Lead zirconate titanate-manganese bismuth based perovskite-lead based composite perovskite multi-component low-temperature sintered large-power piezoelectric ceramic, and preparation method thereof

A technology of compounding perovskite and lead zirconate titanate is applied in the field of piezoelectric ceramics and its preparation, and achieves the effects of excellent piezoelectric properties, optimized electrical properties and high mechanical quality factor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Carry out each step successively according to the above-mentioned embodiment mode, the present embodiment adopts the composition general formula of piezoelectric ceramics to be:

[0030] 0.9Pb(Zr 0.48 Ti 0.52 )O 3 +0.04Bi(Mn 2 / 3 Sb 1 / 3 )O 3 +0.06Pb(Mg 1 / 3 Nb 2 / 3 )O 3 . The calcination temperature is 850° C. and the time is 2 hours. The wet ball milling time in deionized water was 10 hours. After compression molding, the green body is sintered at a temperature of 1120° C. for 2 hours. After the two ends of the polished ceramic blank are covered with silver electrodes, place them in 150°C silicone oil and apply a polarizing DC voltage of 4kV / mm, and keep them warm for 15 minutes to obtain high-power piezoelectric ceramics.

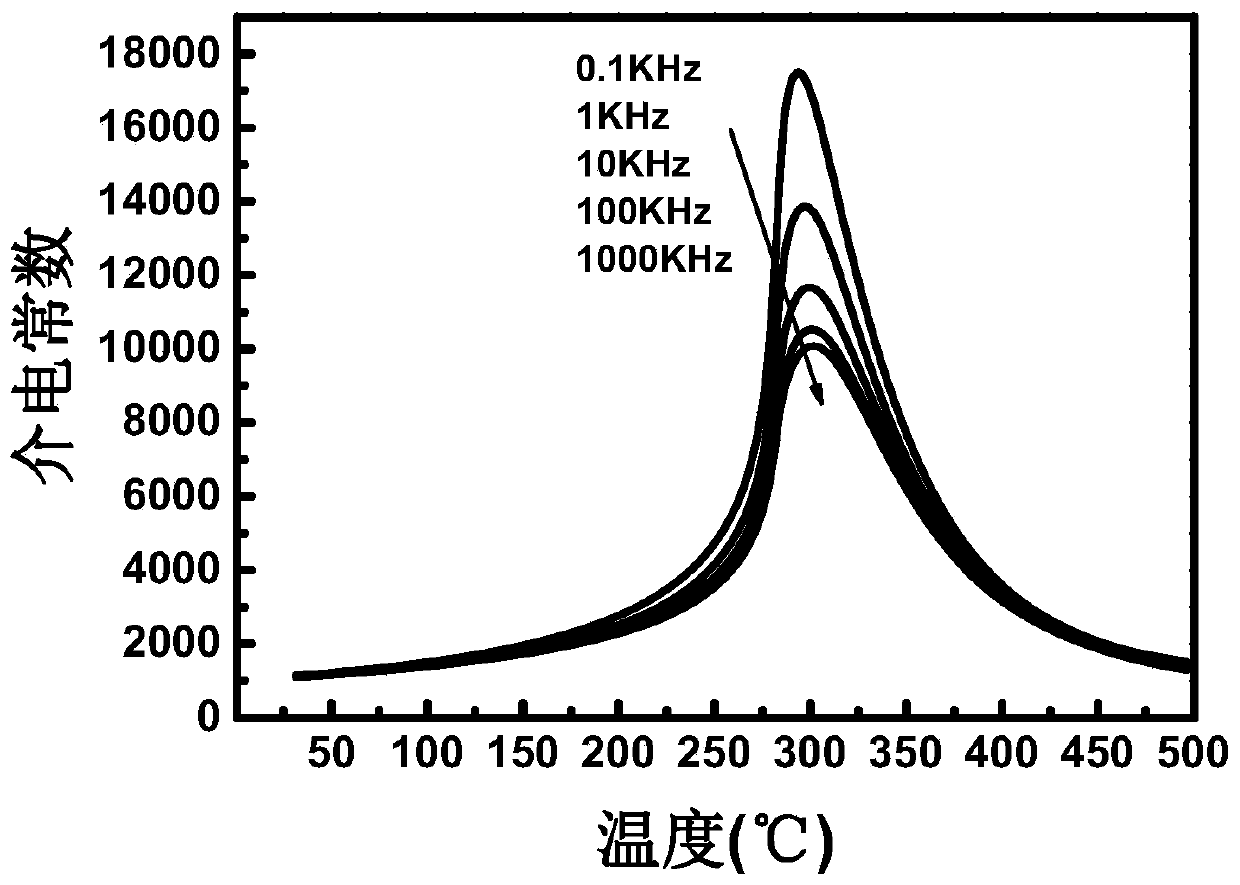

[0031] The dielectric-temperature characteristic curve of the piezoelectric ceramic prepared in this embodiment is as follows figure 1 As shown, other physical properties of the measured sample: the Curie temperature is 296°C, the dielectr...

Embodiment 2

[0033] Carry out each step sequentially according to the above-mentioned embodiment mode, the general composition formula of the piezoelectric ceramic of the present embodiment is:

[0034] 0.8937Pb(Zr 0.48 Ti 0.52 )O 3 +0.03972Bi(Mn 2 / 3 Sb 1 / 3 )O 3 +0.05958Pb(Ni 1 / 3 Nb 2 / 3 )O 3 +0.007Sm 2 o 3 . The calcination temperature is 850° C. and the time is 2 hours. The wet ball milling time in deionized water was 10 hours. After compression molding, the green body is sintered at a temperature of 1020° C. for 2 hours. After the two ends of the polished ceramic blank are covered with silver electrodes, place them in 150°C silicone oil and apply a polarizing DC voltage of 4kV / mm, and keep them warm for 15 minutes to obtain high-power piezoelectric ceramics.

