Energy-saving environment-friendly multifunctional double-vertical-tank roller drying machine

A drum dryer, energy-saving and environment-friendly technology, applied in the direction of dryer, drying, dryer combination, etc., can solve the problems of waste, low utilization rate, single function, etc., to increase hot air treatment room, save time, Even drying effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

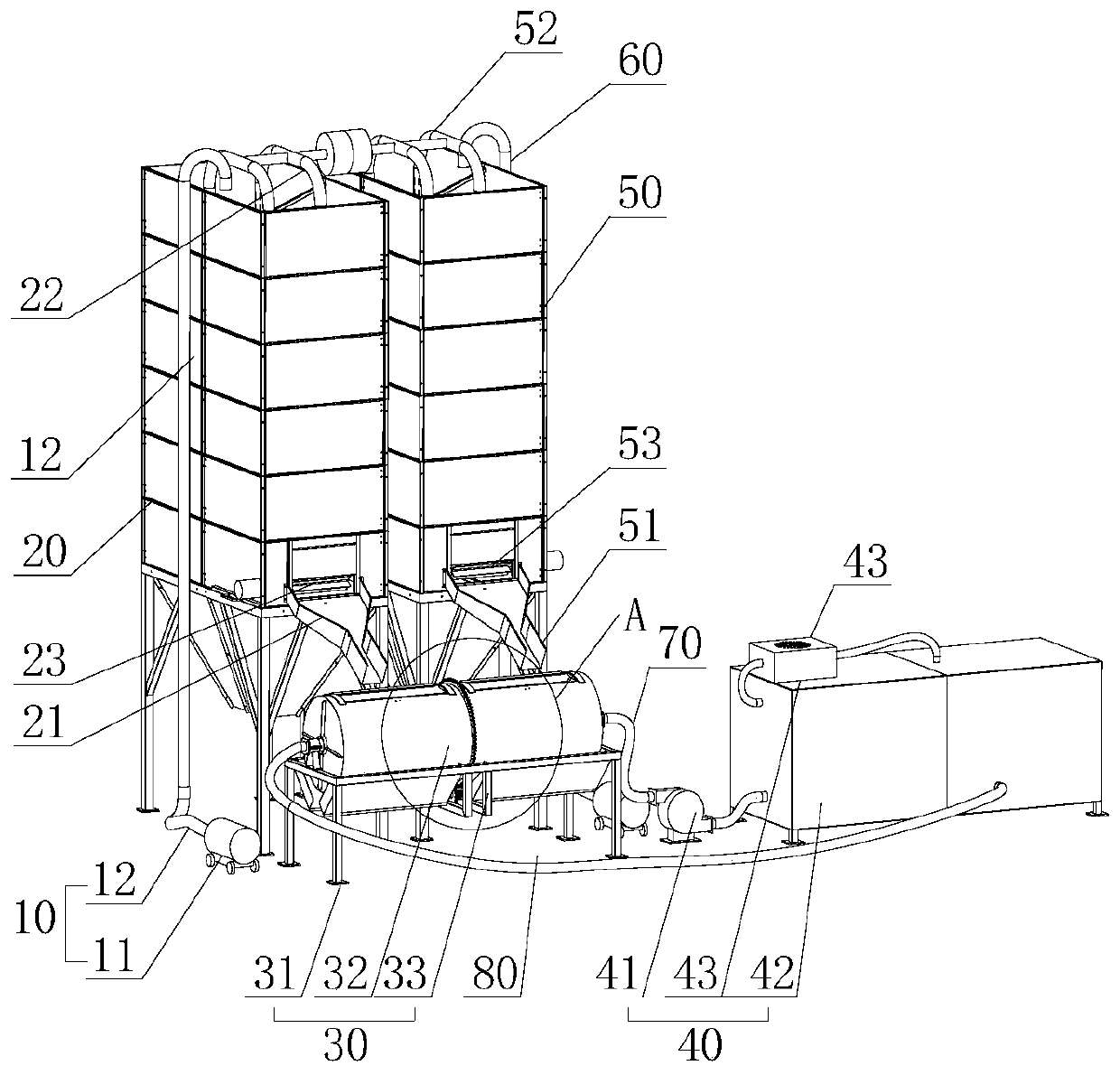

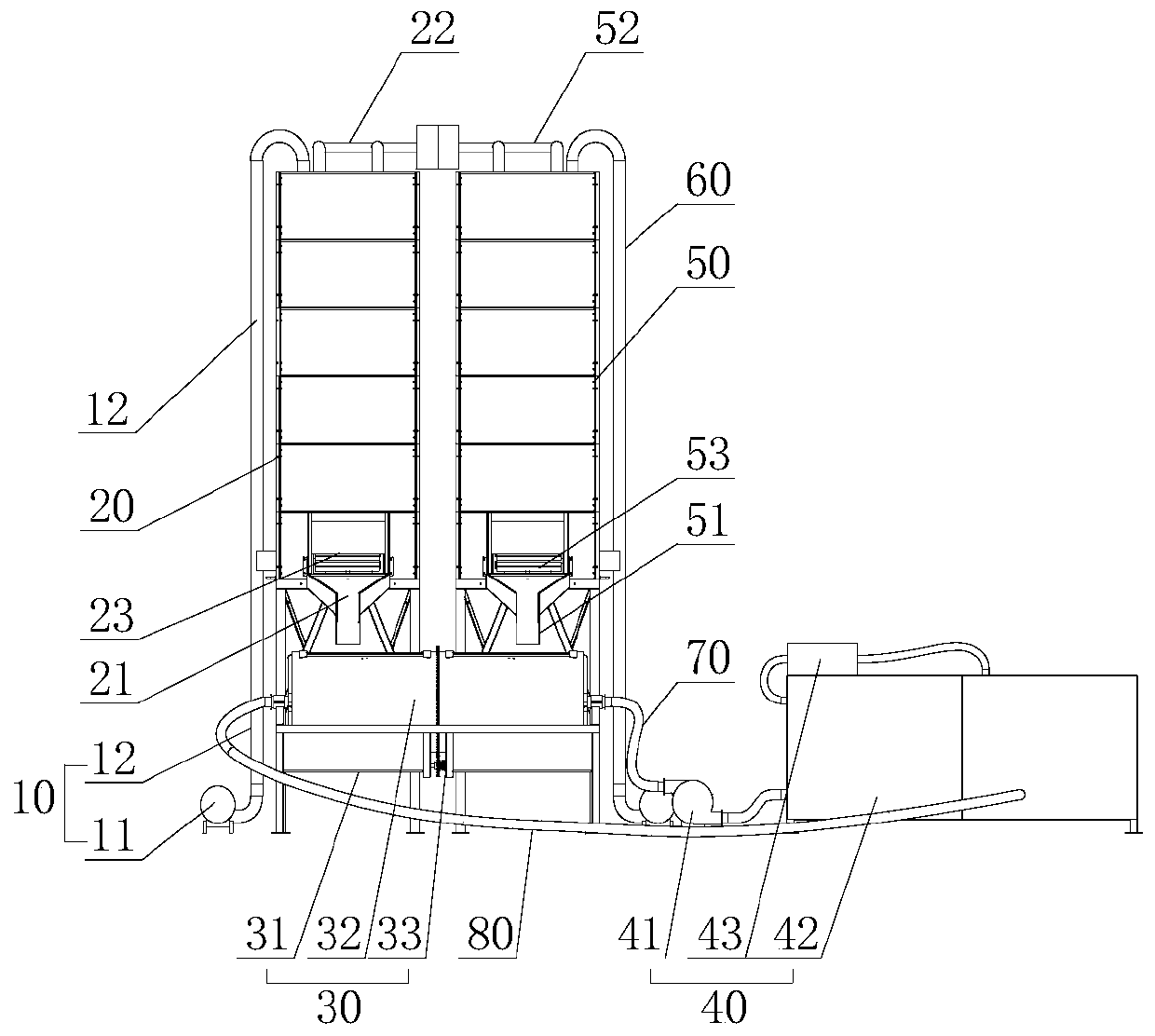

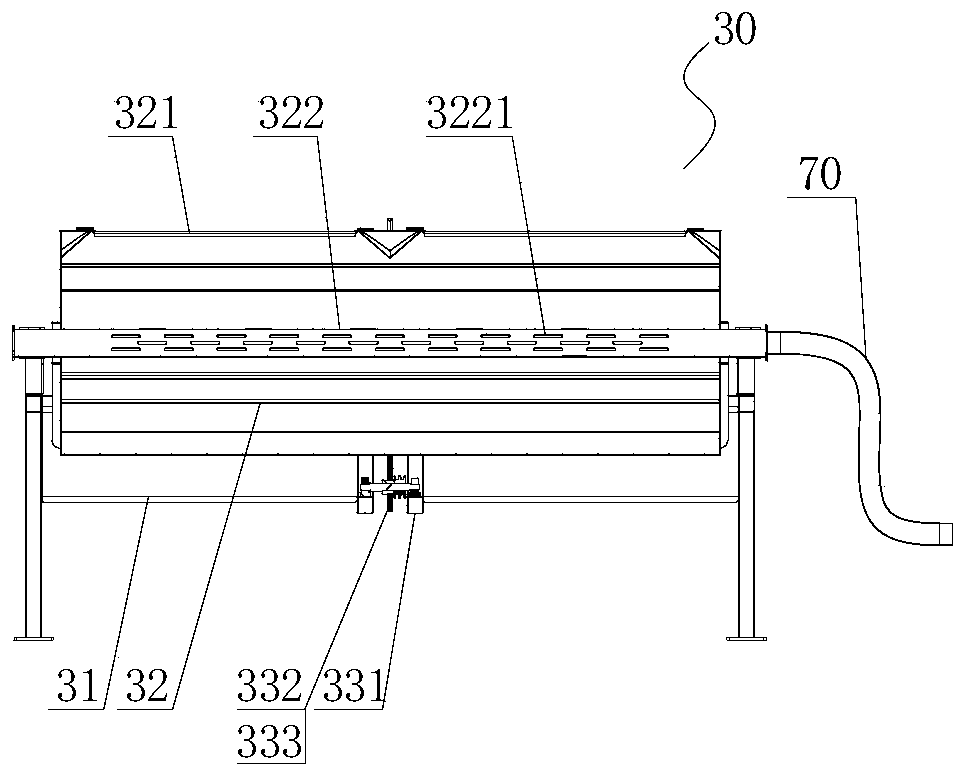

[0034] Such as figure 1 , figure 2 As shown, an energy-saving and environment-friendly multifunctional double-vertical drum dryer according to the present invention includes a cleaning device 10, a vertical wet material tank 20, a drum drying device 30, a hot air treatment device 40, a vertical drying Material tank 50; the cleaning device 10 includes a cleaning machine 11 and a wet material lifting device 12 connected to the outlet of the cleaning machine 11, and the discharge port of the wet material lifting device 12 corresponds to the vertical wet material tank 20 The top tank opening; the bottom of the vertical wet material tank 20 and the vertical dry material tank 50 are provided with unloading gates 21, 51; the vertical dry material tank 50 is provided with a dry material lifting device 60, so The bottom opening of the dry material lifting device 60 is adjacent to the drum drying device 30, and the discharge port of the dry material lifting device 60 corresponds to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com