780mpa low-carbon low-alloy trip steel and its rapid heat treatment method

A rapid heat treatment and low-alloy technology, applied in heat treatment furnaces, heat treatment equipment, furnaces, etc., can solve the problems of high manufacturing costs and high equipment requirements, and achieve the effects of reducing production costs, energy consumption, and time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0061] The chemical composition of the selected raw material steel is calculated by weight percentage: C-0.16%, Mn-1.6%, Si-1.4%, and the balance is Fe and unavoidable impurity elements. The steel plate before heat treatment is cold-rolled strip steel, and the cold-rolling reduction rate is 65%. The microstructure of steel plate after cold rolling is composed of pearlite and ferrite.

[0062] The heat treatment process steps are as follows:

[0063] 1) Heat the steel plate to 770°C at a heating rate of 300°C / s and keep it warm for 60s;

[0064] 2) Cool the steel plate to 410°C at a cooling rate of 40°C / s and keep it warm for 200s;

[0065] 3) Rapid cooling from 410°C to room temperature at 50°C / s.

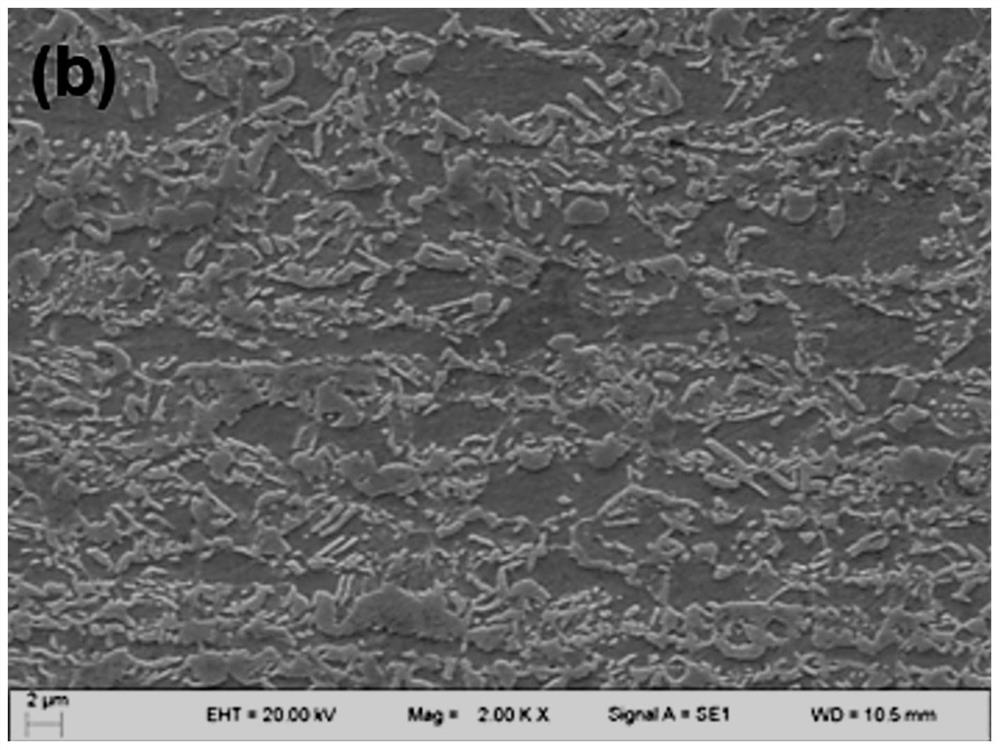

[0066] The whole process of the above heat treatment takes about 278s, and the microstructure of the obtained TRIP steel is as follows: figure 1 As shown, the bainite is obviously refined and is in the submicron granular form; the austenite is distributed in an island shape; and ...

Embodiment 2

[0070] The chemical composition of the selected raw material steel is calculated by weight percentage: C-0.22%, Mn-2.2%, Si-1.2%, and the balance is Fe and unavoidable impurity elements. The steel plate before heat treatment is cold-rolled strip steel, and the cold-rolling reduction rate is 55%. The microstructure of steel plate after cold rolling is composed of pearlite and ferrite.

[0071] The heat treatment process steps are as follows:

[0072] 1) Heat the strip steel plate to 800°C at a heating rate of 30°C / s and keep it warm for 90s;

[0073] 2) Cool the steel plate to 430°C at a cooling rate of 100°C / s and keep it warm for 250s;

[0074] 3) Rapid cooling from 430°C to room temperature at 100°C / s.

