Composite flavoring agent preparing system and method based on uniform and continuous changes of temperature

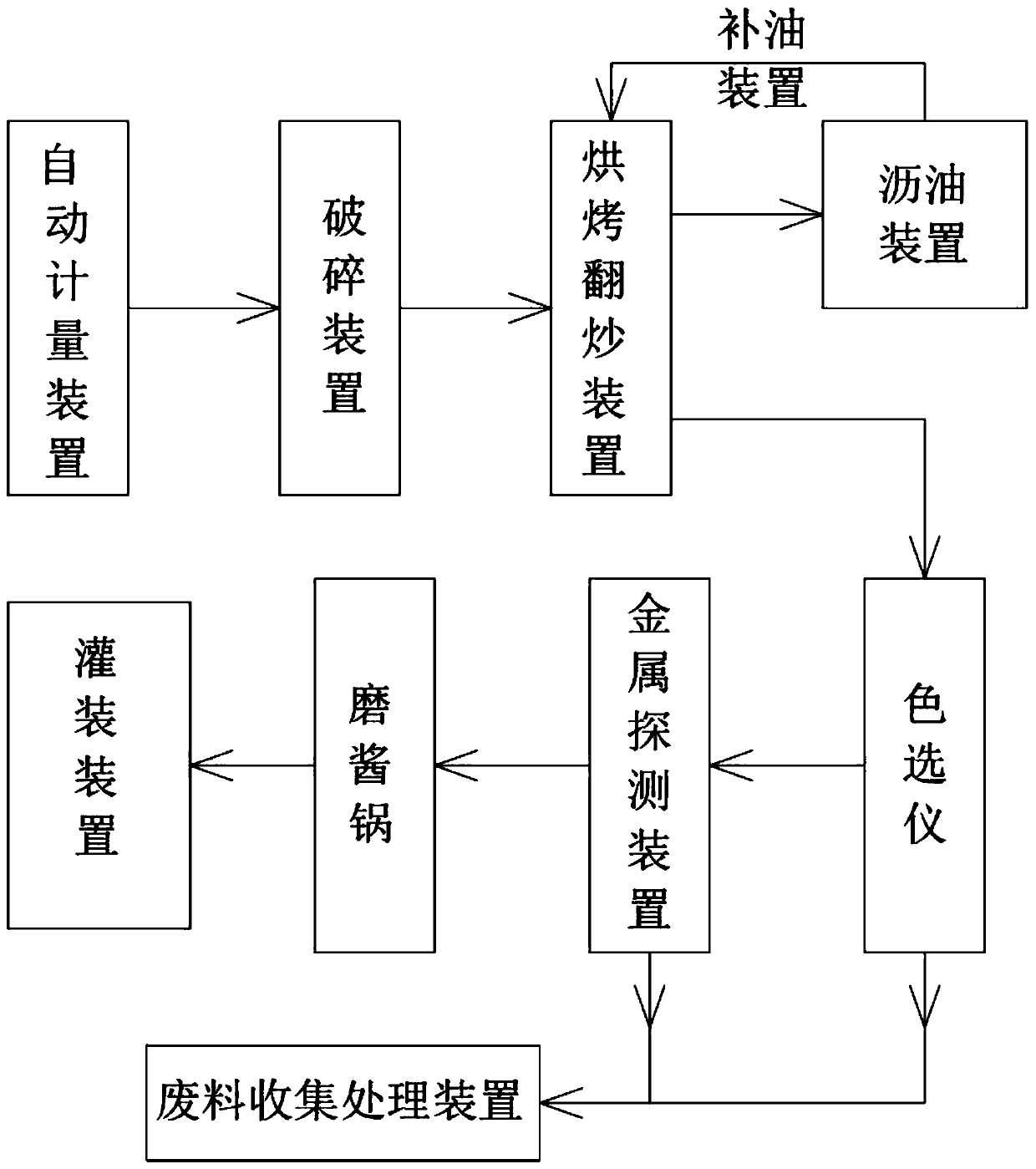

A technology for preparation system and flavoring agent, which is applied in the field of food flavoring agent processing, can solve the problems of reduced quality preservation effect, low utilization rate, and inaccurate control of heating temperature, etc., to achieve uniform heating and ripening, adding flavor and taste, Realize the effect of automatic operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] The compound flavoring agent is prepared by weight ratio from the following ingredients: stir-frying material 6, white sugar 11, salt 11, tempeh 7, soy sauce 5 and monosodium glutamate 2; wherein the stir-fry ingredients are prepared by weight ratio: peanut 7, corn 4. Rice 4, barley 2 and wheat 2; and the processing technology thereof comprises the following steps:

[0046] ① Metering, after mixing the raw materials of rice, corn, peanut, barley and wheat, they enter the automatic metering device for weighing and metering;

[0047] ②, crushing, step ① The measured raw materials are transported to the crushing device by the automatic conveyor belt for crushing, and the crushed raw materials are particles with a diameter of 4mm;

