Coaxial laser with wavelength calibration and light source core thereof

A technology of coaxial lasers and lasers, which is applied to lasers, laser components, semiconductor lasers, etc., can solve the problems of lasers not being able to self-calibrate their wavelength, poor wavelength stability, and poor self-calibration control accuracy, and achieve high temperature stability. Large thermal inertia, reducing the effect of temperature control time delay

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

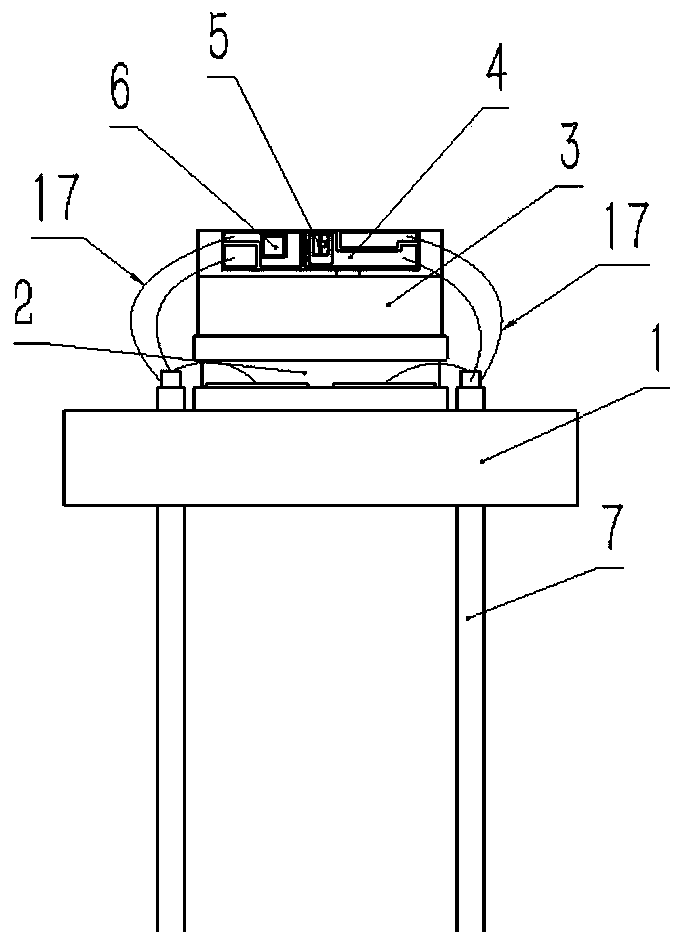

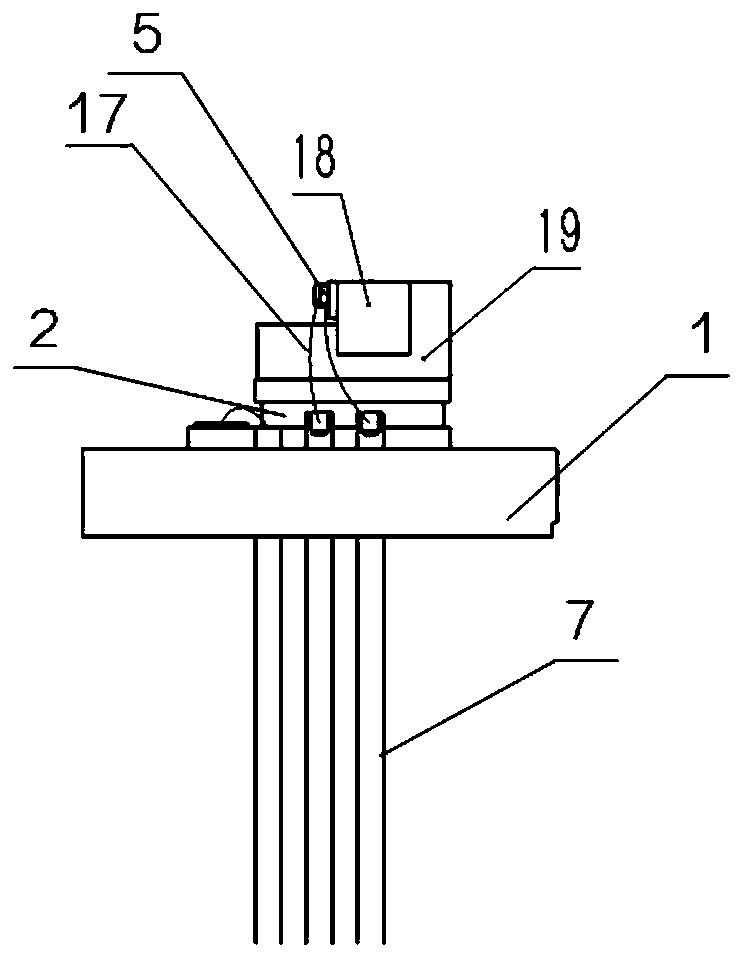

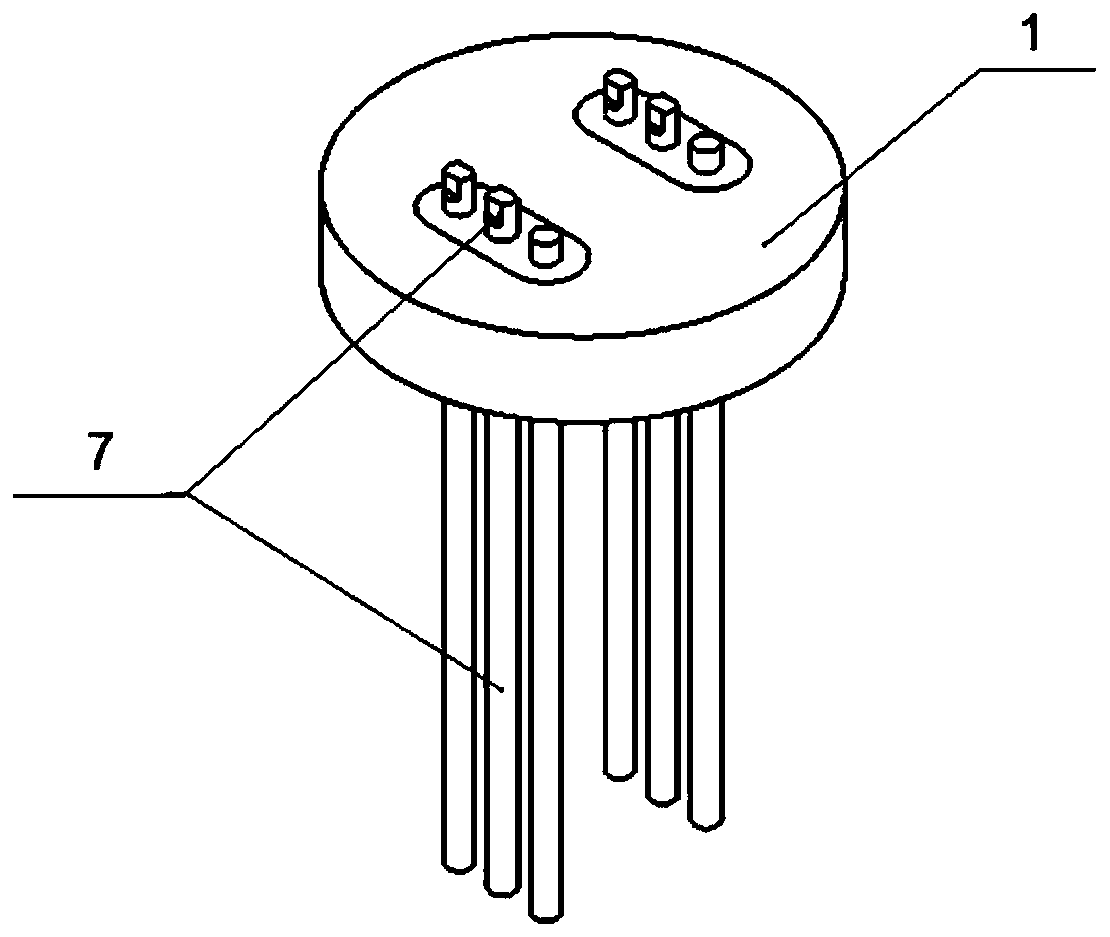

[0051] Embodiment one, as Picture 1-1 and Figure 1-2 As shown, a coaxial laser light source core with its own wavelength calibration includes a TO tube base 1, a TEC cooler 2 arranged on the upper surface of the TO tube base 1, and a heat conduction heat transfer device arranged on the upper surface of the TEC cooler 2. The spacer 3, the aluminum nitride spacer 4 arranged on the upper surface of the heat conduction spacer 3, and the laser chip 5 and the thermistor 6 respectively arranged on the upper surface of the aluminum nitride spacer 4;

[0052] It also includes a TO pin 7 that is provided through the TO tube socket, and the TEC cooler 2, the laser chip 5 and the thermistor 6 are all electrically connected to the TO pin 7, and the The main optical axis of the laser chip 4 is coaxial with the central axis of the TO socket 1;

[0053] The TEC refrigerator 2 includes a temperature-controlling cold surface and a heat-dissipating heat surface, the upper surface of the TEC r...

Embodiment 2

[0070] Embodiment two, such as Figure 4 As shown, a coaxial laser with its own wavelength calibration includes a coaxial laser source core 10 in the present invention, and also includes a tube body 11, and the coaxial laser source core 10 is fixedly welded on the tube body 11 One end inside and the TO pin 7 extends out of the tube body 11;

[0071] It also includes a coupling lens 12, an optical isolator 13, and a half-reflective sheet 14 that are fixedly welded inside the tube body 11, and the coupling lens 12, the optical isolator 13, and the half-reflective sheet 14 are sequentially coupled with the optical path of the coaxial laser source core 10, the main optical axis of the optical isolator 13 and the coupling lens 12 is coaxial with the central axis of the coaxial laser source core 10, and the semi-transparent The semi-reflective sheet 14 forms an angle of 45° with the central axis of the coaxial laser light source core 10;

[0072] Also includes a photodetector 15 w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com