A cyanide-free separation process of low-grade tin-lead-zinc polymetallic sulfide mineral lead-zinc

A low-grade, multi-metal technology, applied in flotation, solid separation, wet separation, etc., can solve problems such as large safety risks and environmental protection hazards, to eliminate safety, increase production costs, improve concentrate grade and recovery rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

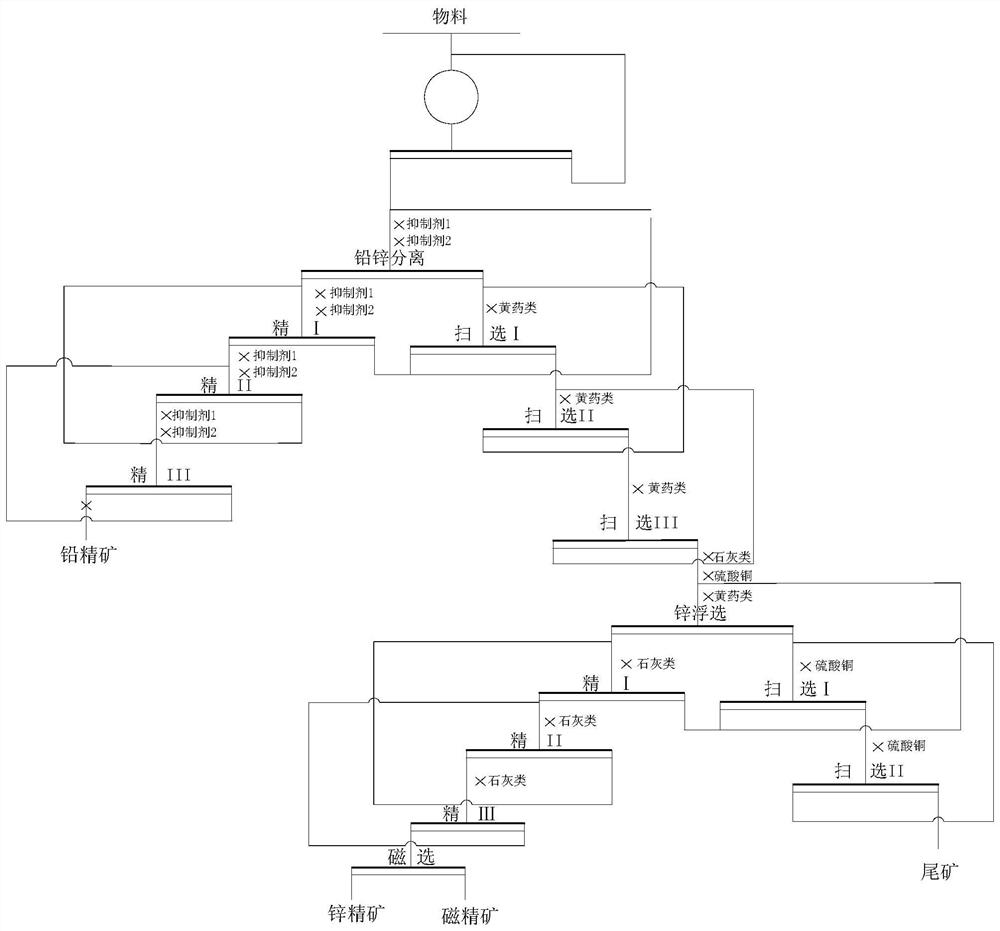

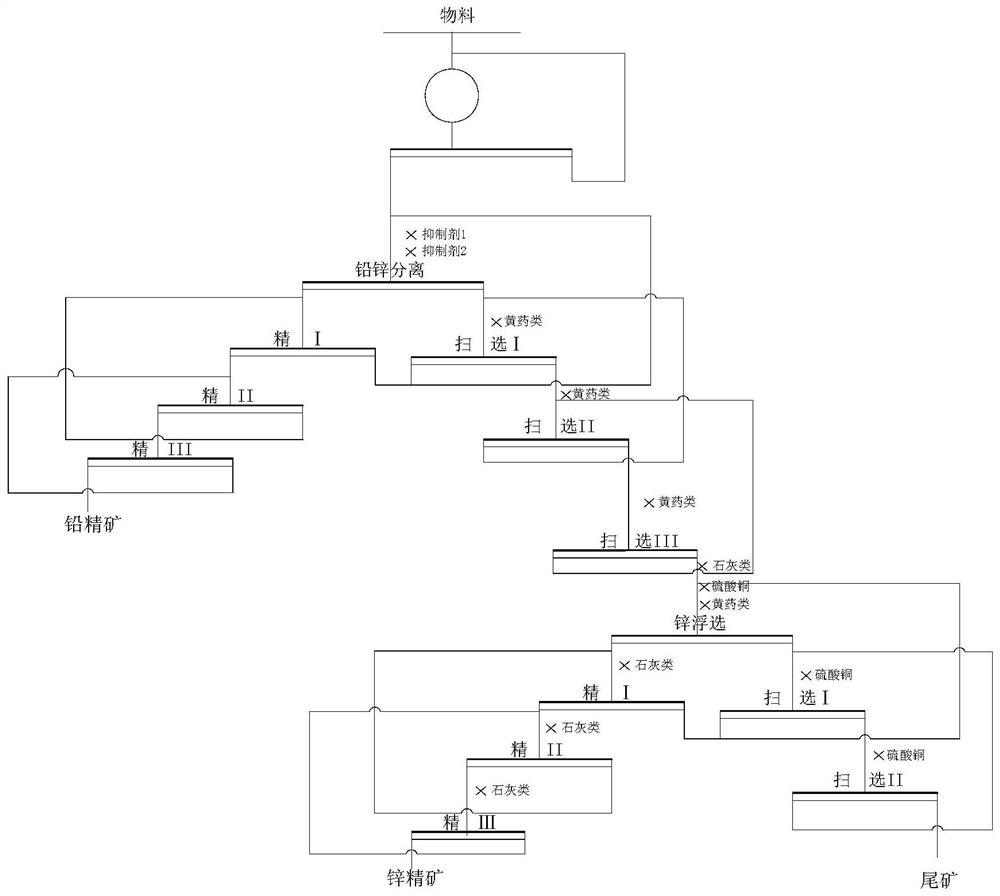

Embodiment 1

[0032] This embodiment provides a cyanide-free separation process for low-grade tin-lead-zinc polymetallic sulfide mineral lead-zinc. The tin grade in the raw ore is 0.54%, the lead grade is 0.23%, the zinc grade is 2.0%, and the pyrrhotite content is 8%, and pyrite accounts for 10%; among them, Pb in lead sulfide accounts for 85% of the lead metal content, and Zn in zinc sulfide accounts for 98% of the zinc metal content;

[0033] The specific steps of the sorting process are:

[0034] (1) Grinding: After the low-grade tin polymetallic sulfide minerals are ground and classified, the qualified particle size of -200 mesh enters the lead-zinc separation and flotation operation;

