Quick-split type box-shaped section steel concrete column-H-shaped steel concrete beam connection node

A technology for concrete columns and concrete beams, applied in the direction of columns, joists, girders, etc., can solve the problems of weakening the structural strength of box-shaped steel columns, decreasing the stability of box-shaped steel columns, and the large amount of welding work for connecting plates, etc. On-site construction efficiency, reduced on-site welding volume, and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention is further described below in conjunction with accompanying drawing:

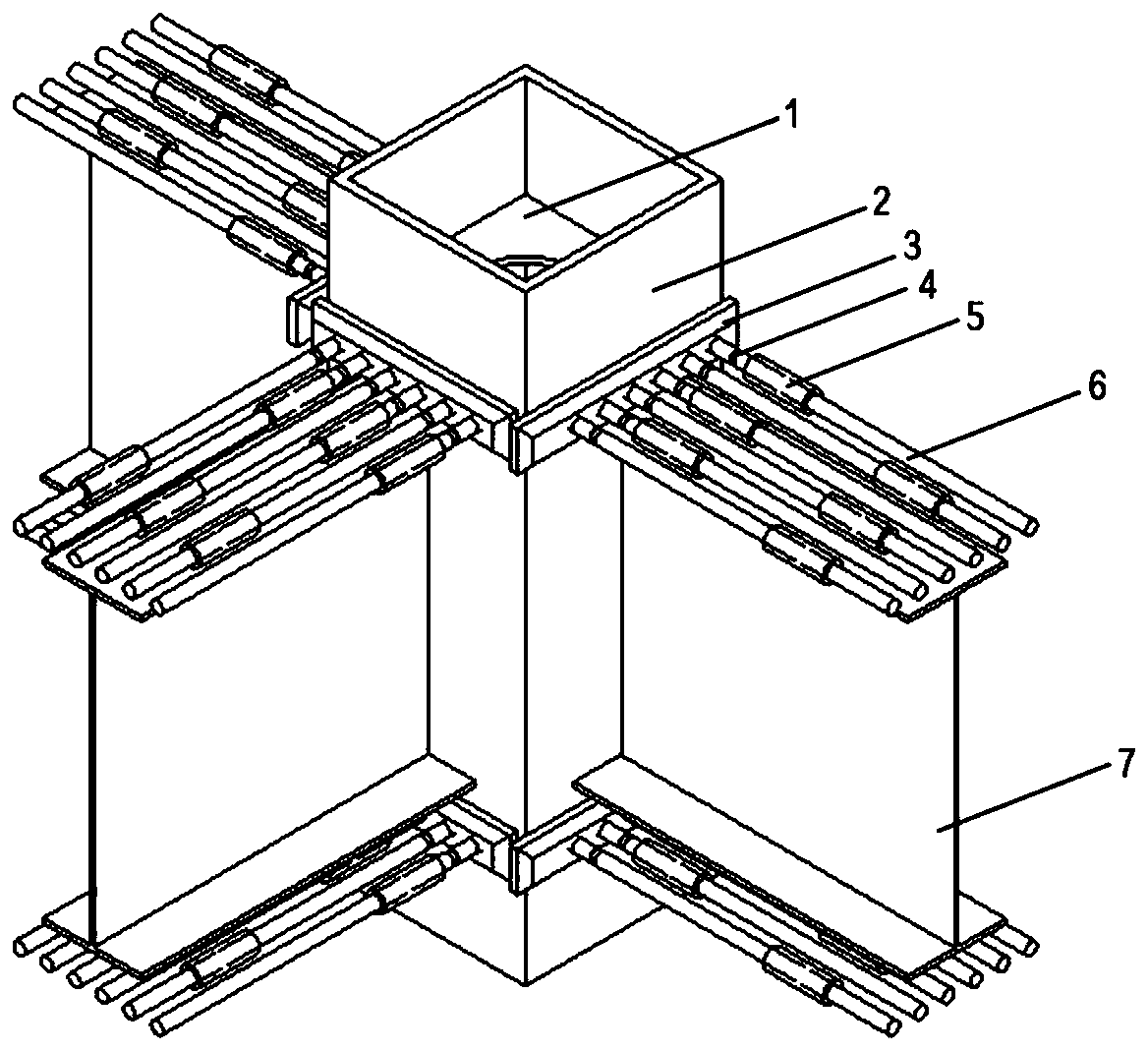

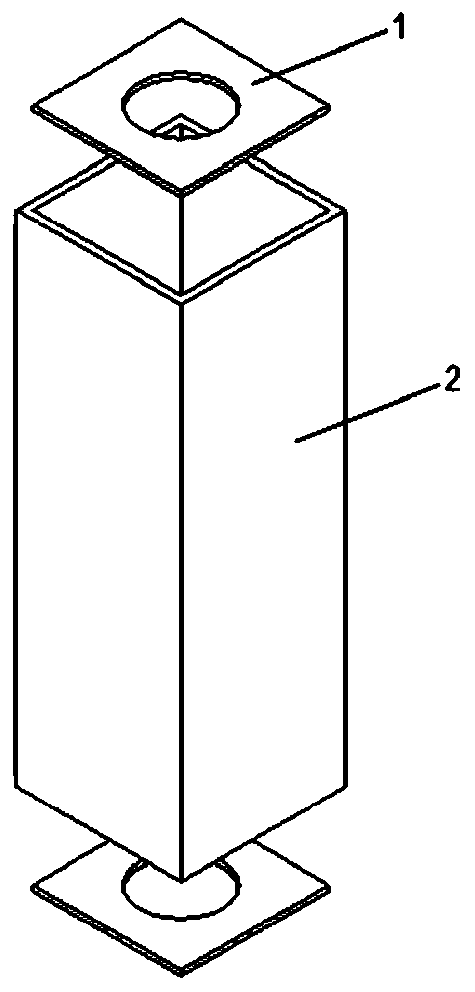

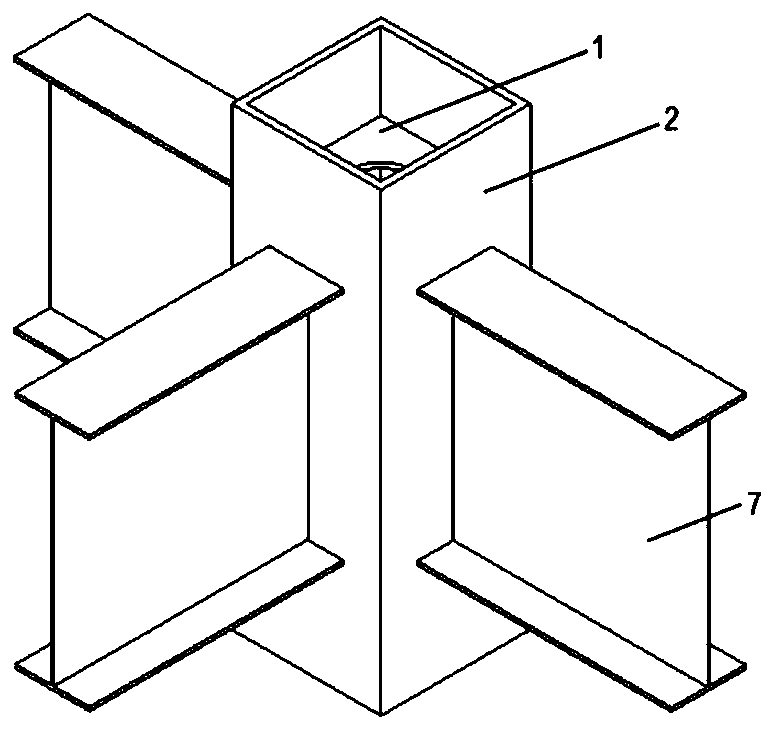

[0027] see Figure 1 to Figure 8 , a quick-assembled box-shaped steel concrete column-H-shaped steel concrete beam connection node, including box-shaped steel columns 2, H-shaped steel beams 7, connecting plates 3 and reinforcing ribs; several H-shaped steel beams 7 are vertically fixed on the box On the outer wall of the shaped steel column 2, connecting plates 3 are fixedly arranged on the side walls of the box-shaped steel column 2 above and below each H-shaped steel beam 7, and several threaded holes are arranged on the connecting plate 3, and all connecting plates 3 A number of reinforcing ribs are arranged vertically on the top. The number of H-shaped steel beams 7 is three.

[0028] The reinforcing ribs include double-ended studs 4, steel bar connectors 5 and steel bars 6; Connection, the other end of the double-ended stud 4 is threaded with the connecting plate 3; the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com