Reactive dye containing iso-dication groups as well as preparation method and application of reactive dye

A dicationic, reactive dye technology, applied in reactive dyes, dyeing methods, azo dyes, etc., can solve the problem of low dyeing fixation rate, reduce environmental pollution, excellent color fastness, good color fastness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

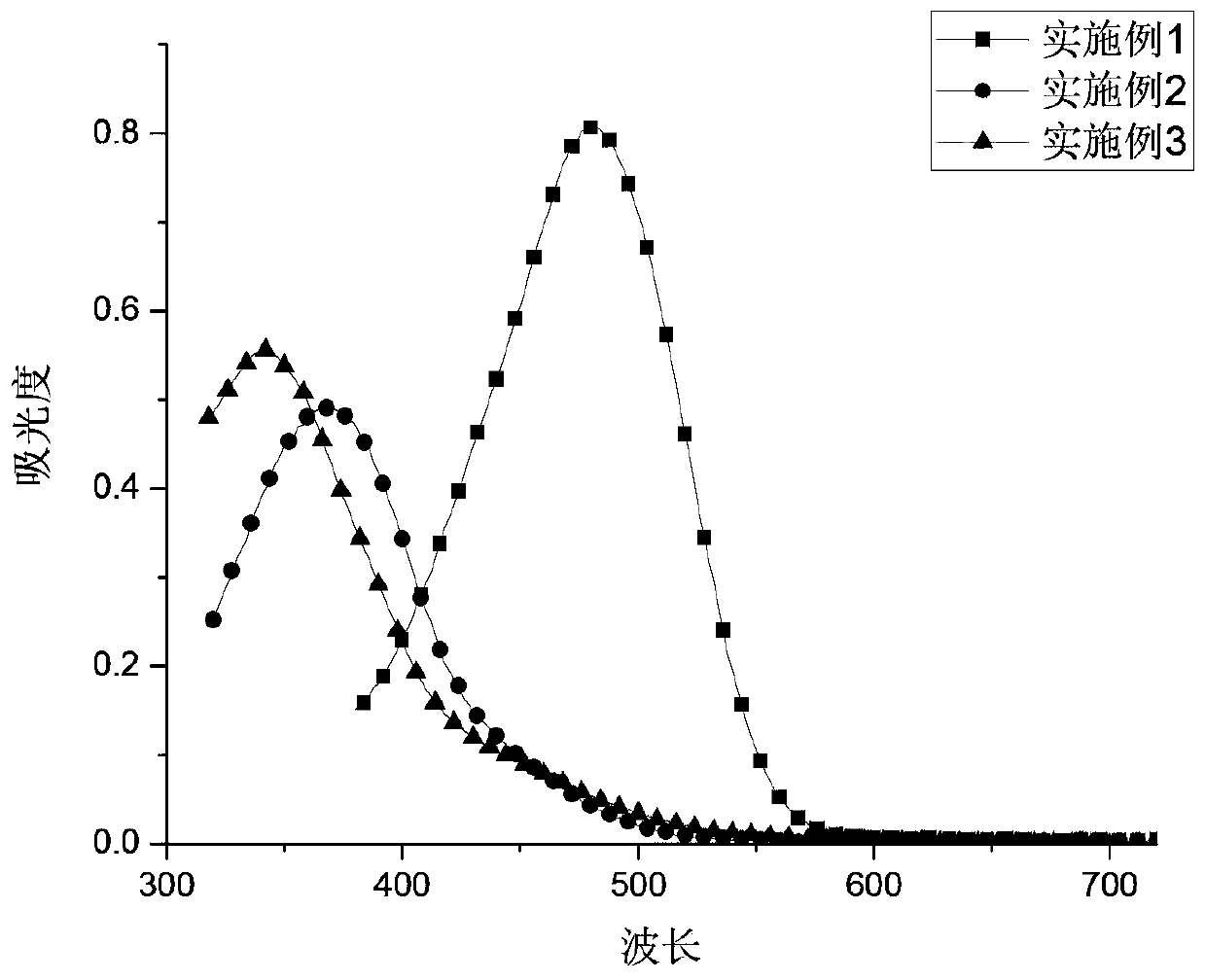

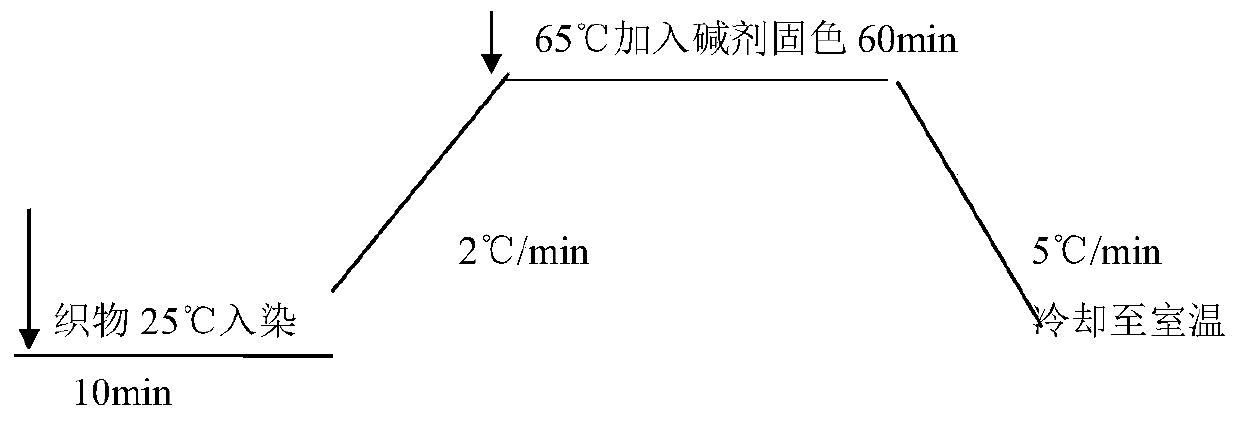

Embodiment 1

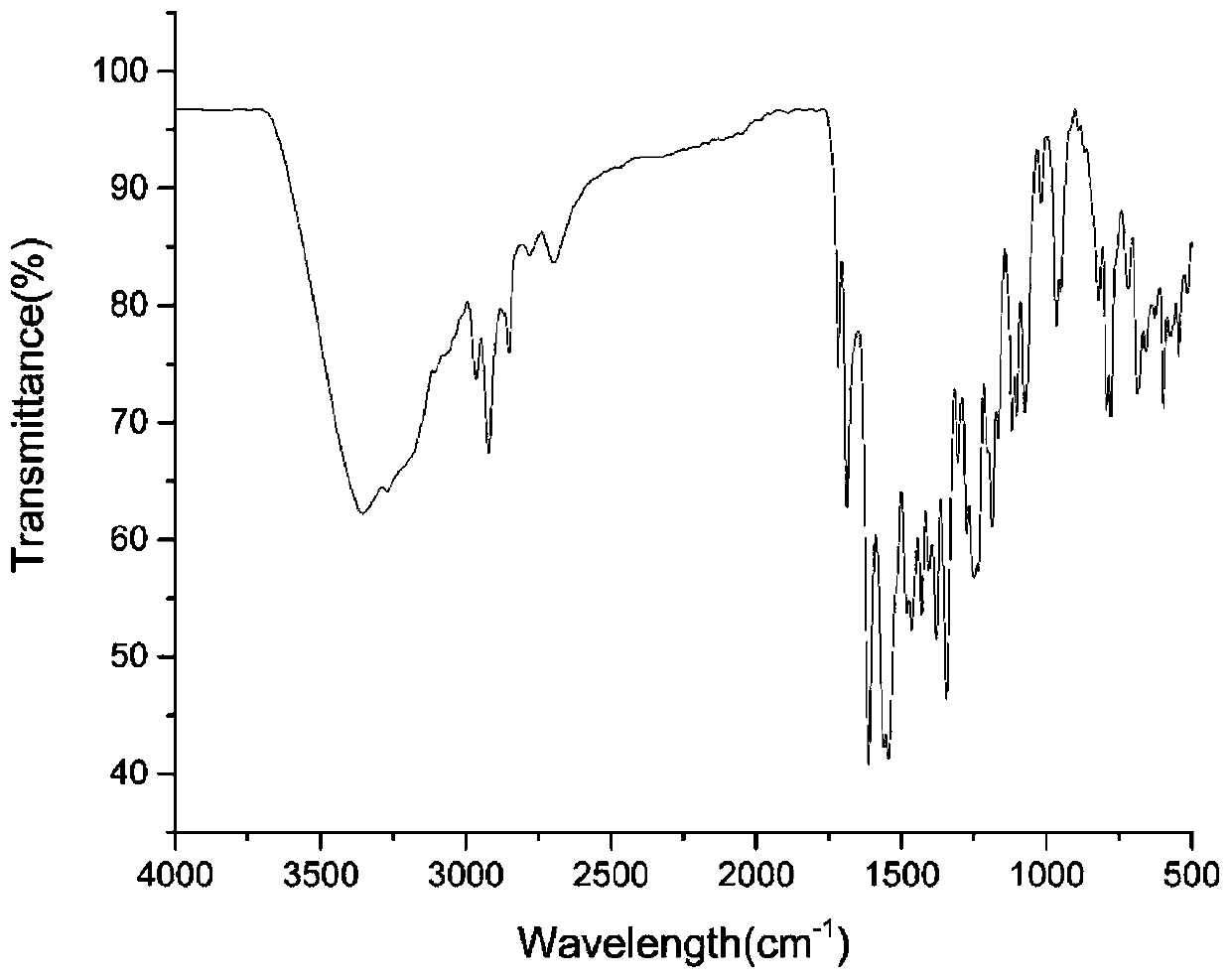

[0056] This embodiment synthesizes the reactive dyes of high fixation rate different cation groups, and its structural formula is:

[0057]

[0058] (1) Preparation of pyridine quaternary ammonium salt: Dissolve 11.6g (0.1mol) 2-chloroethylamine hydrochloride in deionized water, add 24.1mL (0.3mol) pyridine in a 500mL three-necked flask, stir with a magnetic stirrer, and Reflux at 95°C for 3h. The aqueous layer was acidified to pH 2 using concentrated hydrochloric acid, rotovapped under vacuum to form a slurry, the slurry was added dropwise to isopropanol, and the solidified product was filtered, washed with acetone, and dried.

