A high-salt and high-cod chemical hazardous waste treatment and resource recovery method

A resourceful and chemical technology, applied in chemical instruments and methods, separation methods, petroleum industry, etc., can solve the problems of restricting the popularization and application of incineration and landfill methods, high project cost, high COD, etc., and avoid catalyst deactivation As well as the effect of safety accidents, small footprint, and reduced operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

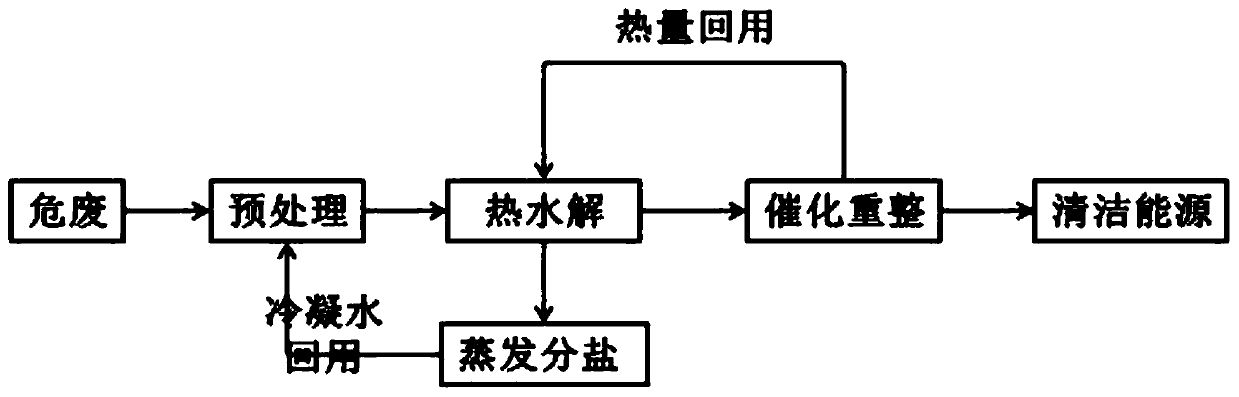

[0026] see figure 1 , a high-salt and high-COD chemical hazardous waste treatment and recycling method, the method comprises the following steps:

[0027] (1) Pretreat the high-salt and high-COD chemical hazardous waste; during the pre-treatment, the high-salt and high-COD chemical hazardous waste is transported to the metering storage tank through the conveying device, and then an appropriate amount of water is added to prepare the material slurry , and preheating and stirring the material slurry; the concentration of the material slurry is 15-35wt%;

[0028] (2) The pretreated material slurry is subjected to thermal hydrolysis treatment to generate high-concentration brine and mixed gas; the thermal hydrolysis treatment is carried out in a thermal hydrolysis reactor, using batch operation or continuous mode operation, in Pressurization and decompression devices are installed before and after the thermal hydrolysis reactor; the thermal hydrolysis treatment is carried out at ...

Embodiment 2

[0037] see figure 1 , a high-salt and high-COD chemical hazardous waste treatment and recycling method, the method comprises the following steps:

[0038] (1) Pretreat the high-salt and high-COD chemical hazardous waste; during the pre-treatment, the high-salt and high-COD chemical hazardous waste is transported to the metering storage tank through the conveying device, and then an appropriate amount of water is added to prepare the material slurry , and preheating and stirring the material slurry; the concentration of the material slurry is 15-35wt%;

[0039] (2) The pretreated material slurry is subjected to thermal hydrolysis treatment to generate high-concentration brine and mixed gas; the thermal hydrolysis treatment is carried out in a thermal hydrolysis reactor, using batch operation or continuous mode operation, in Pressurization and decompression devices are installed before and after the thermal hydrolysis reactor; the thermal hydrolysis treatment is carried out at ...

Embodiment 3

[0048] see figure 1 , a high-salt and high-COD chemical hazardous waste treatment and recycling method, the method comprises the following steps:

[0049] (1) Pretreat the high-salt and high-COD chemical hazardous waste; during the pre-treatment, the high-salt and high-COD chemical hazardous waste is transported to the metering storage tank through the conveying device, and then an appropriate amount of water is added to prepare the material slurry , and preheating and stirring the material slurry; the concentration of the material slurry is 15-35wt%;

[0050] (2) The pretreated material slurry is subjected to thermal hydrolysis treatment to generate high-concentration brine and mixed gas; the thermal hydrolysis treatment is carried out in a thermal hydrolysis reactor, using batch operation or continuous mode operation, in Pressurization and decompression devices are installed before and after the thermal hydrolysis reactor; the thermal hydrolysis treatment is carried out at ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com