[0035](2) Lead separation flotation: In the lead-zinc flotation separation operation, the process of "one rough, three fine and three sweeps" is adopted, and inhibitor 1 and inhibitor are added respectively in rough selection, selection Ⅰ, selection Ⅱ and selection Ⅲ 2 As a zinc mineral inhibitor, it i...

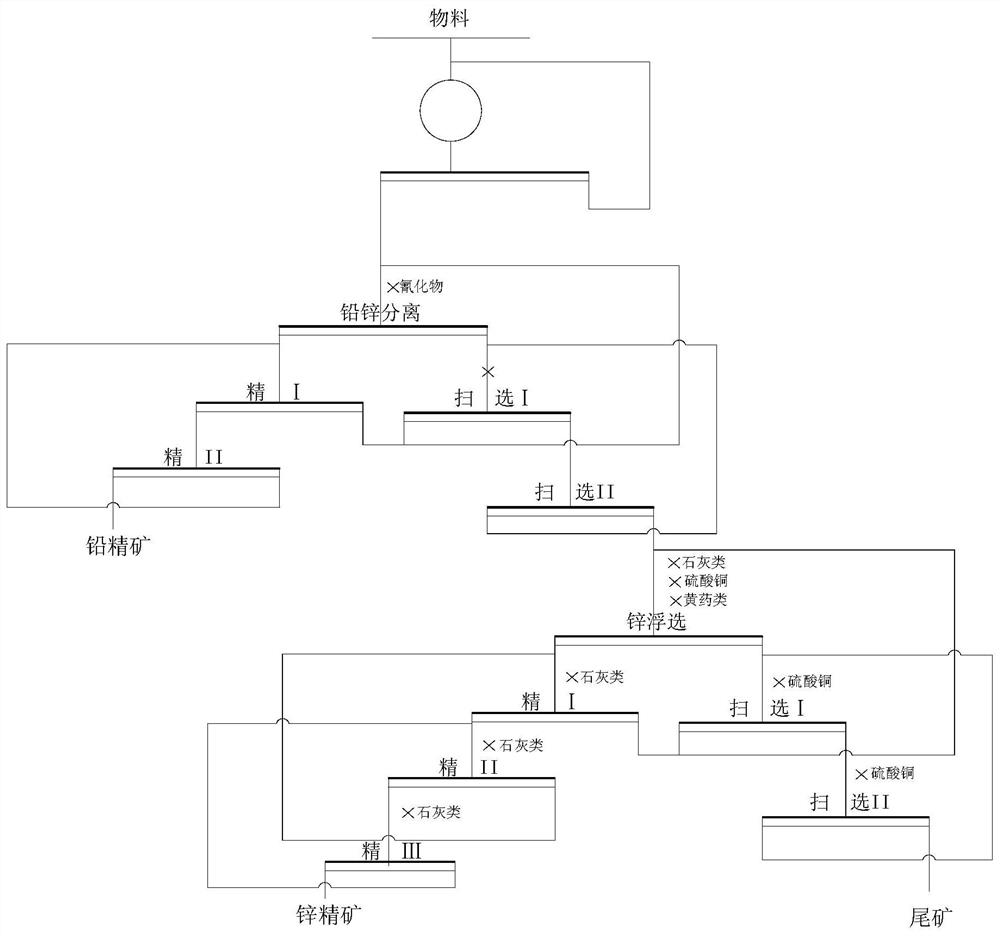

Embodiment 2

[0042] This embodiment provides a cyanide-free separation process for low-grade tin-lead-zinc polymetallic sulfide minerals lead and zinc. The tin grade in the raw ore is 0.25%, the lead grade is 0.15%, the zinc grade is 1.4%, and the pyrrhotite content is 4%, and pyrite accounts for 8%; among them, Pb in lead sulfide accounts for 70% of the lead metal content, and Zn in zinc sulfide accounts for 90% of the zinc metal content;

[0043] The specific steps of the sorting process are:

[0044] (1) Grinding: After the low-grade tin polymetallic sulfide minerals are ground and classified, the qualified particle size of -200 mesh enters the lead-zinc separation and flotation operation;

[0045] (2) Lead separation flotation: In the lead-zinc flotation separation operation, the process of "one rough, three fine and three sweeps" is adopted, and inhibitor 1 and inhibitor are added respectively in rough selection, selection Ⅰ, selection Ⅱ and selection Ⅲ 2 As a zinc mineral inhibitor,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com