Plasma jet graphene transparent conductive film substrate preprocessing method

A technology of transparent conductive film and graphene, which is applied to the conductive layer, circuit, and electrical components on the insulating carrier, can solve the problems of high efficiency, low cost, and low process requirements, and achieve high efficiency, convenient operation, and simple implementation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

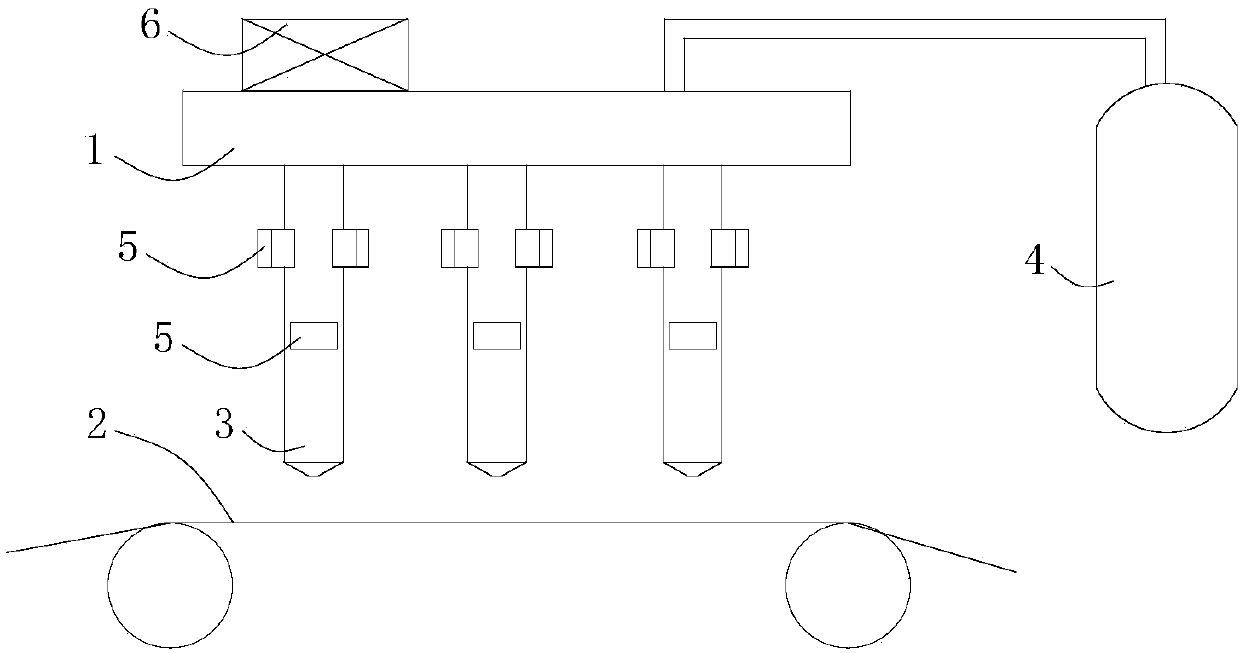

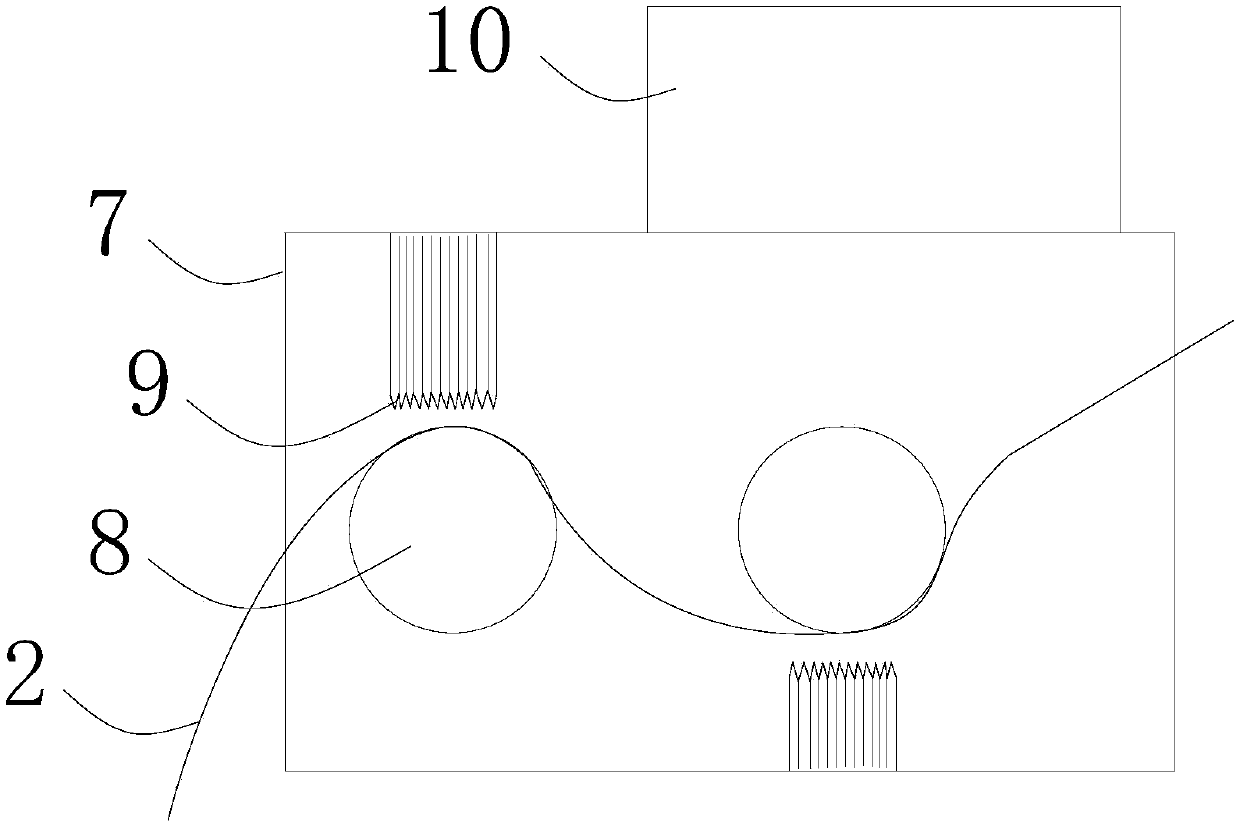

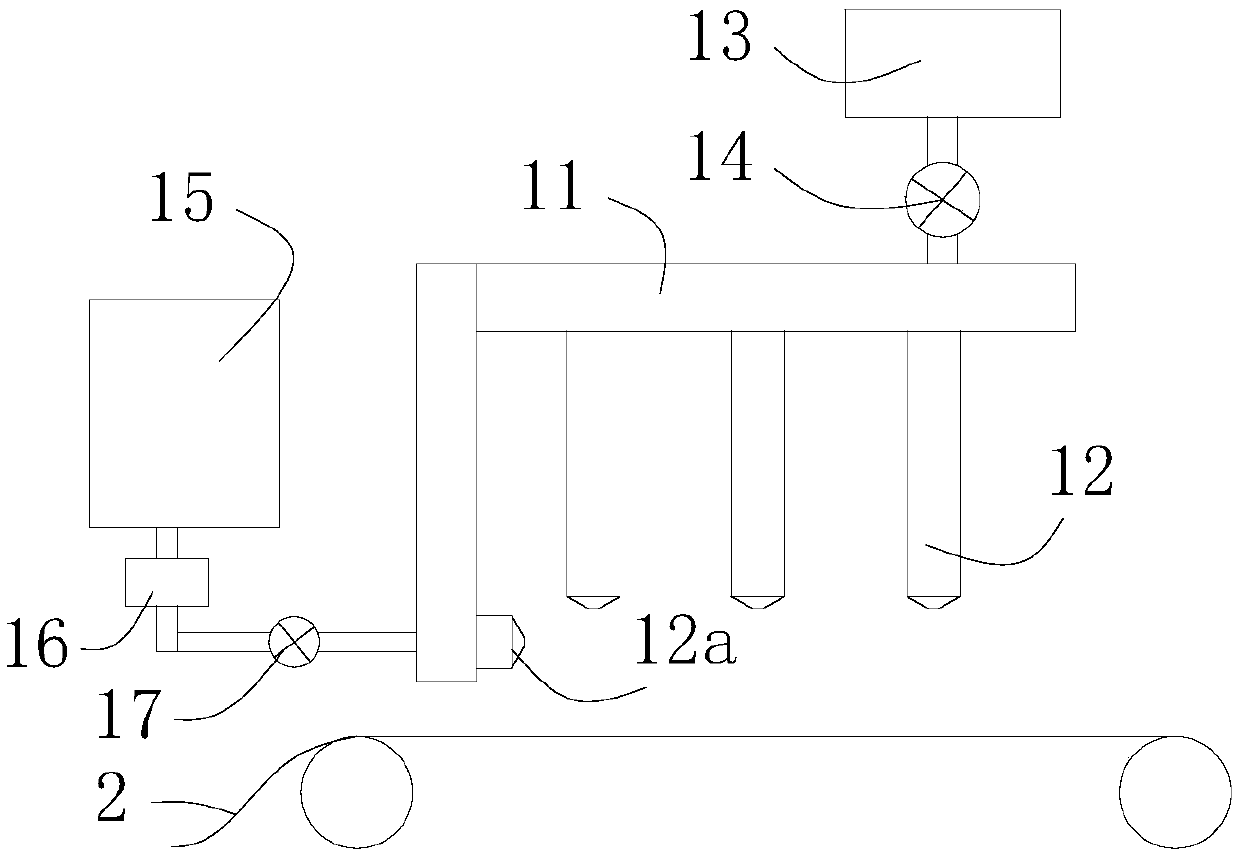

[0035] In the following, the present invention will be further described in detail in conjunction with a specific implementation method of a roll-to-roll graphene transparent conductive film continuous preparation method and accompanying drawings.

[0036] A roll-to-roll graphene transparent conductive film continuous preparation method is characterized in that it comprises the following steps carried out successively: a, to transparent film substrates (specifically PET, PEN, PMMA, PC film or PI film etc. film base material) for surface modification pretreatment, cleaning the surface and reducing surface tension, and generating polar groups on the surface; b, continuous coating of multifunctional primer on the surface of film base material to further reduce surface tension The bonding force with the graphene conductive material layer increases the number of its polar groups and adjusts the refractive index; c, coats at least one layer of graphene material layer again, and the g...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com