Fire extinguishment system and method in fabrication bin of electrochemical energy storage station based on gas extinguishment and mechanical ventilation and heat dissipation

A mechanical ventilation and fire extinguishing system technology, applied in the field of safety, can solve the problems of endangering containers, poor cooling effect, and increased pressure, and achieve the effects of suppressing flame spray, improving cooling effect, and effective pressure relief

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

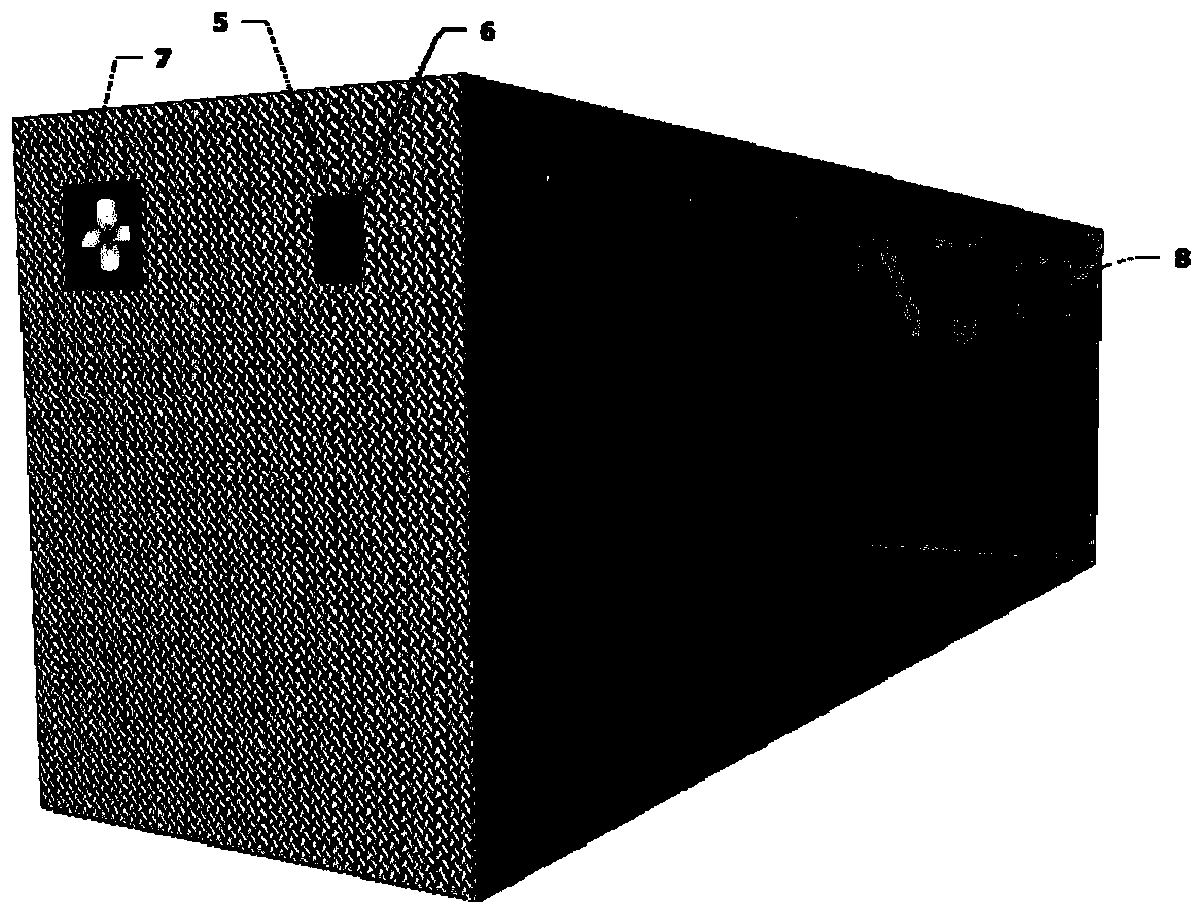

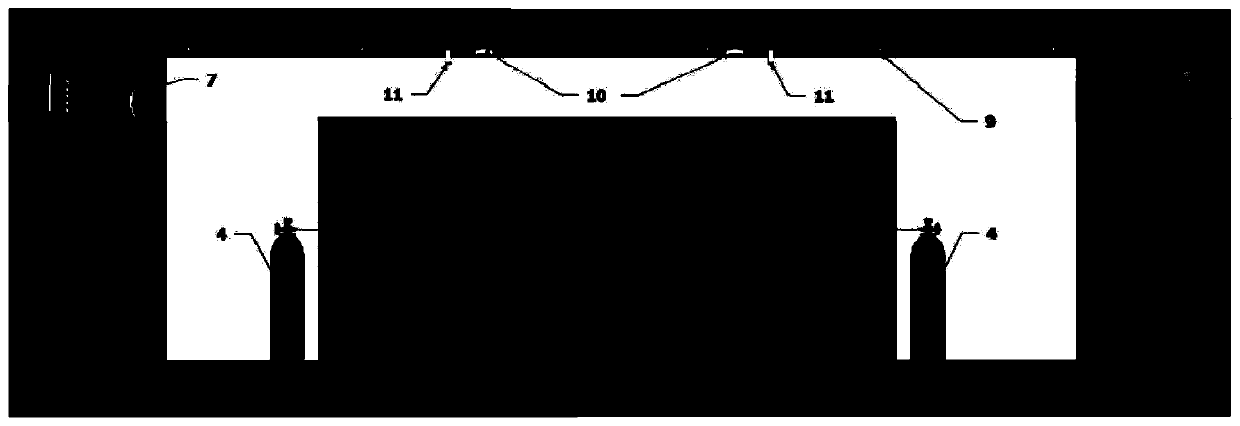

[0026] The fire extinguishing system in the prefabricated cabin of the electrochemical energy storage station mainly includes: a gas automatic fire extinguishing system, a pressure relief system and a mechanical ventilation and heat dissipation system.

