Method for preparing Nd-Fe-B nanopowder through chemical method combined with pulsed magnetic field

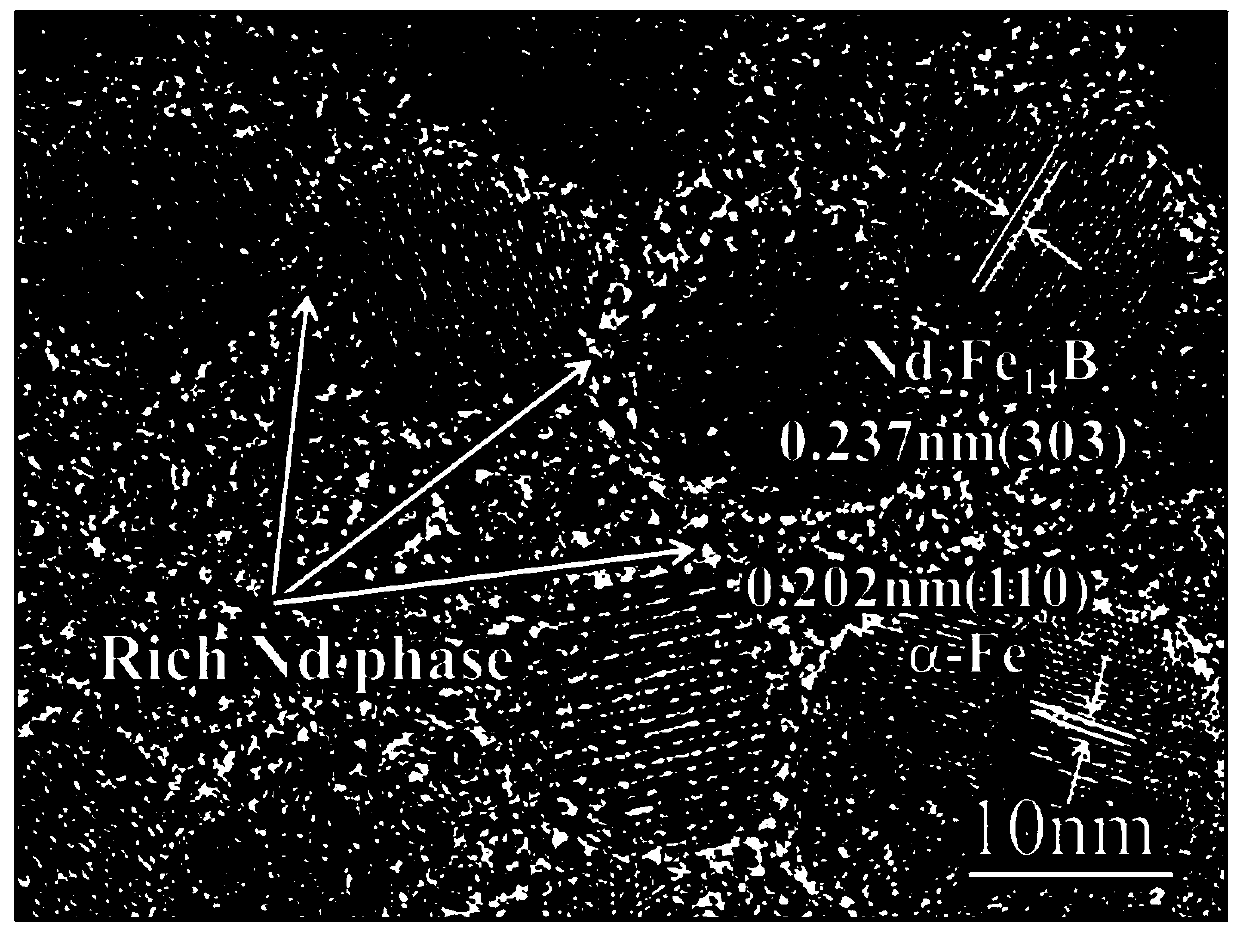

A technology of pulsed magnetic field and nano-powder, which is applied in the direction of nanotechnology, can solve the problems of poor crystallinity of crystal grains, and achieve the effects of improving the magnetic properties of particles, promoting bonding, and increasing crystallinity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

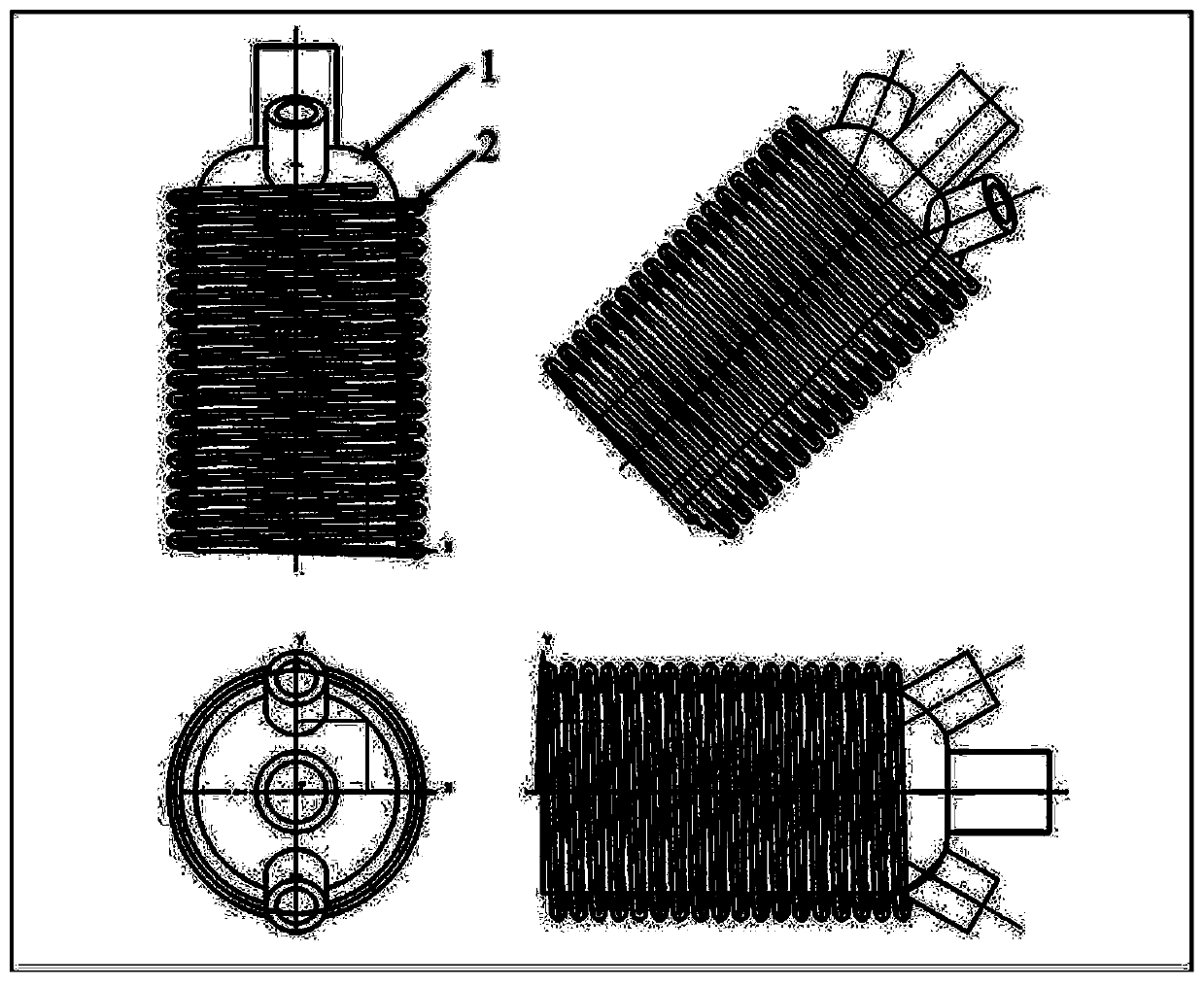

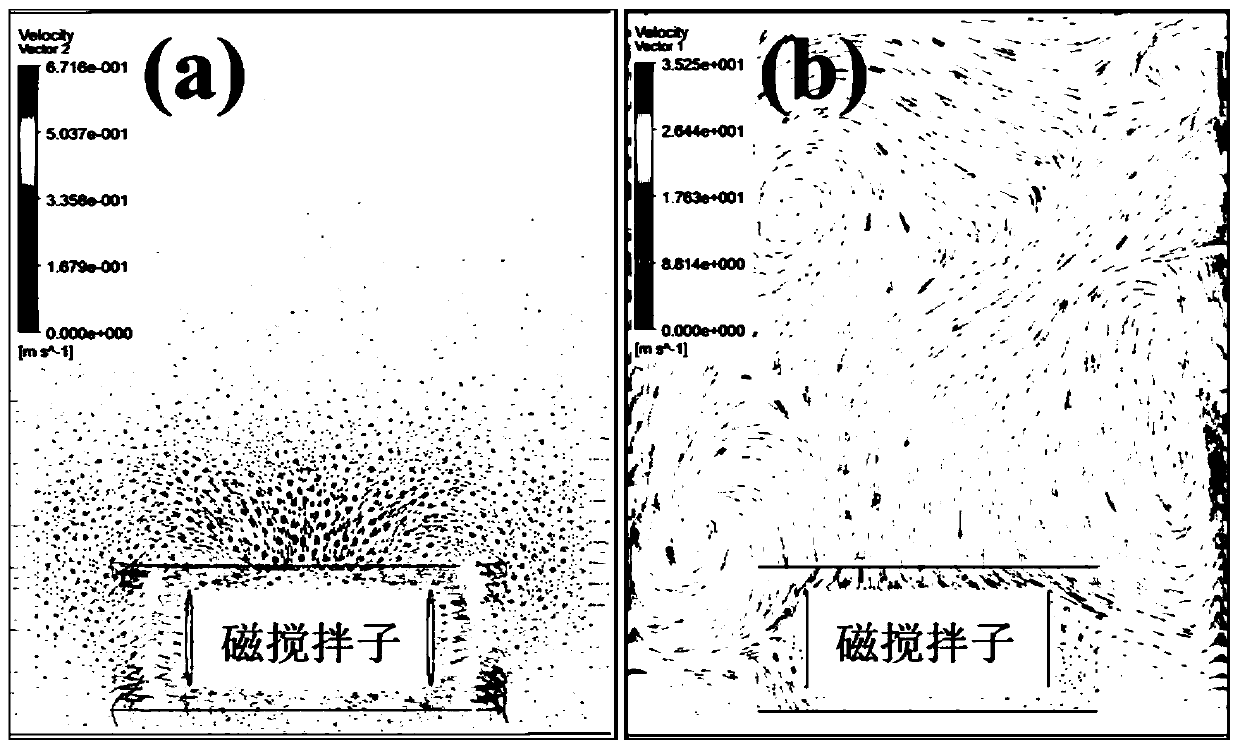

[0032] A three-necked flat-bottomed flask with a volume of 250mL was selected as the reaction device, and the induction coil was a 5mm-diameter, 10-turn helical coil. In the glove box, add 100 mL of oleylamine solution into a three-neck flat bottom flask and add 1.35 mmol Nd(acac) 3 and 7.75mmol Fe(acac) 3 , stir and dissolve at 120°C, connect the condenser, and quickly inject 1 mmol (C 2 h 5 ) 3 NBH 3 , raise the temperature to 330°C, pass a 50A current into the induction coil, control the frequency at 1Hz, keep it for 5min, and pass it in every 10min. After cooling to room temperature for 1 hour, a solution containing black particles was obtained. Then mix it with ethanol and n-hexane solution, centrifuge for 10 minutes at a centrifugal speed of 12000r / min, pour off the upper liquid, continue to add ethanol and n-hexane mixed solution, and repeat centrifugation three times to obtain black particles, which can be sealed in In the mixed solution of n-hexane and oleylamin...

Embodiment 2

[0034] A three-necked flat-bottomed flask with a volume of 250mL was selected as the reaction device, and the induction coil was a 5mm-diameter, 10-turn helical coil. In the glove box, add 100 mL of oleylamine solution into a three-neck flat bottom flask and add 1.35 mmol Nd(acac) 3 and 7.75mmol Fe(acac) 3 , stir and dissolve at 120°C, connect the condenser, and quickly inject 1mmol (C 2 h 5 ) 3 NBH 3 , raise the temperature to 330°C, pass a 100A current into the induction coil, control the frequency at 2.5Hz, keep it for 5min, and pass it in every 10min. After cooling to room temperature for 1 hour, a solution containing black particles was obtained. Then mix it with ethanol and n-hexane solution, centrifuge for 10 minutes at a centrifugal speed of 12000r / min, pour off the upper liquid, continue to add ethanol and n-hexane mixed solution, and repeat centrifugation three times to obtain black particles, which can be sealed in In the mixed solution containing n-hexane and...

Embodiment 3

[0036] A three-necked flat-bottomed flask with a volume of 250mL was selected as the reaction device, and the induction coil was a 5mm-diameter, 10-turn helical coil. In the glove box, add 100 mL of oleylamine solution into a three-neck flat bottom flask, and add 2.7 mmol Nd(acac) 3 and 15.50mmol Fe(acac) 3Stir and dissolve at 120°C, connect the condenser, and quickly inject 2mmol (C 2 h 5 ) 3 NBH 3 , raise the temperature to 330°C, pass a 150A current into the induction coil, control the frequency at 5Hz, keep it for 5min, and pass it in every 10min. After cooling to room temperature for 1 hour, a solution containing black particles was obtained. Then mix it with ethanol and n-hexane solution, centrifuge for 10 minutes at a centrifugal speed of 12000r / min, pour off the upper liquid, continue to add ethanol and n-hexane mixed solution, and repeat centrifugation three times to obtain black particles, which can be sealed in In the mixed solution containing n-hexane and ole...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com