A kind of low-temperature curing method of silver-coated silica gel

A curing method, silver silica gel technology, applied in the direction of radioactive purification, nuclear engineering, etc., can solve the problems of unsatisfactory long-term disposal of radioactive iodine, the deformation of the solidified body affects stability, etc., and achieve good industrial application prospects, low iodine leaching rate, thermal The effect of low release rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0066] In this example, the common iodine-127 is used to simulate the radionuclide iodine-129. A low-temperature curing method for silver-coated silica gel, comprising the following steps:

[0067] (1) 9.778g silica gel, 2.223gAgI, 4.581gSiO 2 , 11.359gB 2 o 3 , 8.472gBi 2 o 3 , 5.587g ZnO was added with deionized water and placed in a colloid mill to fully grind for 24 hours, evaporated and dried at 100°C for 6 hours to obtain a dry mixture;

[0068] (2) the dry mixture is pre-pressed at 10MPa to obtain a block-like dry mixture;

[0069] (3) Put the block-shaped dry mixture into a high-temperature muffle furnace, raise the temperature from room temperature to 550°C, keep it at 550°C for 6 hours, then cool it down to 200°C at a cooling rate of 1°C / min, and then cool it naturally to room temperature , to obtain a borate glass ceramic sintered body containing iodine-coated silver silica gel.

[0070] After the sample was taken out, the bulk density of the borate glass cer...

Embodiment 2

[0072] In this example, the common iodine-127 is used to simulate the radionuclide iodine-129. A low-temperature curing method for silver-coated silica gel, comprising the following steps:

[0073] (1) 0.518g silica gel, 1.482gAgI, 2.376gSiO 2 , 0.597gB 2 o 3 , 3.029gBi 2 o 3 , 1.998g ZnO was added to deionized water and placed in a colloid mill to grind for 28 hours, evaporated and dried at 100°C for 6 hours to obtain a dry mixture;

[0074] (2) the dry mixture is pre-pressed at 15MPa to obtain a block-like dry mixture;

[0075] (3) Put the block-shaped dry mixture into a high-temperature muffle furnace, raise the temperature from room temperature to 550°C, keep it at 550°C for 6 hours, then cool it down to 200°C at a cooling rate of 2°C / min, and then cool it naturally to room temperature , to obtain a borate glass ceramic sintered body containing iodine-coated silver silica gel.

[0076] After the sample was taken out, the bulk density of the borate glass ceramic sint...

