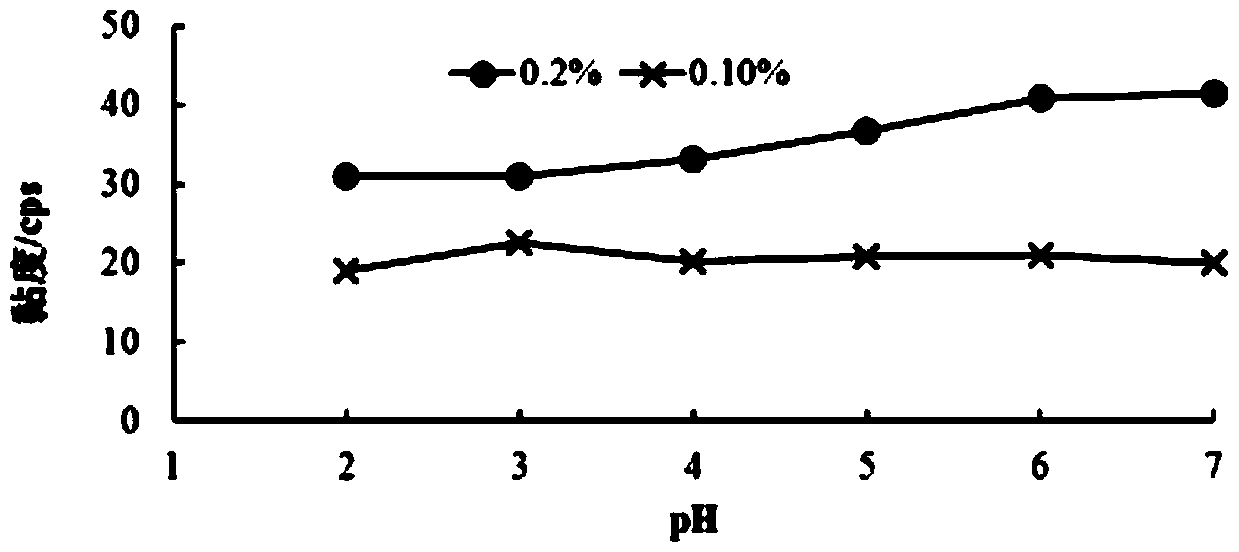

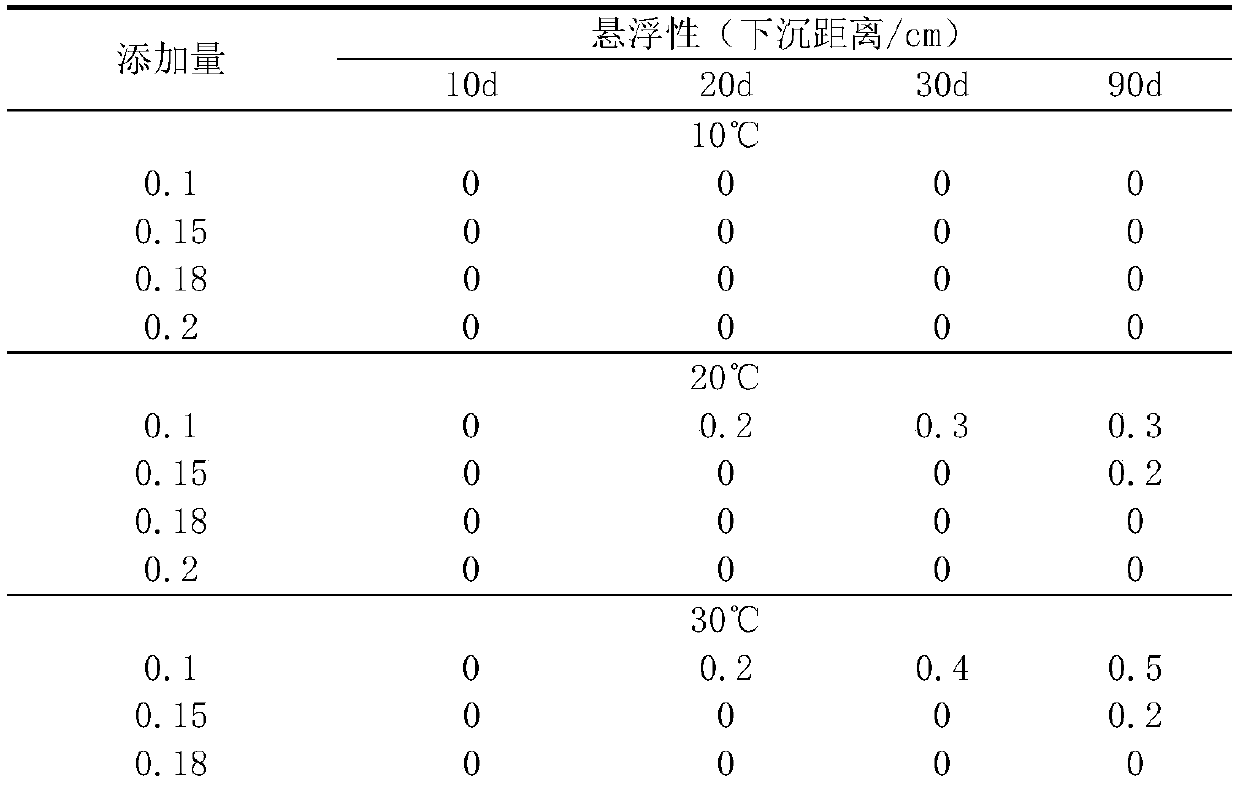

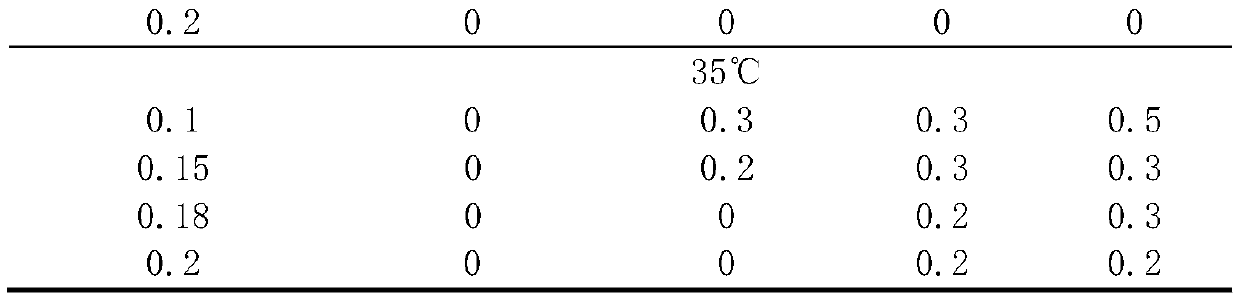

Edible agar suspending agent and preparation method thereof

A suspending agent and agar technology, which is used in food ingredients as clouding agents, food ingredients as solubility improvers, and other directions, can solve problems such as poor coexistence and narrow temperature resistance range, achieve low cost, improve sensory quality, and compatibility. good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] A preparation method for agar edible suspension, comprising the following steps:

[0037] Weigh 5kg of edible agar powder, add 100L of water, stir well and let it stand for about 30min, then heat and boil until completely dissolved; cool down the dissolved agar solution to about 80°C, add 10L of edible glycerin, and use a high-pressure homogenizer Homogenize once, the pressure of the high-pressure homogenizer is 18Mpa; stir the homogenized agar-glycerin-water mixed solution at 65-80°C for 2 hours; Machine homogenization once, the pressure of the high-pressure homogenizer is 18Mpa; then under the condition of keeping the mixed solution at 65-80°C, carry out drying and powdering with the spray drying method to obtain 5.5kg agar edible suspending agent, and the yield is 91.7%.

Embodiment 2

[0039] A preparation method for agar edible suspension, comprising the following steps:

[0040] Weigh 20kg of edible agar powder, add 1000L of water, stir well and let it stand for about 1 hour, then heat and boil until completely dissolved; cool the dissolved agar solution to about 70°C, add 50L of edible glycerin, and use a high-pressure homogenizer to Homogenize once, the pressure of the high-pressure homogenizer is 25Mpa; stir the homogenized agar-glycerin-water mixed solution at 65-80°C for 2 hours; Machine homogenization once, the pressure of the high-pressure homogenizer is 25Mpa; then under the condition of keeping the solution at 65-80° C., dry and powder with the spray drying method, 32 kg of agar edible suspending agent can be obtained, and the yield is 91.4%.

Embodiment 3

[0042] A preparation method for agar edible suspension, comprising the following steps:

[0043]Weigh 10kg of edible agar powder, add 1000L of water, stir well and let it stand for about 1 hour, then heat and boil until completely dissolved; cool the dissolved agar solution to about 80°C, add 50L of edible glycerin, and use a high-pressure homogenizer Homogenize once, and the pressure of the high-pressure homogenizer is 30Mpa; stir the homogenized agar-glycerin-water solution at 65-80°C for 2 hours; Quality once, the pressure of the high-pressure homogenizer is 30Mpa; then keep the solution under the condition of 65-80 ℃, dry and make powder with spray drying method, can obtain 19kg agar edible suspending agent, and the yield is 95.0%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com