adamantane-hyaluronic acid to dry, repeat The above steps are 30 cycles.

[0033] Soak the prepared film in absolute ethanol for 24 hours, the film can be peeled off from the glass slide, and can be attached again after wetting other substrates.

Embodiment 2

[0035] 190mg EDC and 114mg NHS were formulated as EDC / NHS mixed solution.

[0036] 1477 mg β-cyclodextrin and 340 mg silk fibroin were placed in the EDC / NHS mixed solution and activated at room temperature for 16 hours to obtain 8.5 mg / mL β-cyclodextrin-silk fibroin solution.

[0037] 150 mg of adamantane and 200 mg of hyaluronic acid were placed in the EDC / NHS mixed solution and activated at room temperature for 16 hours to obtain a 5 mg / mL adamantane-hyaluronic acid solution.

[0038] Using the brushing method in the layer-by-layer self-assembly technology, first brush a layer of β-cyclodextrin-silk fibroin on the surface of the glass sheet with a brush, dry at room temperature, and then brush a layer of adamantane-hyaluronic acid to dry, repeat The above steps are 25 cycles.

[0039] Soak the prepared film in absolute ethanol for 32 hours, the film can be peeled off from the glass slide, and can be attached again after wetting other substrates.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com