[0059] (2) Preparation of aromatic quaternary ammonium salt (3-amino-N,N,N-trimethylbenzyl ammonium sulfate solution): Add 15g (0.1mol) m-aminoacetanilide into a three-necked flask, add 150mL Stir the deionized water until completely dissolved, then add 33.6g (0.4mol) NaHCO 3 . At room temperature, 37.23 mL (0.4 mol) of dimethyl sulfate (DMS) wa...

Embodiment 2

[0066] This embodiment synthesizes the reactive dyes of high fixation rate different cation groups, and its structural formula is:

[0067]

[0068] (1) Preparation of pyridine quaternary ammonium salt: Dissolve 11.6g (0.1mol) 2-chloroethylamine hydrochloride in deionized water, add 24.1mL (0.3mol) pyridine in a 500mL three-necked flask, stir with a magnetic stirrer, and Reflux at 95°C for 3h. Concentrated hydrochloric acid was used to acidify the aqueous layer to pH 2, and rotary evaporated under vacuum to form a slurry. The slurry was added dropwise to isopropanol, and the solidified product was filtered, washed with acetone, and dried to obtain a pyridinium quaternary ammonium salt.

[0069] (2) Preparation of aromatic quaternary ammonium salt (3-amino-N,N,N-trimethylbenzyl ammonium sulfate solution): Add 15g (0.1mol) m-aminoacetanilide into a three-necked flask, add 150mL Stir the deionized water until completely dissolved, then add 33.6g (0.4mol) NaHCO 3 . At room t...

Embodiment 3

[0075] This embodiment synthesizes the reactive dyes of high fixation rate different cation groups, and its structural formula is:

[0076]

[0077] (1) Preparation of pyridine quaternary ammonium salt: Dissolve 11.6g (0.1mol) 2-chloroethylamine hydrochloride in deionized water, add 24.1mL (0.3mol) pyridine in a 500mL three-necked flask, stir with a magnetic stirrer, and Reflux at 95°C for 3h. The aqueous layer was acidified to pH 2 using concentrated hydrochloric acid, rotovapped under vacuum to form a slurry, the slurry was added dropwise to isopropanol, and the solidified product was filtered, washed with acetone, and dried.

[0078] (2) Preparation of aromatic quaternary ammonium salt (3-amino-N,N,N-trimethylbenzyl ammonium sulfate solution): Add 15g (0.1mol) m-aminoacetanilide into a three-necked flask, add 150mL Stir the deionized water until completely dissolved, then add 33.6g (0.4mol) NaHCO 3 . At room temperature, 37.23 mL (0.4 mol) of dimethyl sulfate (DMS) wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com