Preparation method of diphenylamine micro-crystal suspension

A technology of diphenylamine and suspension, which is applied in the fields of dyes and agriculture, can solve problems such as the difficulty in preparing diphenylamine solution, and achieve the effects of wide application range, simple preparation method and long storage time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] A kind of preparation method of diphenylamine microcrystalline suspension of the present invention, this preparation method step is as follows:

[0028] a. Add diphenylamine to the high-speed shearing kettle and heat up to 60-80°C to melt the material;

[0029] b. Turn on the high-speed shearing machine and slowly increase the speed to 2000-7000r / min;

[0030] c. Maintain the temperature and rotation speed of the kettle, and slowly add 60-90wt% deionized water;

[0031] d. During the process of adding deionized water, slowly add 0.05-5wt% emulsifier, 0.05-1wt% spreading agent, and 0.01-1wt% defoamer;

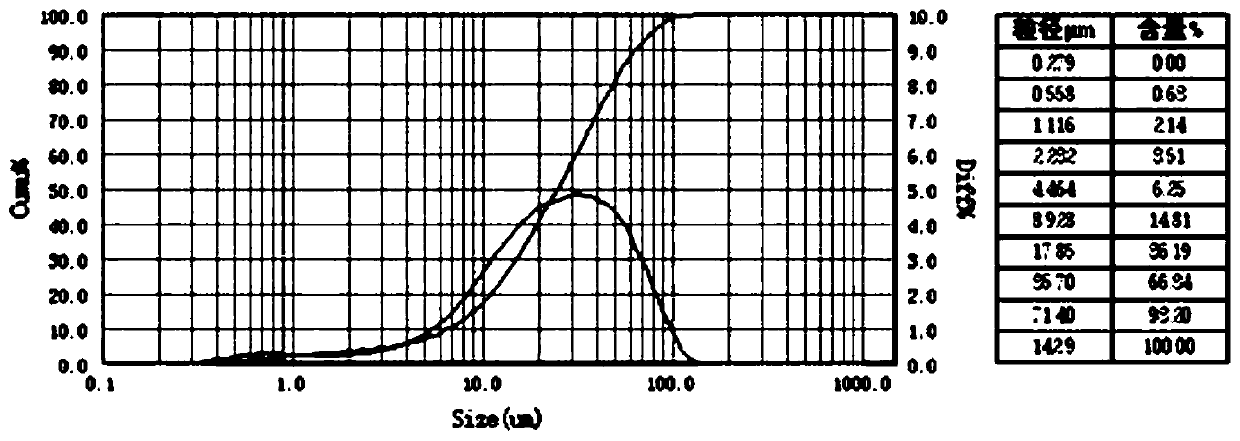

[0032] e. Maintain the shear rate and slowly cool down to 10-20° C. to obtain a diphenylamine microcrystalline suspension with an average particle size of ≤35 μm.

[0033] Wherein, the emulsifier is disproportionated rosinate, dodecylbenzenesulfonate, dodecylsulfate, among which

[0034] Choose lauryl sulfate, the ratio of emulsifier to diphenylamine is 1:3~20.

Embodiment 1

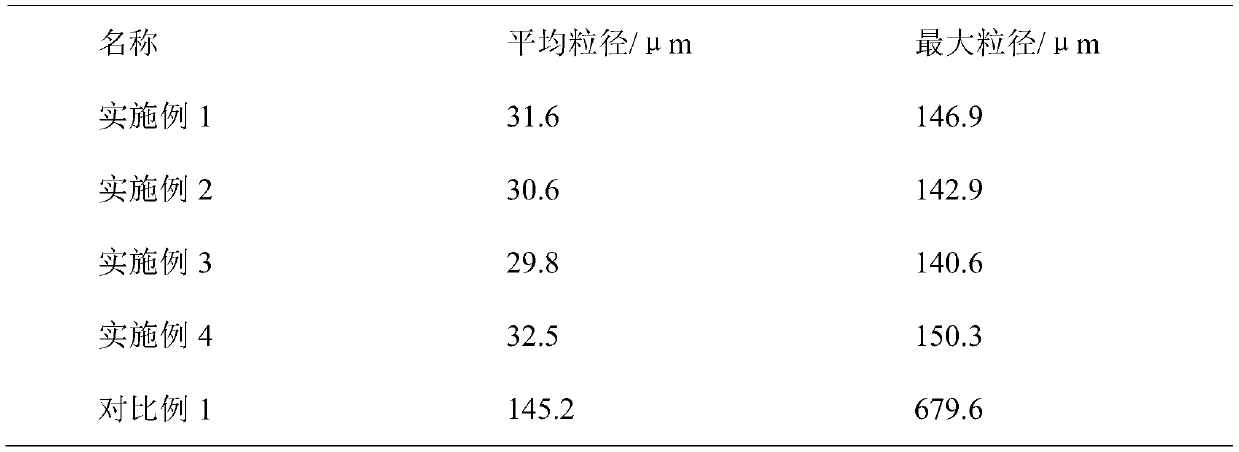

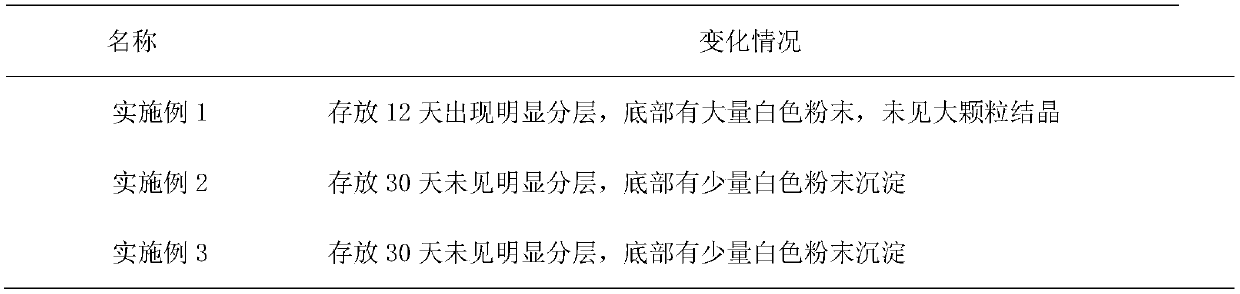

[0036] Weigh 140g of diphenylamine, melt the diphenylamine into a liquid at 60-80°C, and slowly add 250g of deionized water, 8g of sodium dodecylbenzenesulfonate, 1g of Fatty acid sodium, 1g compound organic silicon defoamer and other processing aids form a stable milky white liquid, maintain a high shear rate, slowly cool down to 10-20 ° C, and prepare a suspension of diphenylamine microcrystals with a content of 35%.

Embodiment 2

[0038] Weigh 140g of diphenylamine, melt the diphenylamine into a liquid at 60-80°C, and slowly add 250g of deionized water, 8g of sodium lauryl sulfate, and 1g of sodium fatty acid under the action of a high-speed shearing machine at 2000-7000r / min , 1g compound organic silicon defoamer and other processing aids to form a stable milky white liquid, maintain a high shear rate, slowly cool down to 10-20 ° C, and prepare a suspension of diphenylamine microcrystals with a content of 35%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com