Overlapping curve heat-conducting glue label material with inflaming retarding function and preparation method thereof

A label material and thermally conductive adhesive technology, applied in instruments, adhesive types, non-polymer adhesive additives, etc., can solve the problems of hot electronic products, poor heat dissipation, and poor heat dissipation. The effect of high heat dissipation and strong insulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

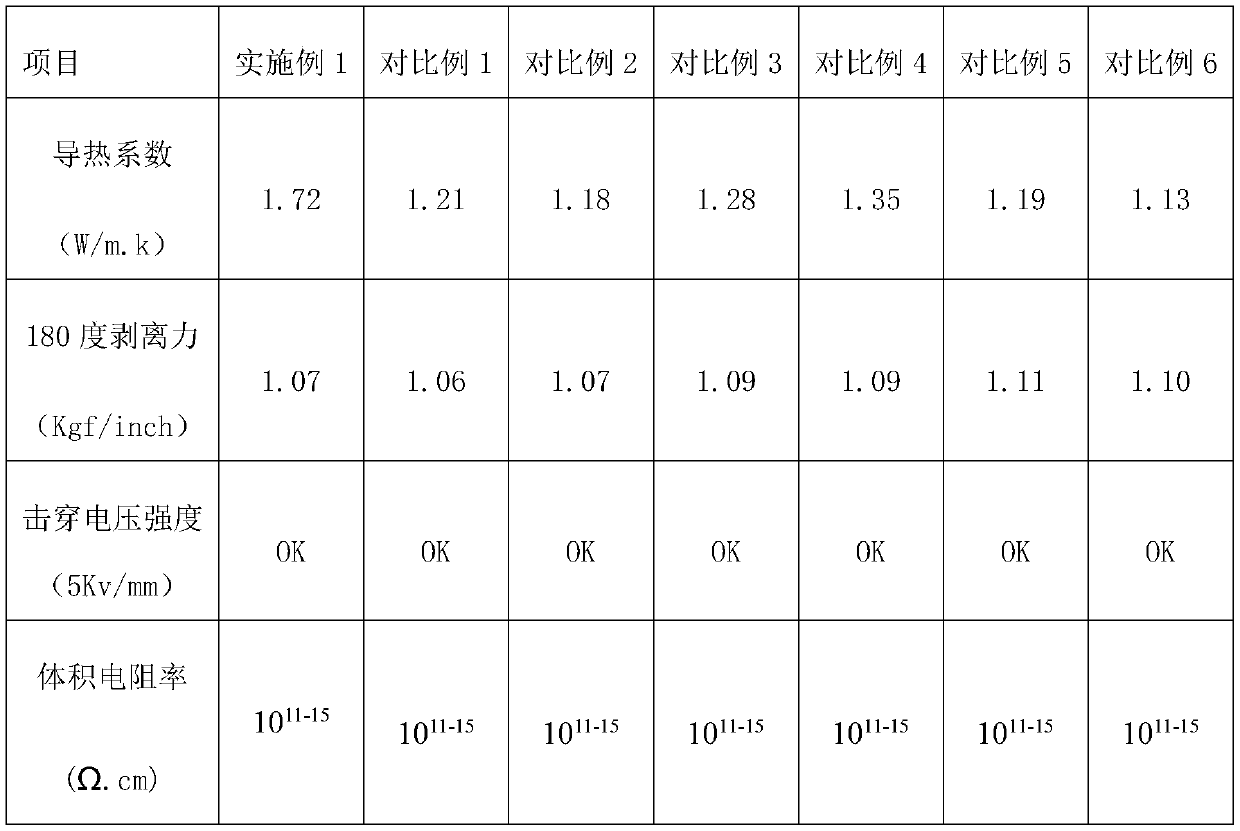

Examples

Embodiment 1

[0021] (1) According to the commercially available flame retardant acrylic adhesive: isocyanate curing agent: epoxy resin curing agent: anhydrous ethyl acetate: aluminum oxide: aluminum hydroxide: boron nitride = 100: 1: 1: 25: 27.5: 12.5: The formula of 4 is used to configure the glue, and the glue is applied according to the different glue amount of 800r / min;

