Starting method of ethylene tar boiling bed-fixed bed combination process

A technology of ethylene tar and fixed bed, which is applied in tar processing, petroleum industry, hydrotreating process, etc., and can solve problems such as differences in start-up methods, cumbersomeness, and differences in properties between ethylene tar and coal tar

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

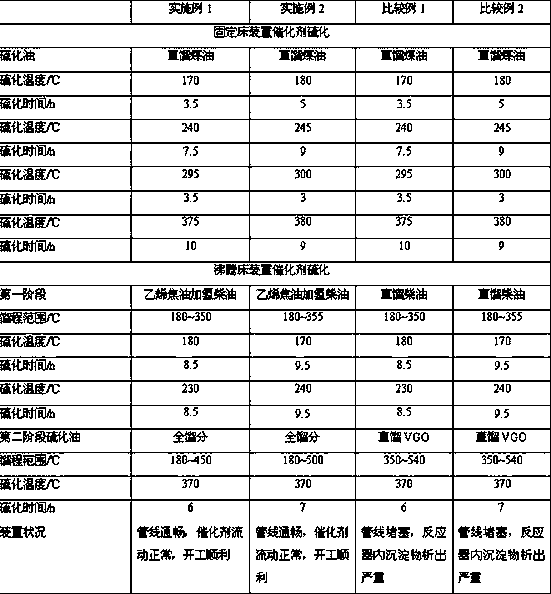

Embodiment 1

[0064] In Example 1, ethylene tar 1 in Table 1 is used as the raw material, which is a relatively heavy ethylene tar raw material. The start-up method of the present invention is adopted. The properties of the medium ethylene tar raw material are shown in Table 1. The ebullating bed hydrogenation device is equipped with an ebullating bed hydrogenation reactor, and the ebullating bed hydrogenation reactor is filled with FEC catalyst, and the specific properties of the catalyst are shown in Table 2. The fixed-bed hydrogenation device is provided with two fixed-bed hydrogenation reactors, and the two fixed-bed hydrogenation reactors are connected in series, respectively filled with FMJ-2 and FMJ-3 catalysts, and the specific properties of the catalysts are shown in Table 3. The initial vulcanized oil of the fixed-bed hydrogenation reactor is straight-run kerosene, which is directly obtained by distillation of petroleum-based crude oil. The vulcanizing agent is DMDS. The maximum in...

Embodiment 2

[0066] It is basically the same as Example 1, except that the raw material is ethylene tar raw material with relatively good quality, the specific properties are shown in Table 2, and the specific starting operating conditions are different, see Table 5 for specific starting operating conditions.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com