A kind of thermal insulation formwork of external wall without demolition and preparation method thereof

An external wall insulation and formwork technology, which is applied in the fields of formwork/formwork components, formwork/formwork/work frame, and on-site preparation of building components, can solve the problem of low production efficiency, long maintenance cycle of insulation boards, and easy breakage and other problems to achieve the effect of improving usability, improving workability and water retention, and enhancing fire resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

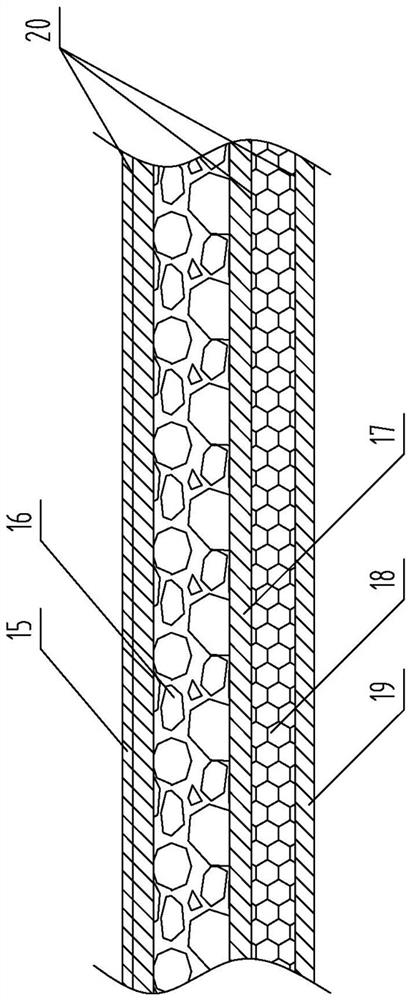

[0057] In this example, the non-demolition-free exterior wall insulation formwork is obtained through the following steps:

[0058] (1) Preparation of high-strength slurry: high-strength slurry is prepared by mixing water and the first ash material. The mass ratio of water and the first ash material is 1:2. The first ash material is made of Portland cement, sulfur-aluminum cement, Composed of fly ash, quartz sand, water repellent, calcium formate, VAE emulsion and admixtures, Portland cement accounts for 20% by mass of the first ash material, and sulfur-aluminum cement accounts for 5.5% by mass of the first ash material , fly ash accounts for 8% by mass of the first ash material, quartz sand accounts for 64% by mass of the first ash material, water-repellent agent accounts for 0.1% by mass of the first ash material, and calcium formate accounts for 0.1% by mass of the first ash material The mass percentage is 0.4%, the VAE emulsion accounts for 1% of the mass percentage of the...

Embodiment 2

[0071] The differences between this embodiment and Embodiment 1 are:

[0072] In step (1), the mass ratio of water to the first ash is 1:4, Portland cement accounts for 22% by mass of the first ash, and sulfur-aluminum cement accounts for 7% by mass of the first ash, Fly ash accounts for 5% by mass of the first ash material, quartz sand accounts for 63% by mass of the first ash material, water repellent accounts for 0.1% by mass of the first ash material, and calcium formate accounts for the mass percentage of the first ash material The percentage is 0.5%, the VAE emulsion accounts for 1.2% of the mass percentage of the first ash material, and the admixture accounts for 1.2% of the mass percentage of the first ash material;

[0073] In step (2), the volume ratio of composite slurry to lightweight aggregate is 1:5, the mass ratio of water to the second ash is 1:4, and the mass percentage of Portland cement in the second ash is 62 %, the mass percentage of high alumina cement i...

Embodiment 3

[0076] The differences between this embodiment and Embodiment 1 are:

[0077] In step (1), the mass ratio of water to the first ash is 1:3, Portland cement accounts for 21% by mass of the first ash, and sulfur-aluminum cement accounts for 6% by mass of the first ash, Fly ash accounts for 5% of the mass percentage of the first ash material, quartz sand accounts for 65.6% of the mass percentage of the first ash material, water-repellent agent accounts for 0.1% of the mass percentage of the first ash material, and calcium formate accounts for the mass percentage of the first ash material The percentage is 0.3%, the VAE emulsion accounts for 1% of the mass percentage of the first ash material, and the admixture accounts for 1% of the mass percentage of the first ash material;

[0078] In step (2), the volume ratio of composite slurry to lightweight aggregate is 1:3.5, the mass ratio of water to the second ash is 1:3, and the mass percentage of Portland cement in the second ash is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com