Low-permeability oil reservoir water injection well decompression and augmented injection agent and preparation method thereof

A water injection well, low permeability technology, applied in chemical instruments and methods, drilling composition, etc., can solve the problems of reduced interfacial tension, unfavorable film-like adhesion oil removal, easy formation of fingering, etc., to improve rock wetness. Wet, reduce water injection friction and capillary resistance, good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Embodiment 1 A kind of pressure-reducing and injection-increasing agent for water injection wells in low-permeability reservoirs

[0035] The ingredients and their parts by weight are: 50 parts of dehydrorosin-type surfactant, 4 parts of dodecyl dimethyl hydroxypropyl phosphate betaine, 5 parts of cocamidopropyl betaine, polyoxyethylene quaternary Add 18 parts of ammonium salt, 5 parts of cetyl alcohol, and ethanol to 100 parts;

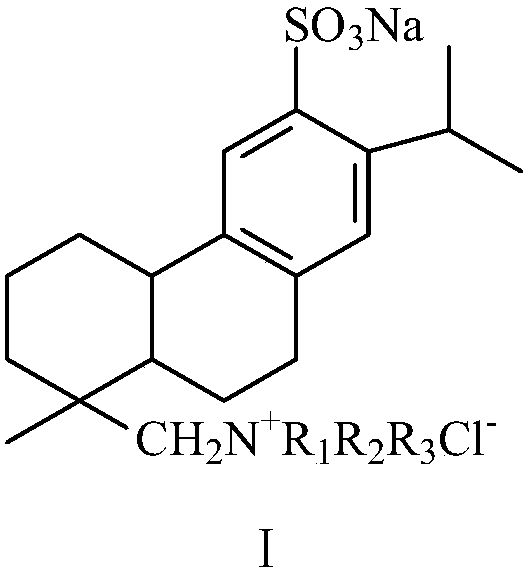

[0036] Described dehydroabietic surfactant structural formula is:

[0037]

[0038] In formula Ⅰ, R 1 and R 2 is a methyl group, R 3 For dodecyl.

[0039] The preparation method of described dehydroabietic type surfactant is, carries out as follows:

[0040] (1) Dissolve dehydroabietamine in absolute ethanol with 1.8 times its weight, slowly add dodecane bromide, and then reflux at 85°C for 24 hours;

[0041] (2) Cool down to 30°C, add iodomethane and stir in the dark for 12 hours, remove ethanol and unreacted alkanes by rotary evaporat...

Embodiment 2

[0047] Example 2 A depressurization and injection enhancement agent for water injection wells in low-permeability reservoirs

[0048] The ingredients and their parts by weight are: 52 parts of dehydrorosin-type surfactant, 3 parts of dodecyl dimethyl hydroxypropyl phosphate betaine, 4 parts of cocamidopropyl betaine, polyoxyethylene quaternary Add 22 parts of ammonium salt, 8 parts of cetyl alcohol, and ethanol to 100 parts;

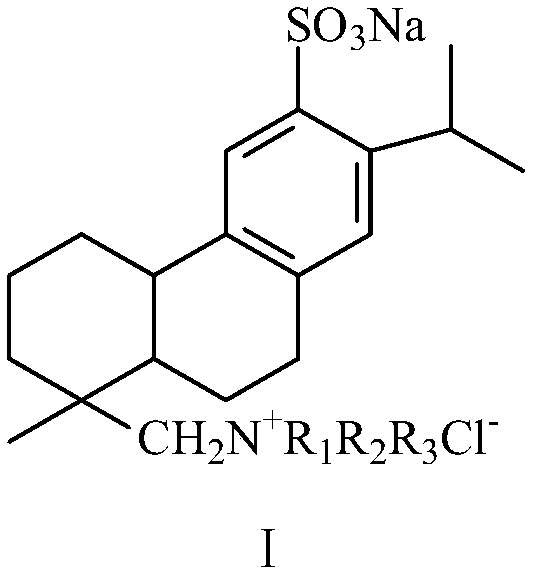

[0049] Described dehydroabietic surfactant structural formula is:

[0050]

[0051] In formula Ⅰ, R 1 and R 2 is a methyl group, R 3 For octane.

[0052] The preparation method of described dehydroabietic type surfactant is, carry out in steps as follows:

[0053] (1) Dissolve dehydroabietamine in absolute ethanol 1.5 times its weight, slowly add bromooctane, and then reflux at 80°C for 26 hours;

[0054] (2) Cool down to 35°C, add iodomethane and stir in the dark for 10 hours, remove ethanol and unreacted alkanes by rotary evaporation, and obta...

Embodiment 3

[0060] Embodiment 3 A kind of pressure-reducing and injection-increasing agent for water injection wells in low-permeability reservoirs

[0061] The ingredients and their parts by weight are: 55 parts of dehydrorosin-type surfactant, 5 parts of dodecyl dimethyl hydroxypropyl phosphate betaine, 6 parts of cocamidopropyl betaine, polyoxyethylene quaternary Add 18 parts of ammonium salt, 8 parts of cetyl alcohol, and ethanol to 100 parts;

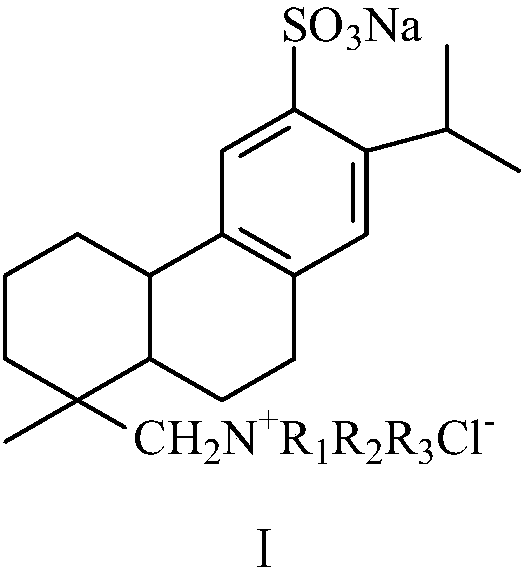

[0062] Described dehydroabietic surfactant structural formula is:

[0063]

[0064] In formula Ⅰ, R 1 and R 2 is a methyl group, R 3 For hexadecyl.

[0065] The preparation method of described dehydroabietic type surfactant is, carry out in steps as follows:

[0066] (1) Dissolve dehydroabietamine in absolute ethanol 2.0 times its weight, slowly add hexadecane bromide, and then reflux at 90°C for 20 hours;

[0067] (2) Cool down to 25°C, add iodomethane and stir in the dark for 15 hours, remove ethanol and unreacted alkanes by rotary ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com