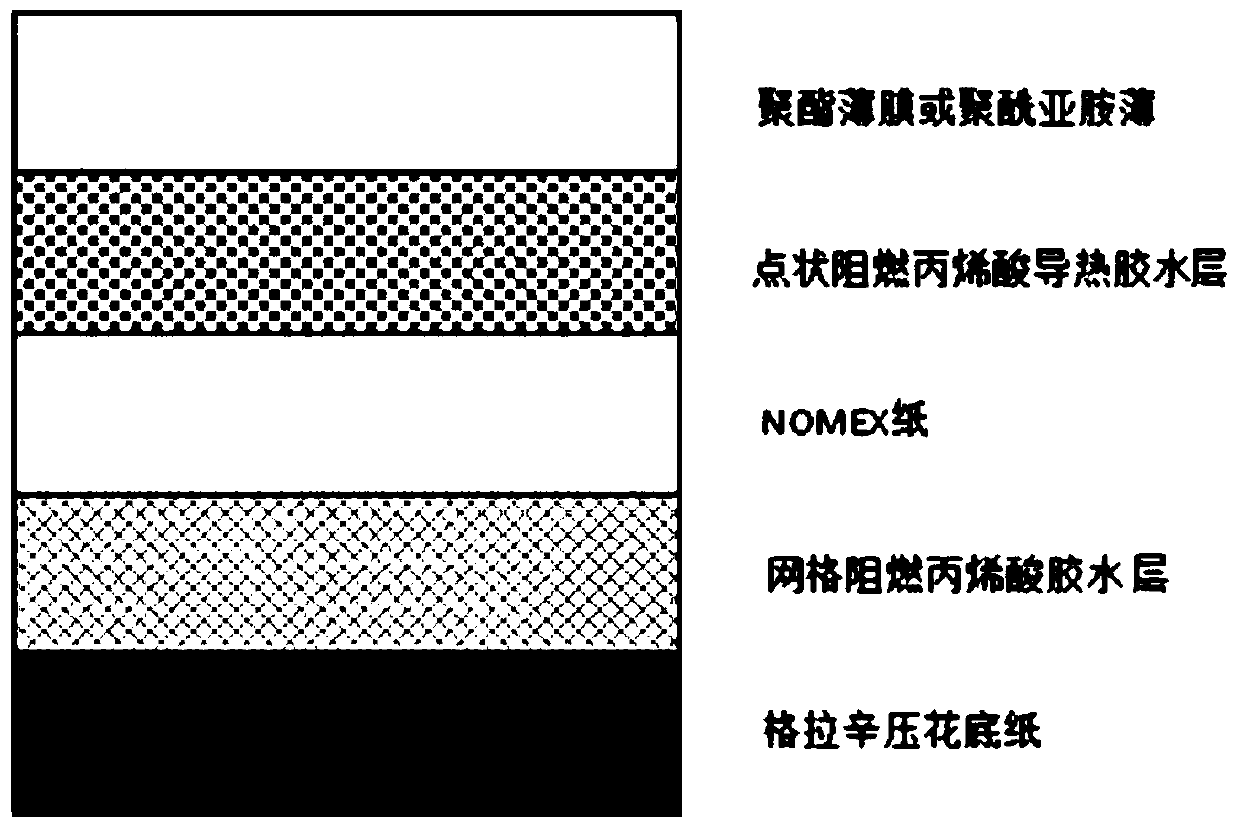

[0022] (2) Apply the configured glue on a commercially available polyester film or polyimide film of 20um in dot shape through a 14-mesh large grid gravure anilox roller. The glue thickness is 10um. After baking in a hot oven Paste 20um commercially available NOMEX paper, this is a semi-finished product;

[0023] (3) Configure the glue according to the formula of commercially available solvent-based flame-retardant acrylic glue: isocyanate curing agent: epoxy resin curing agent: anhydrous ethyl acetate = 100:1:1:25, and glue it at 800r / min;

[0024] (4) Coat the glue on the embossed glassine release film by means of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com