High-brightness PMMA-ABS composite material and preparation method thereof

A composite material, ABS resin technology, applied in the field of ABS composite material and its preparation, high-brightness PMMA, can solve the problems of poor surface performance, inability to have gloss, poor scratch resistance, etc. Item parameters and conditions are easy to control, and the performance is stable and uniform.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

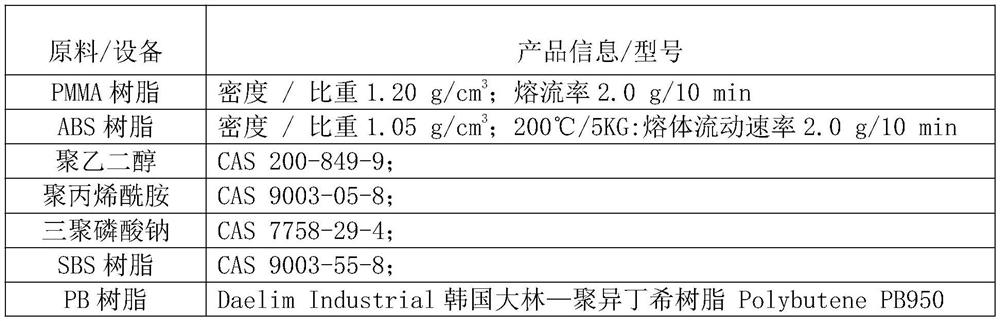

Method used

Image

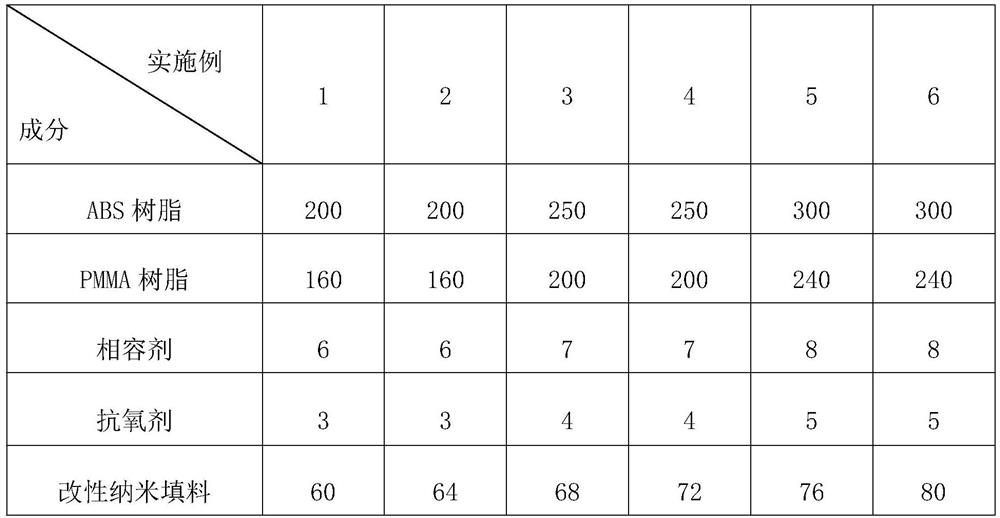

Examples

preparation example 1

[0054] A modified nano filler, the preparation steps of which are as follows:

[0055] a. Pretreatment: After preheating 100kg of nano-fillers to 70°C, place them in a 40% hydrogen peroxide aqueous solution by mass percentage, heat and stir them ultrasonically for 12.5min at an ultrasonic frequency of 20KHz, then filter and dry for 4min , the pretreated filler can be prepared;

[0056] The nano-filler is composed of nano-barium sulfate, nano-aluminum silicate and nano-silicon carbide in a weight ratio of 1:2:0.4;

[0057] b. Modification treatment: Mix and heat the pretreatment filler, dispersant, and modification liquid at a weight ratio of 1:0.15:5 for 37.5 minutes, control the heating temperature to 90°C, control the speed to 650r / min, filter and dry for 4 minutes, that is Modified nano fillers can be prepared; the dispersant is polyethylene glycol;

[0058] The modified solution is composed of sodium gluconate, sorbitol, and N,N-dimethylformamide in a weight ratio of 1:2...

preparation example 2

[0060] A modified nanofiller, the difference from Preparation Example 1 is that its preparation steps are as follows:

[0061] a. Pretreatment: After preheating 100kg of nano-fillers to 40°C, place them in 20% hydrogen peroxide aqueous solution by mass percentage, heat and stir them ultrasonically for 5 minutes, and then filter and dry them for 3 minutes at an ultrasonic frequency of 20KHz. The pretreatment filler can be prepared;

[0062] b. Modification treatment: Mix and heat the pretreatment filler, dispersant, and modified solution for 15 minutes, control the heating temperature to 60°C, control the rotation speed to 300r / min, filter and dry for 3 minutes, and the others are the same as in Preparation Example 1. A modified nano filler is prepared.

preparation example 3

[0064] A modified nanofiller, the difference from Preparation Example 1 is that its preparation steps are as follows:

[0065] a. Pretreatment: After preheating 100kg of nano-fillers to 60°C, place them in 30% hydrogen peroxide aqueous solution by mass percentage, heat and stir them ultrasonically for 10 minutes, and then filter and dry them for 3 minutes at an ultrasonic frequency of 20KHz. The pretreatment filler can be prepared;

[0066] b. Modification treatment: Mix and heat the pretreatment filler, dispersant, and modified liquid for 30 minutes, control the heating temperature to 80°C, control the rotation speed to 500r / min, filter and dry for 3 minutes, and the others are the same as in Preparation Example 1. A modified nano filler is prepared.

PUM

| Property | Measurement | Unit |

|---|---|---|

| gloss | aaaaa | aaaaa |

| gloss | aaaaa | aaaaa |

| gloss | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com