Control system and method for recycling of braking energy of drilling machine

A braking energy recovery and control system technology, applied in the field of oil drilling, can solve the problems of public DC bus energy fluctuations, drilling rig braking energy waste, etc., to reduce equipment depreciation and maintenance expenses, accurate monitoring and timely feedback, reduce The effect of small purchase expenditures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

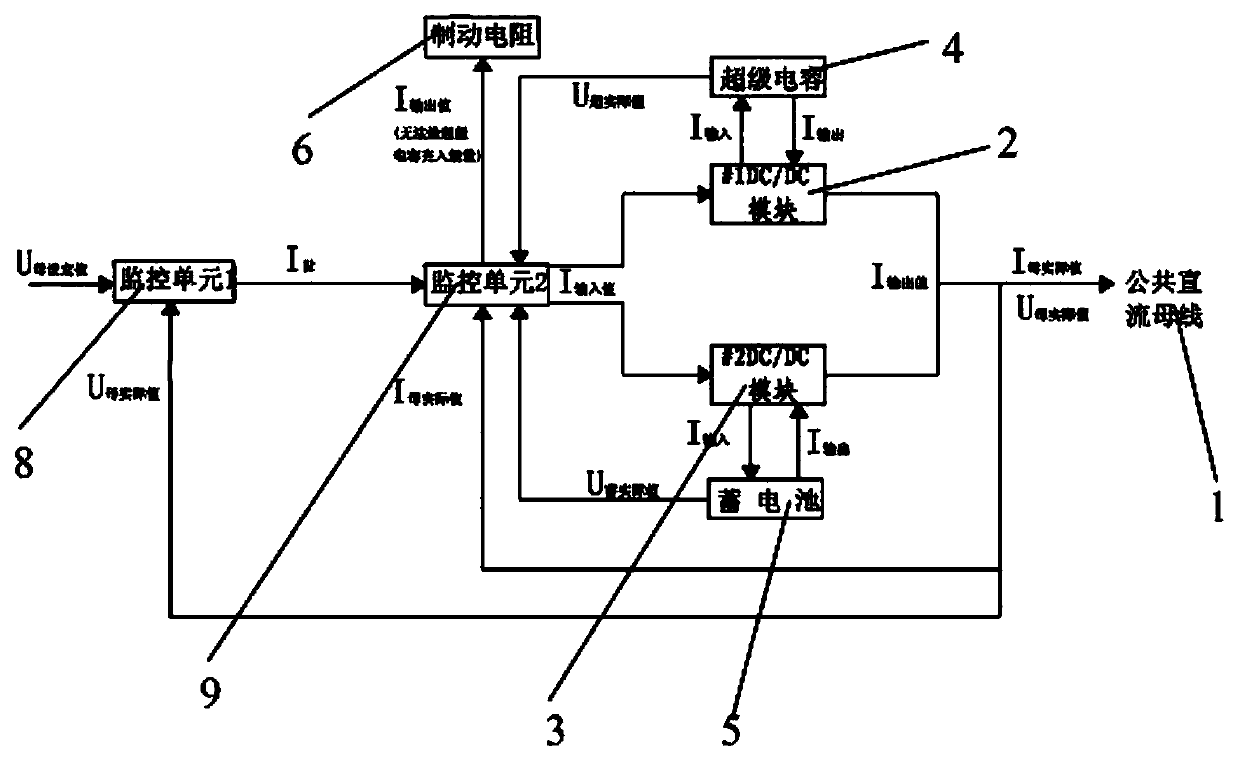

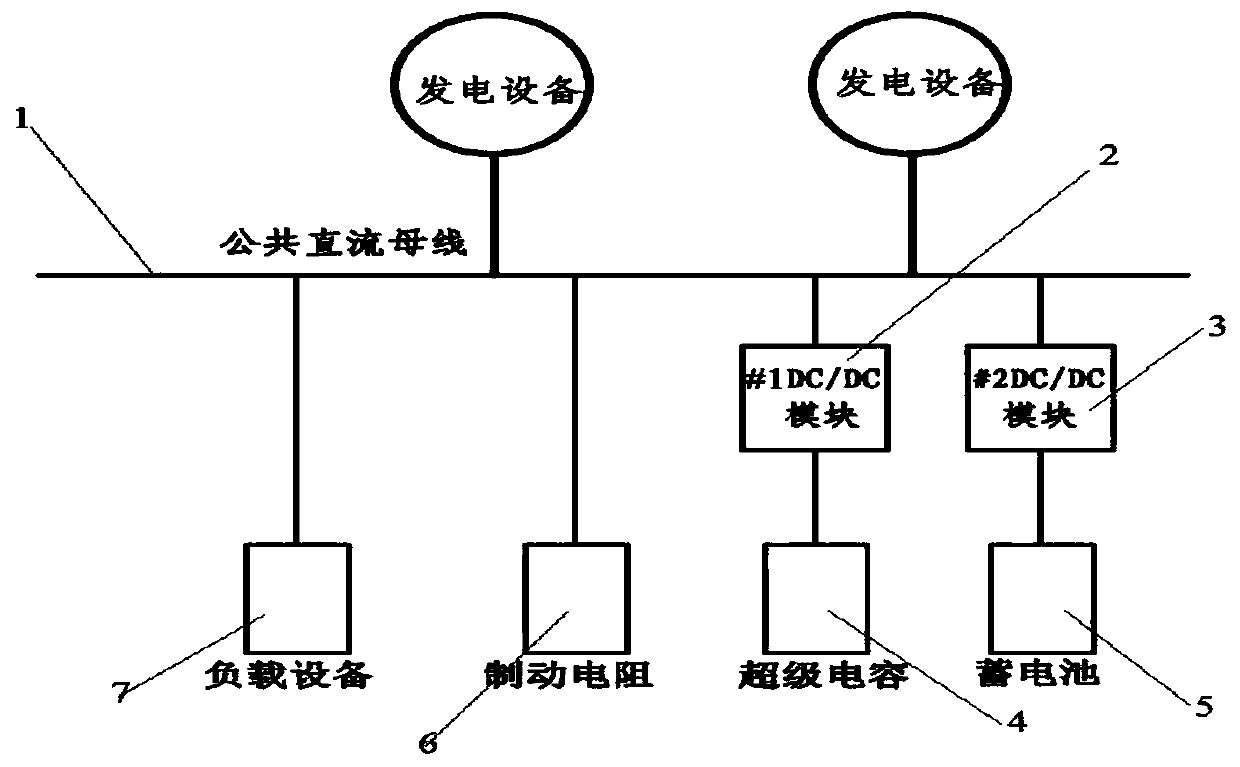

[0033]Monitoring unit a8 (FPM-7211W20131008095005) is connected to monitoring unit b9 (FPM-7211W20131008095005), monitoring unit a8 (FPM-7211W20131008095005) and monitoring unit b9 (FPM-7211W20131008095005) are connected to public DC bus monitoring 1 ( Unit b9 (FPM-7211W20131008095005) is connected to #1DC / DC module 2 (MDBF) and #2DC / DC module 3 (MDBF), and the other end of #1DC / DC module 2 (MDBF) is connected to energy storage element a4 (NBCSR09500P2R7 ), the other end of #2DC / DC module 3 (MDBF) is connected with energy storage element b5 (58500), #1DC / DC module 2 (MDBF) and #2DC / DC module 3 (MDBF) are respectively connected to the common DC bus 1 ( TMY-100x20), the monitoring unit b9 (FPM-7211W20131008095005) is also connected to the braking resistor 6 (P150).

[0034] The main components of the control system for recovery and reuse of drilling rig braking energy of the present invention are as follows:

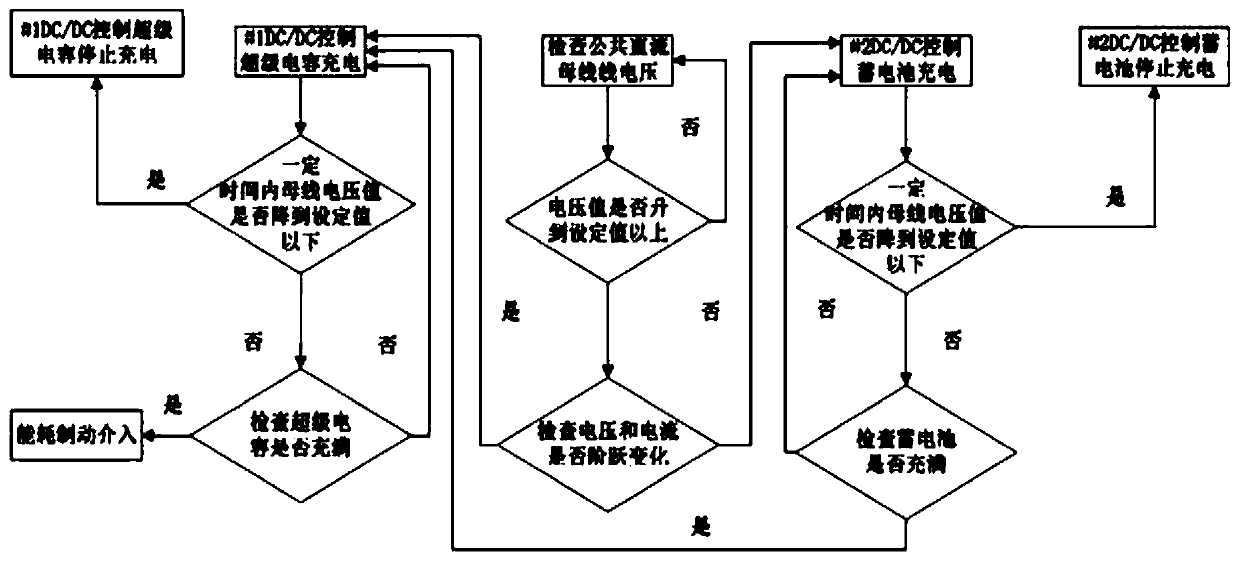

[0035] Monitoring unit b9: Control the charging and discharging proc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com