Embodiment 3

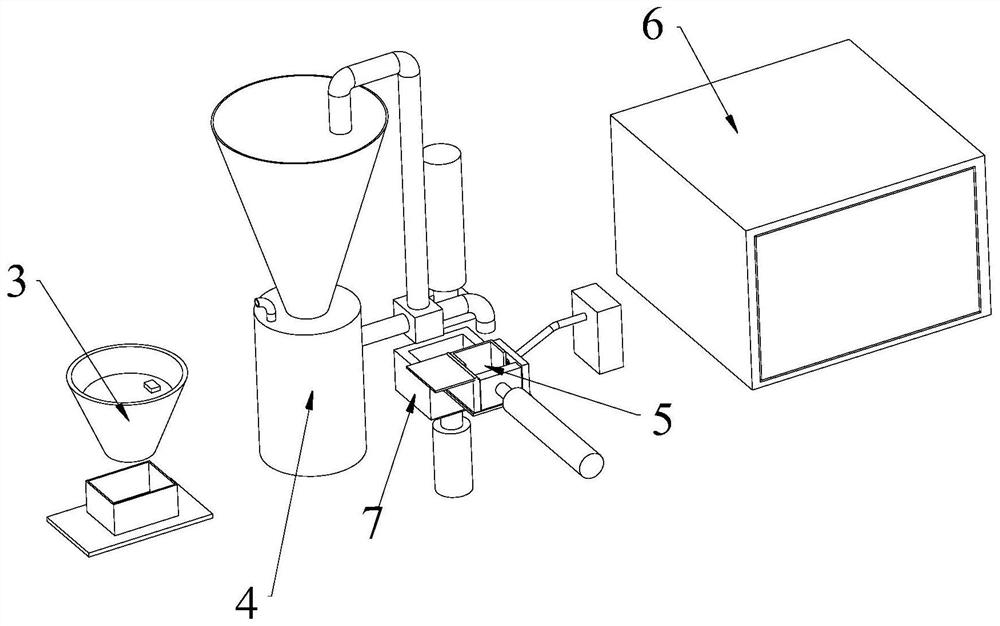

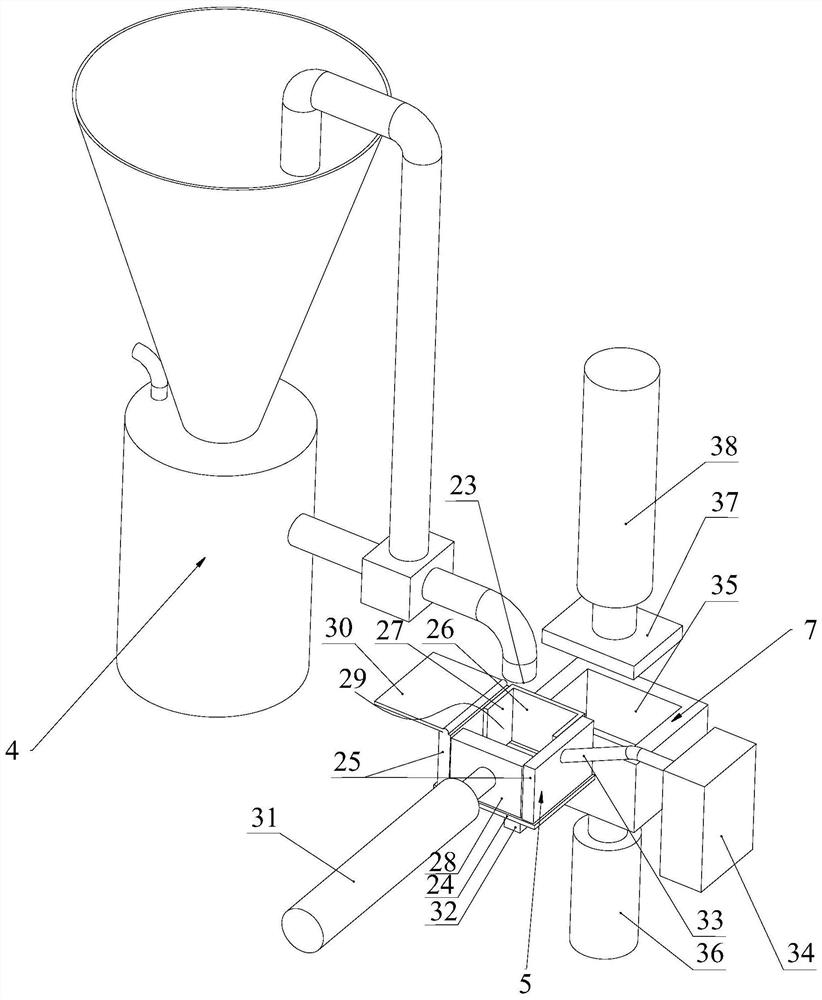

[0084] Such as figure 1 As shown, this embodiment discloses a curing device for implementing the method of the present application, and the curing device includes:

[0085] Silver-coated silica gel particle filter mechanism 3;

[0086] Colloid mill 4, used for mixing and grinding silver-coated silica gel particles and solidified substrate raw material powder;

[0087] Drying device 5, is used for receiving the wet mixture from colloid mill 4, and to mixture drying, obtains dry mixture;

[0088] The second sintering device 6 is used for sintering the dried mixture.

[0089] The second sintering device 6 may be equipment such as a high-temperature muffle furnace or a microwave sintering furnace.

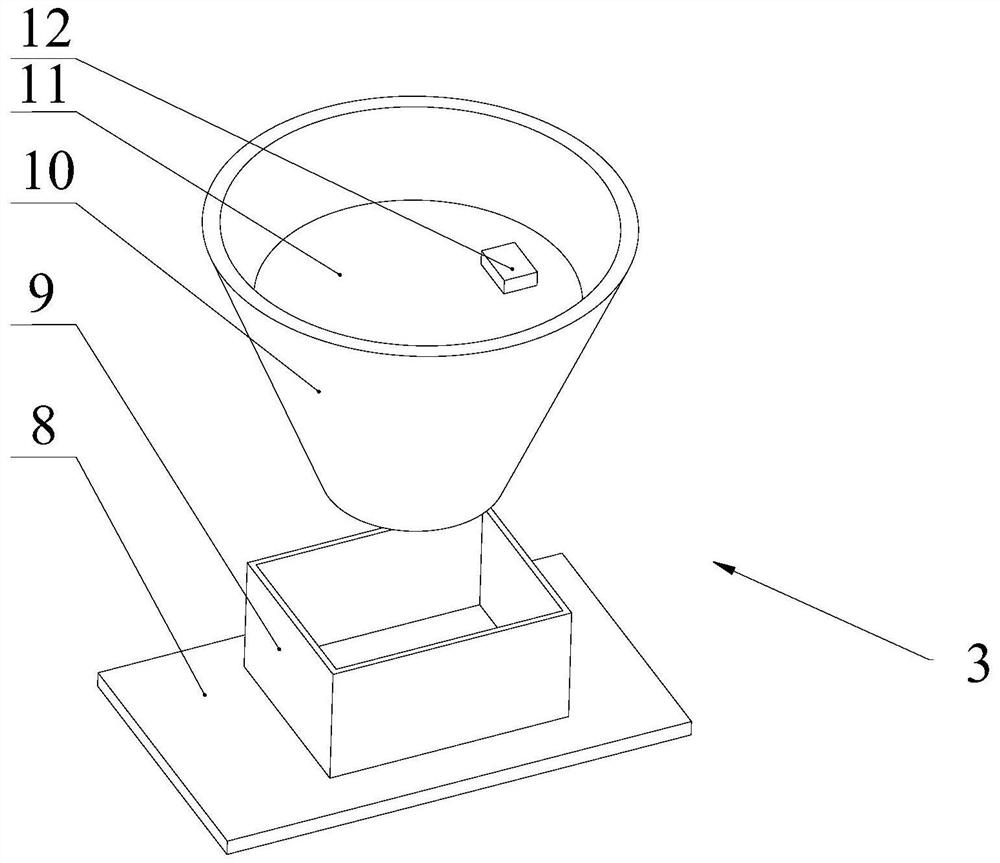

[0090] Such as figure 2 As shown, the silver-coated silica gel particle filter mechanism 3 includes:

[0091] weighing scale 8;

[0092] The first funnel 10 is arranged directly above the weighing scale 8;

[0093] Filter screen 11 is installed in the first funnel 10;

[0094]...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Loading capacity | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com