A method of producing a polypropylene composition

A polypropylene composition and polypropylene technology are applied in the field of polypropylene composition production, which can solve the problems of gloss loss, no patent disclosure of polymerized ethylene and α-olefin comonomers, and stay-sequential synthesis.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

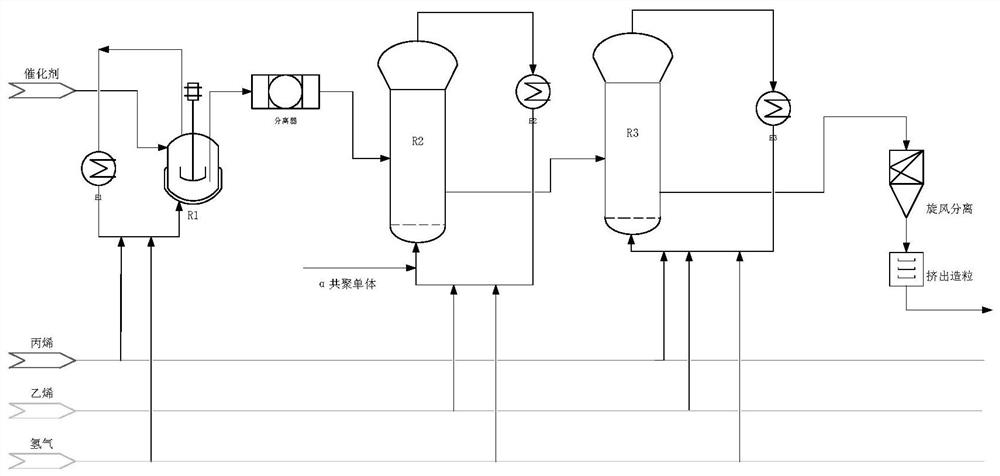

[0060] exist figure 1 A method for producing a polypropylene composition is shown to produce a polypropylene composition. Under the condition that the initial temperature is 30° C. and the stirred tank reactor R1 maintains a vacuum, the stirred tank reactor R1 with a volume of 1.1 L Carry out the catalyst addition operation. The catalyst is a Ziegler-Natta catalyst, and the dosage is 58-60 mg each time. At the same time, 0.13-0.14 ml of the corresponding external electron donor dicyclopentyldimethoxysilane (DCPDMS) is added through the catalyst pipeline, and auxiliary Catalyst Triethylaluminum (TEA) 0.83-0.94ml. Use 150-250 ml of n-heptane as a solvent, and feed the catalyst into the stirred tank reactor R1 through the catalyst pipeline. Turn on the stirring and maintain the rotation speed at 500 rpm. Ensure that the liquid in the kettle is fully turbulent, add a certain amount of hydrogen through the hydrogen pipeline, and add propylene monomer through the propylene pipeli...

Embodiment 2

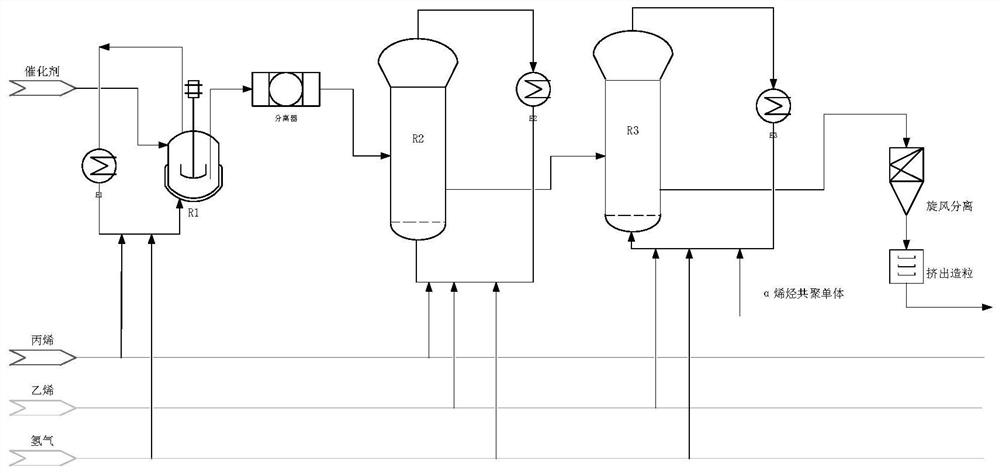

[0062] exist figure 2A method for producing a polypropylene composition is shown to produce a polypropylene composition. Under the condition that the initial temperature is 30° C. and the stirred tank reactor R1 maintains a vacuum, the stirred tank reactor R1 with a volume of 1.1 L Carry out the catalyst addition operation. The catalyst is a Ziegler-Natta catalyst, and the dosage is 58-60 mg each time. At the same time, 0.13-0.14 ml of the corresponding external electron donor dicyclopentyldimethoxysilane (DCPDMS) is added through the catalyst pipeline, and auxiliary Catalyst Triethylaluminum (TEA) 0.83-0.94ml. Use 150-250ml of n-heptane as a solvent, and pour it into the stirred tank reactor R1 through the catalyst pipeline. Turn on the stirring and maintain the rotation speed at 500 rpm. Ensure that the liquid in the kettle is fully turbulent, add a certain amount of hydrogen, add propylene monomer, and maintain the system pressure at 1 bar. The residence time in the pr...

Embodiment 3

[0064] Under the condition that the initial temperature is 30° C. and the stirred tank reactor is maintained in vacuum, a gas-phase seed bed sodium chloride feeding operation is carried out in a stirred tank reactor with a volume of 1.1 L. Sodium chloride needs to be roasted at a high temperature of 600°C in a muffle furnace to remove impurities and water and oxygen. Add 150ml of solid sodium chloride, and vacuumize the reaction kettle to ensure good water and oxygen conditions. The catalyst is a Ziegler-Natta catalyst, and the dosage is 58-60 mg each time. At the same time, 0.13-0.14 ml of the corresponding external electron donor dicyclopentyldimethoxysilane (DCPDMS) and the cocatalyst triethyl Aluminum (TEA) 0.83 ~ 0.94ml. Add the catalyst into the stirred tank reactor, turn on the stirring, and maintain the rotation speed at 1000 rpm. Ensure that the seed bed in the kettle is fully turbulent, add a certain amount of hydrogen, add propylene monomer, and maintain the syste...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com