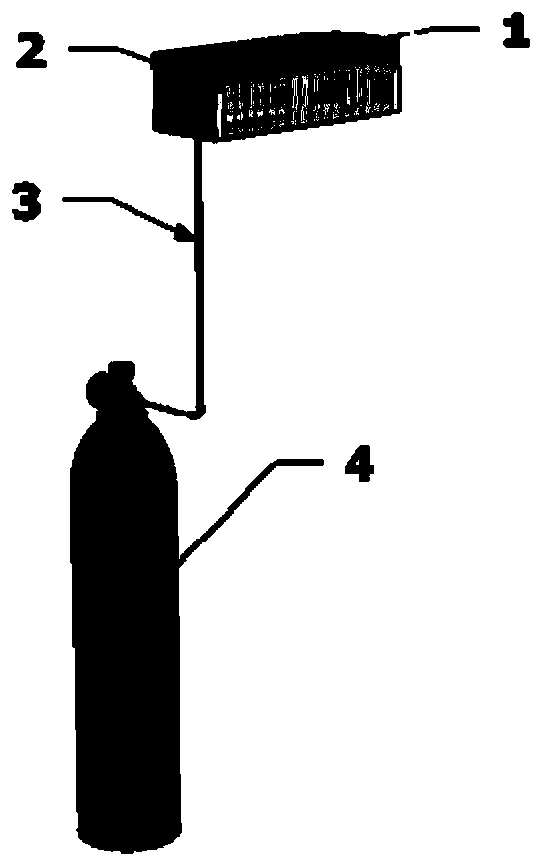

[0027] The gas automatic fire extinguishing system is mainly a fire detection and fire extinguishing system. The fire detector in the system is located 2-3cm above the battery safety valve in the battery module. Its main function is to accurately extinguish the battery fire when the battery in the module is thermally out of control, and extinguish the battery fire in a short time. It mainly includes fire detection tube 1, miniature pressure sensor 2, steel pipeline 3 and storage tank 4 and other parts. If the gas fire extinguishing system fails or fails to extinguish the fire, the water mist n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com