Automatic ingoting control system for vacuum electron beam furnace and control method of automatic ingoting control system

A technology of vacuum electron beam and control system, which is applied in the field of automatic ingot casting control of vacuum melting, can solve the problems that the smooth performance of the outer surface of the metal ingot cannot be guaranteed, the service life of the crucible is shortened, the inner wall of the crucible is worn, and the like, and the outer surface is smooth and the casting is smooth. Low cost of ingots and the effect of avoiding potential safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

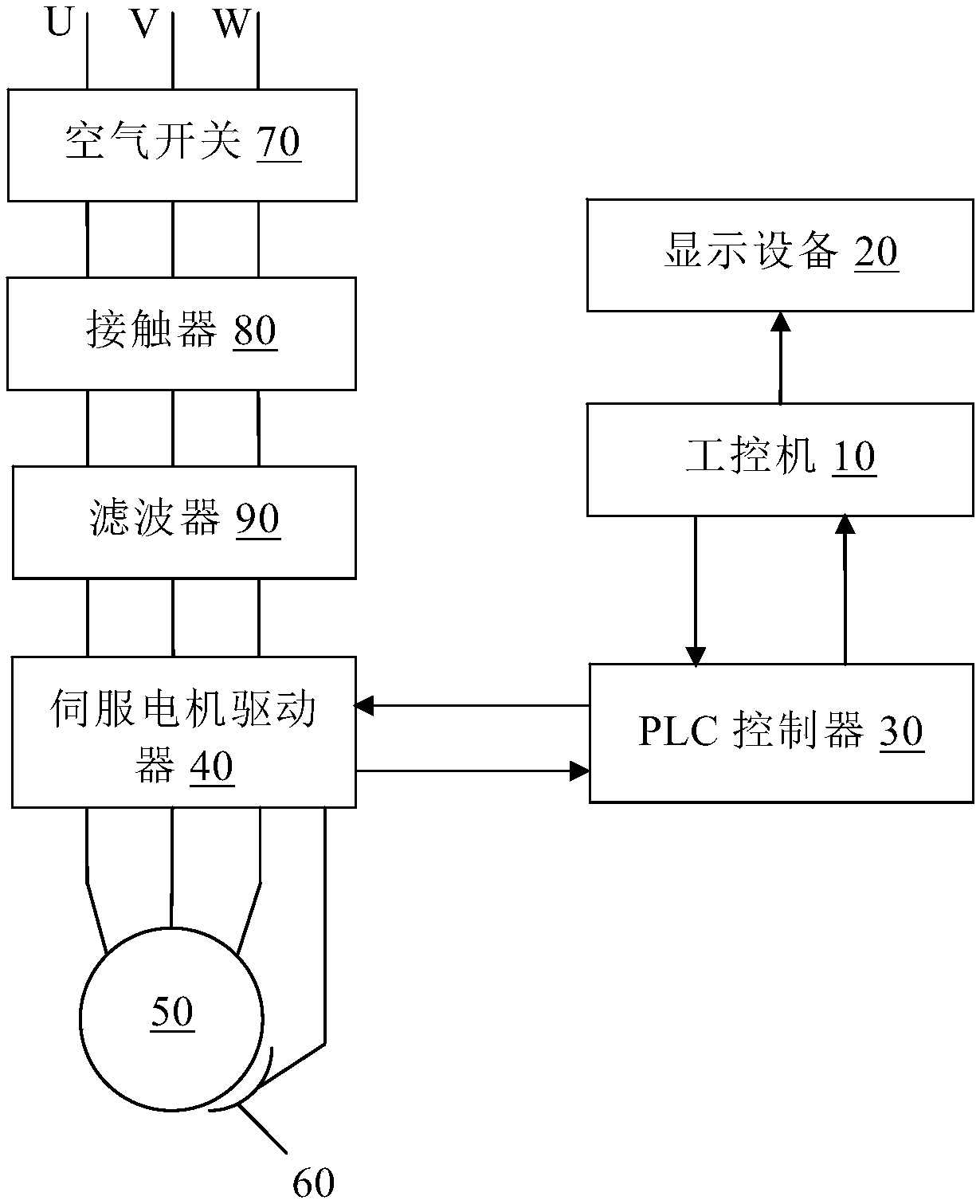

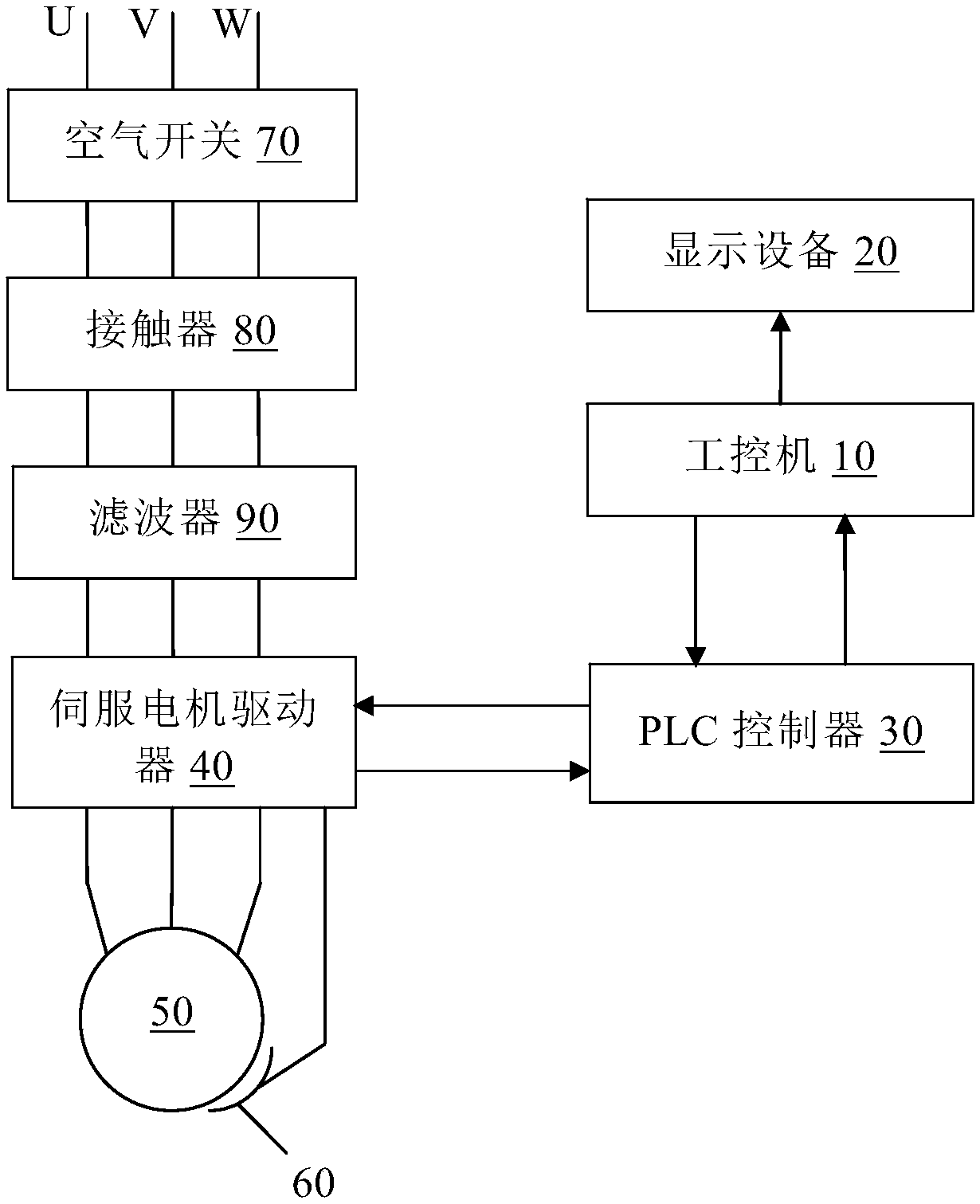

[0014] Such as figure 1 As shown, the automatic ingot casting control system for a vacuum electron beam furnace of the present invention is used in an electron beam furnace for electron beam smelting of metal materials in a vacuum environment, and it includes an industrial computer 10, a PLC controller 30, a servo motor driver 40, an ingot The motor 50, the communication port of the industrial computer 10 is connected with the communication port of the PLC controller 30 through the industrial Ethernet bus, the servo control communication port of the PLC controller 30 is connected with the communication port of the servo motor driver 40 through the industrial Ethernet bus, and the servo motor The motor power input port of the driver 40 is connected to the three-phase power grid through the filter 90, the contactor 80, and the air switch 70. The phase interface is connected to the output port of the motor power supply of the servo motor driver 40, and the three-phase power grid ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com