Method for coating open type UV paint on woodware

An open, wooden technology, used in devices and coatings that apply liquid to the surface, can solve the problems of high spraying technology requirements, low construction efficiency, high air humidity, etc., achieve excellent physical and chemical properties, improve Pore penetration and opening, and high productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

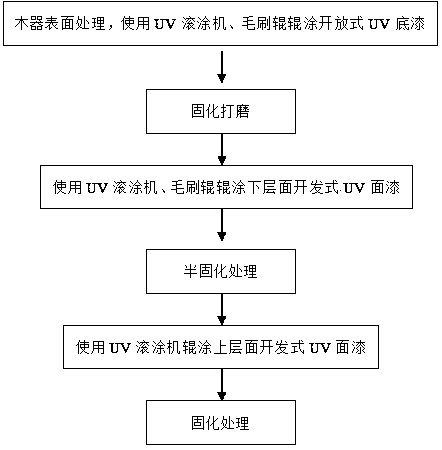

[0015] refer to figure 1 , a kind of method for coating open UV lacquer on woodenware, comprises the steps:

[0016] S1. Grind the surface of the wood to be coated, use #240 mesh sandpaper to sand the surface of the wood, you can use a sander for machine sanding, and then dispose of the sanded dust, you can use a dust remover to complete it; after completion, use UV The roller coating machine rolls the open UV primer on the surface of the wood. The hardness of the rubber roller of the UV roller coating machine is preferably 10 degrees (Rockwell hardness, the same below), and the single-roller process is used; then the wood is coated with a brush roller The open UV primer on the top can force the paint into the hole and improve the opening of the hole;

[0017] S2, curing and polishing the open UV primer coated on the woodenware, using a UV curing machine for curing, preferably using #600 mesh sandpaper for sanding, and using an electrostatic precipitator or point-to-point ded...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com