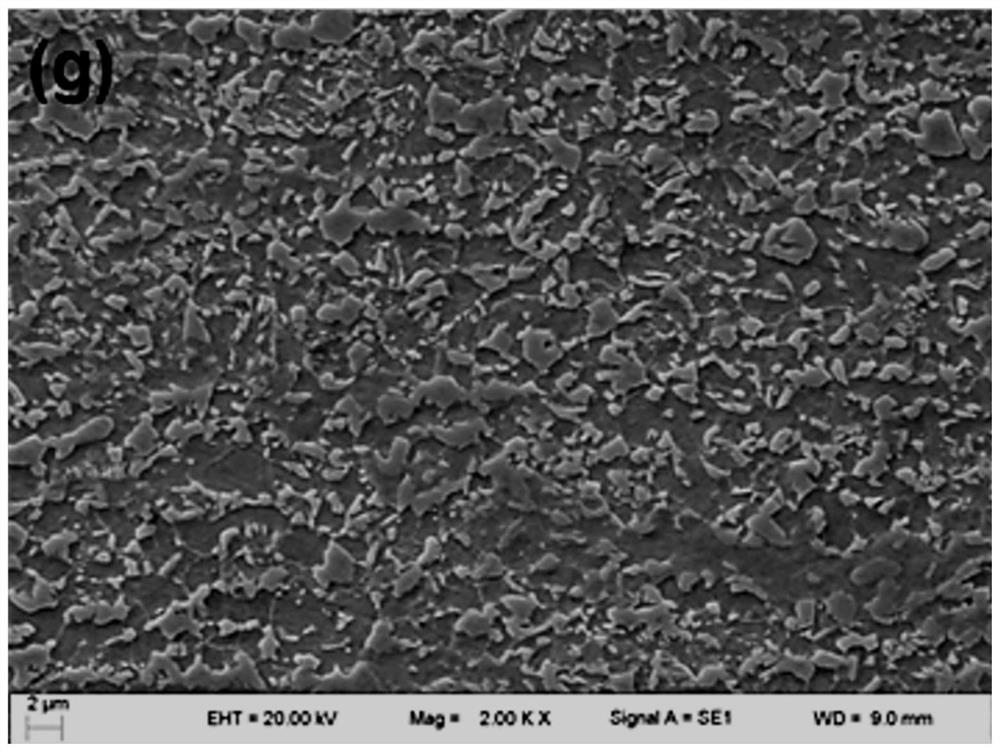

[0075] The whole process of the above heat treatment takes about 374s, and the microstructure of the obtained TRIP steel is as follows: image 3 As shown, the bainite particle size is very small; the austenite is distributed in an island shape; the bainite and austenite ...

Embodiment 3

[0079] The chemical composition of the selected raw material steel is calculated by weight percentage: C-0.18%, Mn-2.0%, Si-1.6%, and the balance is Fe and unavoidable impurity elements. The steel plate before heat treatment is cold-rolled strip steel, and the cold-rolling reduction rate is 65%. The microstructure of steel plate after cold rolling is composed of pearlite and ferrite.

[0080] The heat treatment process steps are as follows:

[0081] 1) Heat the steel plate to 850°C at a heating rate of 200°C / s and keep it warm for 40s;

[0082] 2) Cool the steel plate to 420°C at a cooling rate of 80°C / s and keep it warm for 300s;

[0083] 3) Rapid cooling from 420°C to room temperature at 150°C / s.

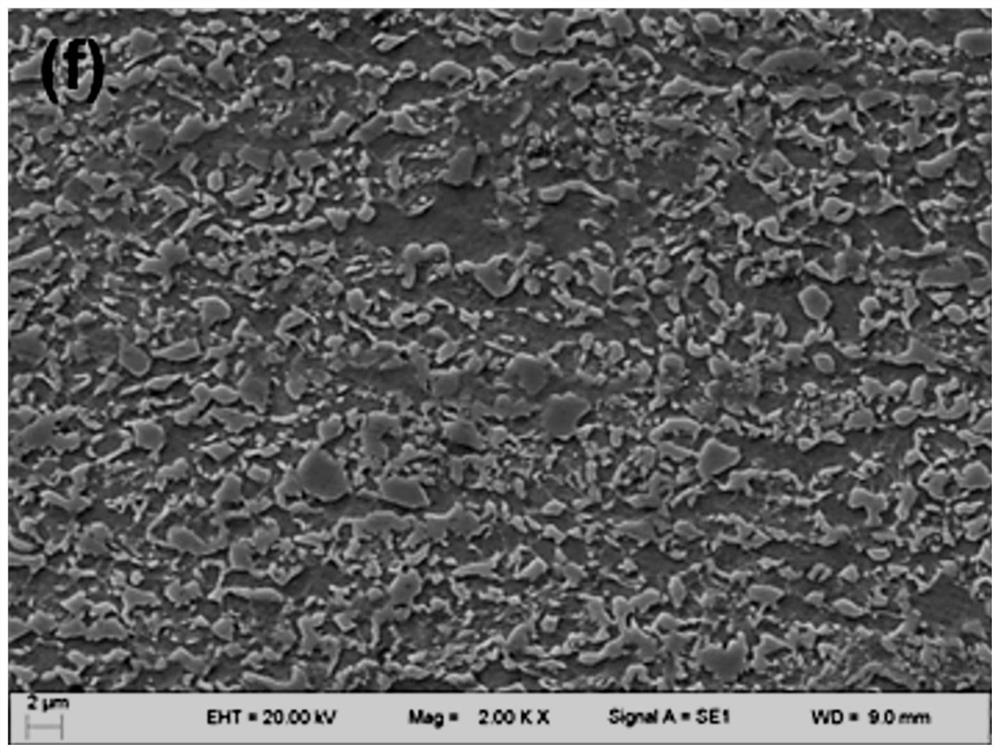

[0084] The whole process of the above heat treatment takes about 352s, and the microstructure of the obtained TRIP steel is as follows: Figure 5 As shown, the size of bainite is obviously smaller; the austenite is distributed in an island shape; the bainite and austenite are ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com