Lithium battery electrolyte solution resistant fluororubber composition and preparation method thereof

A fluororubber, lithium battery technology, applied in battery pack parts, circuits, electrical components, etc., can solve problems such as complex structure and poor bending precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

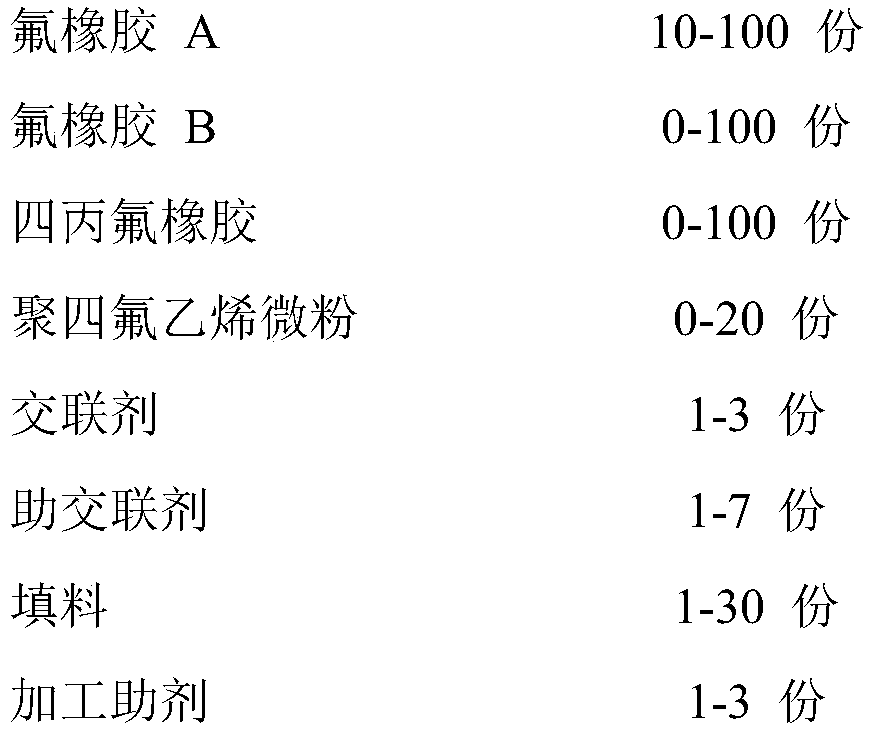

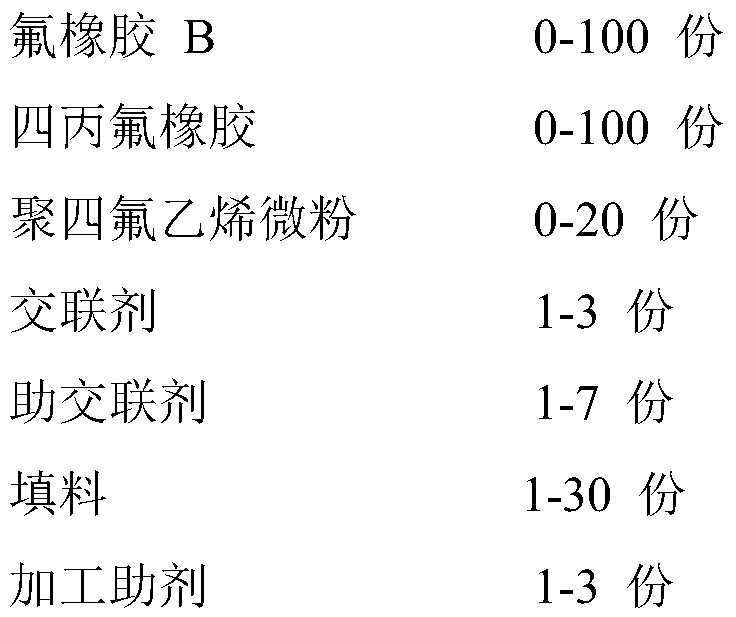

Method used

Image

Examples

Embodiment 1-8

[0026] The fluororubber A in Table 1 and tetrapropylene fluororubber or fluororubber B were masticated evenly on a two-roll mill and rolled, and then the crosslinking agent DBPH50, the auxiliary crosslinking agent TAIC S70, carbon black N990 and processing aid All auxiliary materials such as agent HT290 are pre-mixed evenly, and slowly added to the open mill. After all the powdery auxiliary materials are powdered, the wrapping rubber material is cut 5 times on the left and right, and then the triangular bag is made 10 times to fully mix the rubber and auxiliary materials. Uniform, then adjust the roller distance to release the sheet, the thickness is controlled at 6mm, and the fluororubber composition compound rubber resistant to lithium battery electrolyte is obtained. The entire mixing process is controlled within 10 minutes, and the roller temperature of the mill is controlled within 80 ° C. After the prepared mixed rubber was aged for 16 hours, it was re-milled and produced...

Embodiment 2

[0030]The physical and mechanical properties of the composition of Example 2 and the changes in the electrolyte solvent can be seen, and the composition material after using 10 parts of alkali-resistant fluororubber Viton ETP600S is completely immersed in the electrolyte solvent, at room temperature and at a temperature of 40 ° C Under the same conditions, after 168 hours, the volume change has decreased, its chemical resistance has been improved, and the physical and mechanical properties of tensile strength and elongation at break have also decreased. It can be seen that the use of alkali-resistant fluororubber Viton ETP600S can improve Electrolyte solvent resistance performance of fluororubber Viton GF600S.

[0031] The physical and mechanical properties of embodiment 3 and 4 compositions and the change in electrolyte solvent can be seen, and the composition material after using alkali-resistant fluororubber Viton ETP600S and polytetrafluoroethylene micropowder Zonyl MP1400 ...

Embodiment 7

[0033] The physical and mechanical properties of the composition of Example 7 and the changes in the electrolyte solvent can be seen. The composition material of 100 parts of tetrapropylene fluororubber Aflas X600 is completely immersed in the electrolyte solvent. After 168 hours, the volume change is about 20%, but the physical and mechanical properties change more than 50% in tensile strength and hardness. The compression set rate is 40%. From the perspective of seal design, it is not suitable for this working condition. under sealing application requirements.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com