Bio-enzyme curing material integrated road paving construction method

A technology for solidifying materials and road construction, applied in the direction of roads, roads, road repair, etc., can solve the problems of unknown construction technology and untargetedness, and achieve the effect of avoiding ecological and environmental damage, significant economic benefits, and reducing investment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0067] The present invention will be further described below.

[0068] A construction method for paving roads integrated with bio-enzyme-solidified materials, including the design of the mix ratio of bio-enzyme-solidified materials and its integrated paving construction method, including the following steps:

[0069] (1) Mixing ratio design of bio-enzyme solidified materials

[0070] 1.1) Selection of raw materials

[0071] Biological enzyme: a transparent brown liquid compound enzyme product produced by Nature Plus, Inc. of the United States (distributed by Tairan Lutong Technology Co., Ltd.), which belongs to the biological enzyme soil stabilizer.

[0072] Cement and lime: Ordinary Portland cement is used, and the cement grade is not lower than No. 32.5; the quality of the lime used must meet the national grade 3 lime standard, that is, the calcium and magnesium content must be greater than 75%.

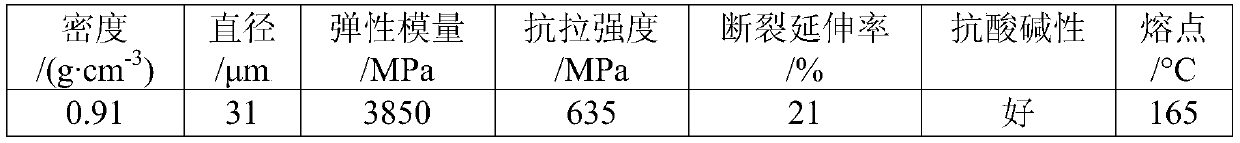

[0073] Flexible fiber: Polypropylene monofilament flexible fiber is used, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com