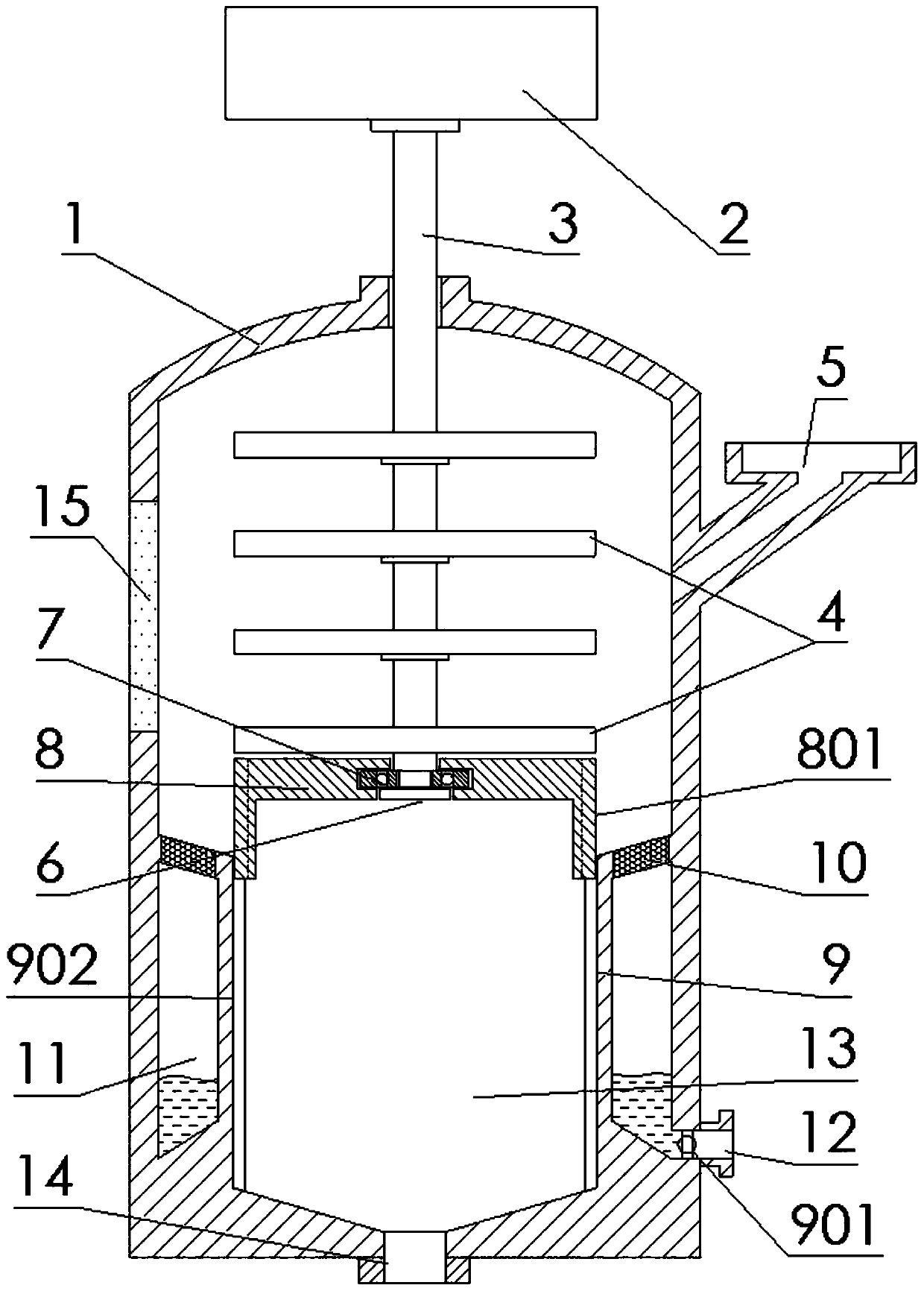

[0048] ③, roasting and stir-frying, firstly preheat the roasting and stirring device for 10 minutes; then send the crushed granular raw materials in step ② to the oven of the roasting and stirring device through the material conveying auger, In...

Embodiment 2

[0055] The compound flavoring agent is prepared by weight ratio from the following ingredients: stir-fry material 7, white sugar 12, salt 12, tempeh 8, soy sauce 6 and monosodium glutamate 3; wherein the stir-fry ingredients are prepared by weight ratio: peanut 8, corn 3~5, rice 5, barley 3 and wheat 3; and the treatment process includes the following steps:

[0056] ① Metering, after mixing the raw materials of rice, corn, peanut, barley and wheat, they enter the automatic metering device for weighing and metering;

[0057] ②, crushing, step ① The measured raw materials are transported to the crushing device by the automatic conveyor belt for crushing, and the crushed raw materials are particles with a diameter of 3mm;

[0058] ③, roasting and stir-frying, firstly preheat the roasting and stirring device for 10 minutes; then send the crushed granular raw materials in step ② to the oven of the roasting and stirring device through the material conveying auger, In the oven, the...

Embodiment 3

[0065] The compound flavoring agent is prepared by weight ratio from the following ingredients: stir-fry material 5, white sugar 10, salt 10, tempeh 6, soy sauce 4 and monosodium glutamate 1; wherein the stir-fry ingredients are prepared by weight ratio: peanut 6, corn 3. Rice 3, barley 1 and wheat 1; and the treatment process includes the following steps:

[0066] ① Metering, after mixing the raw materials of rice, corn, peanut, barley and wheat, they enter the automatic metering device for weighing and metering;

[0067] ②, crushing, step ① The measured raw materials are transported to the crushing device by the automatic conveyor belt for crushing, and the crushed raw materials are particles with a diameter of 5mm;

[0068] ③, roasting and stir-frying, firstly preheat the roasting and stirring device for 10 minutes; then send the crushed granular raw materials in step ② to the oven of the roasting and stirring device through the material conveying auger, In the oven, the f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com