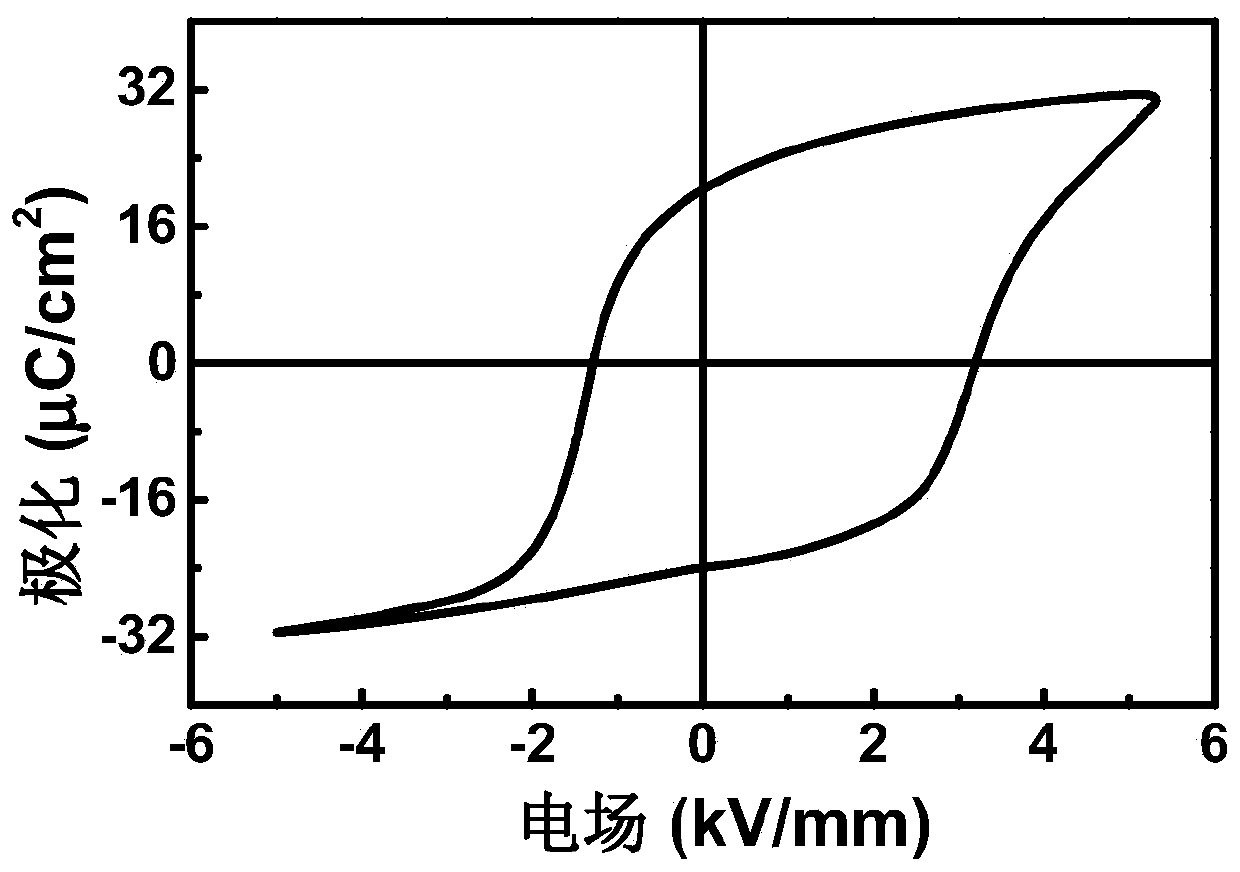

[0035] The piezoelectric ceramic hysteresis loop prepared in this embodiment is as follows figure 2 As shown, its physical properties are: the Curie temperature is 302°C, the dielectric constant is 1620 (1kHz), the p...

Embodiment 3

[0037] Carry out each step sequentially according to the above-mentioned embodiment mode, the general composition formula of the piezoelectric ceramic of the present embodiment is:

[0038] 0.8928Pb(Zr 0.505 Ti 0.495 )O 3 +0.03968Bi(Mn 1 / 2 Ti 1 / 2 )O 3 +0.05952Pb(Zn 1 / 3 Nb 2 / 3 )O 3 +0.004CuO+0.004Fe 2 o 3 . The calcination temperature is 850° C. and the time is 2 hours. The wet ball milling time in deionized water was 10 hours. After compression molding, the green body is sintered at a temperature of 1020° C. for 2 hours. After the two ends of the polished ceramic blank are covered with silver electrodes, place them in 150°C silicone oil and apply a polarizing DC voltage of 4kV / mm, and keep them warm for 15 minutes to obtain high-power piezoelectric ceramics.

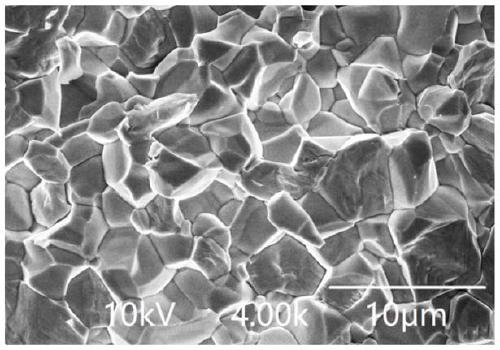

[0039] The scanning electron micrograph of the piezoelectric ceramic section prepared in this embodiment is as follows image 3 As shown, its physical properties are: the Curie temperature is 323°C, the die...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Curie temperature | aaaaa | aaaaa |

| Piezoelectric constant | aaaaa | aaaaa |

| Curie temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap