Barium strontium titanate-lead titanate pyroelectric ceramic and preparation method thereof

A technology of pyroelectric ceramics and barium strontium titanate, which is applied in the field of pyroelectric ceramics to achieve the effects of low production cost, easy chemical composition, and uniform composition of sintered materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

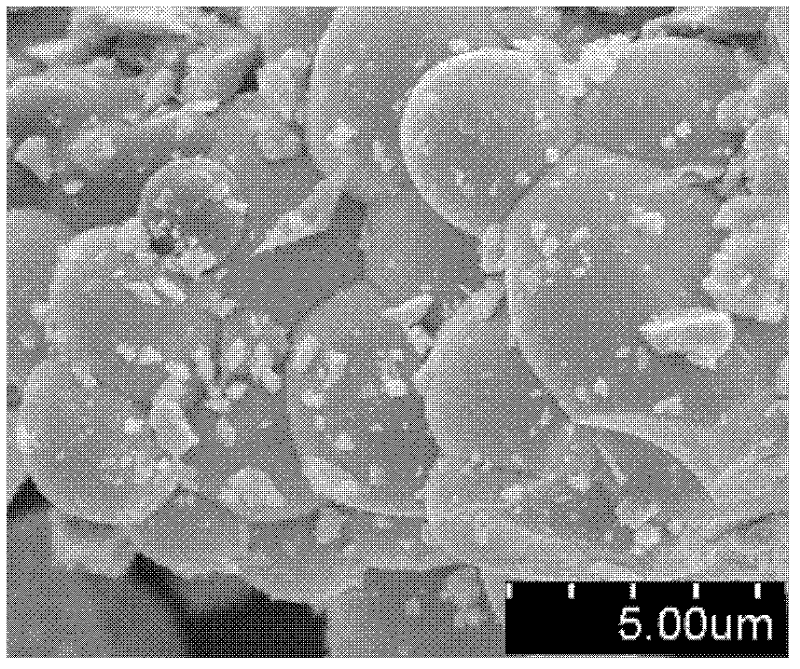

Image

Examples

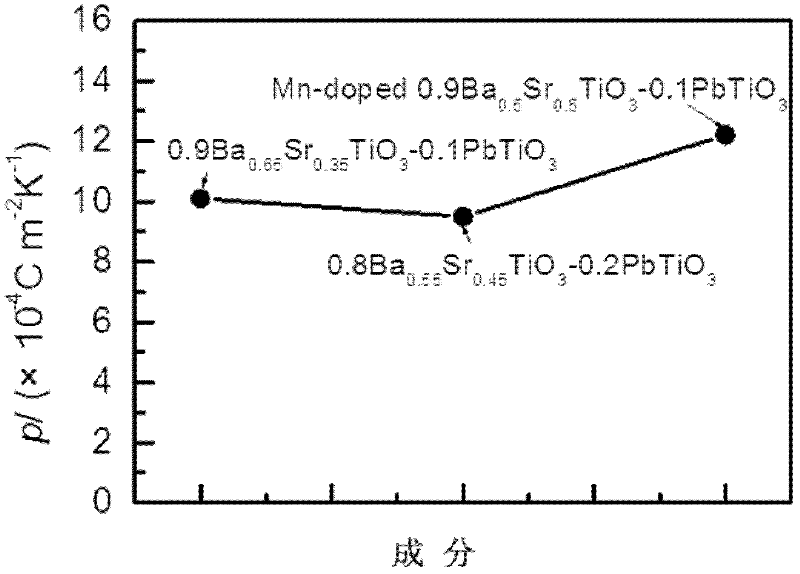

Embodiment 1

[0018] Barium strontium titanate-lead titanate binary ceramics (0.9Ba 0.65 Sr 0.35 TiO 3 -0.1PbTiO 3 ) The composition formula is: Ba 0.65 Sr 0.35 TiO 3 : 90atm%, PbTiO 3 : 10atm%, the process of preparing single-component pyroelectric ceramic materials from the binary system of the above composition formula is as follows:

[0019] (1) weigh lead nitrate, barium nitrate and strontium nitrate by the above-mentioned chemical formula ratio, be dissolved in deionized water at normal temperature, then add the citric acid that is 1: 2 with the metal ion mol ratio to obtain a mixed solution; The chemical formula is to weigh butyl titanate and dissolve it in ethylene glycol to obtain a butyl titanate solution; mix the above mixed solution with the butyl titanate solution, stir for 1 hour, and then adjust its pH to 7-9 with dilute nitric acid. , to obtain a barium strontium titanate-lead titanate precursor solution; put the barium strontium titanate-lead titanate precursor solut...

Embodiment 2

[0027] Barium strontium titanate-lead titanate ceramics (0.8Ba 0.55 Sr 0.45 TiO 3 -0.2PbTiO 3 ) The composition formula is: Ba 0.55 Sr 0.45 TiO 3 : 80 atm%, PbTiO 3 : 20 atm%, the process of preparing single-component pyroelectric ceramic materials from the binary system of the above composition formula is as follows:

[0028] (1) weigh lead nitrate, barium nitrate and strontium nitrate by the above-mentioned chemical formula ratio, be dissolved in deionized water at normal temperature, then add the citric acid that is 1: 2 with the metal ion mol ratio to obtain a mixed solution; The chemical formula is to weigh butyl titanate and dissolve it in ethylene glycol to obtain a butyl titanate solution; mix the above mixed solution with the butyl titanate solution, stir for 2 hours, and then adjust its pH to 7-9 with dilute nitric acid. , to obtain the barium strontium titanate-lead titanate precursor solution; put the barium strontium titanate-lead titanate precursor solutio...

Embodiment 3

[0034] Mn-doped barium strontium titanate-lead titanate (Mn-doped 0.9Ba 0.5 Sr 0.5 TiO 3 -0.1PbTiO 3 ) ceramic composition formula is: Ba 0.5 Sr 0.5 TiO 3 : 90atm%, PbTiO 3 : 10atm%, externally doped with Mn (NO 3 ) 2 Molarity 2 atm%. The process of preparing the single-component pyroelectric ceramic material from the binary system of the above composition formula is as follows:

[0035] (1) weigh lead nitrate, barium nitrate and strontium nitrate by the above-mentioned chemical formula ratio, be dissolved in deionized water at normal temperature, then add the citric acid that is 1: 2 with the metal ion mol ratio to obtain a mixed solution; The chemical formula is to weigh butyl titanate and dissolve it in ethylene glycol to obtain a butyl titanate solution; mix the above mixed solution with the butyl titanate solution, stir for 1 hour, and then adjust its pH to 7-9 with dilute nitric acid. , to obtain the barium strontium titanate-lead titanate precursor solution; p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Curie point | aaaaa | aaaaa |

| relative permittivity | aaaaa | aaaaa |

| Curie point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com