Pneumatic and stable semiconductor wafer cutting device based on the principle of magnetic pole boosting

A cutting device and semiconductor technology, applied in the semiconductor field, can solve problems such as wash-off and wafer integrity limitation, and achieve the effect of increasing sliding property

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

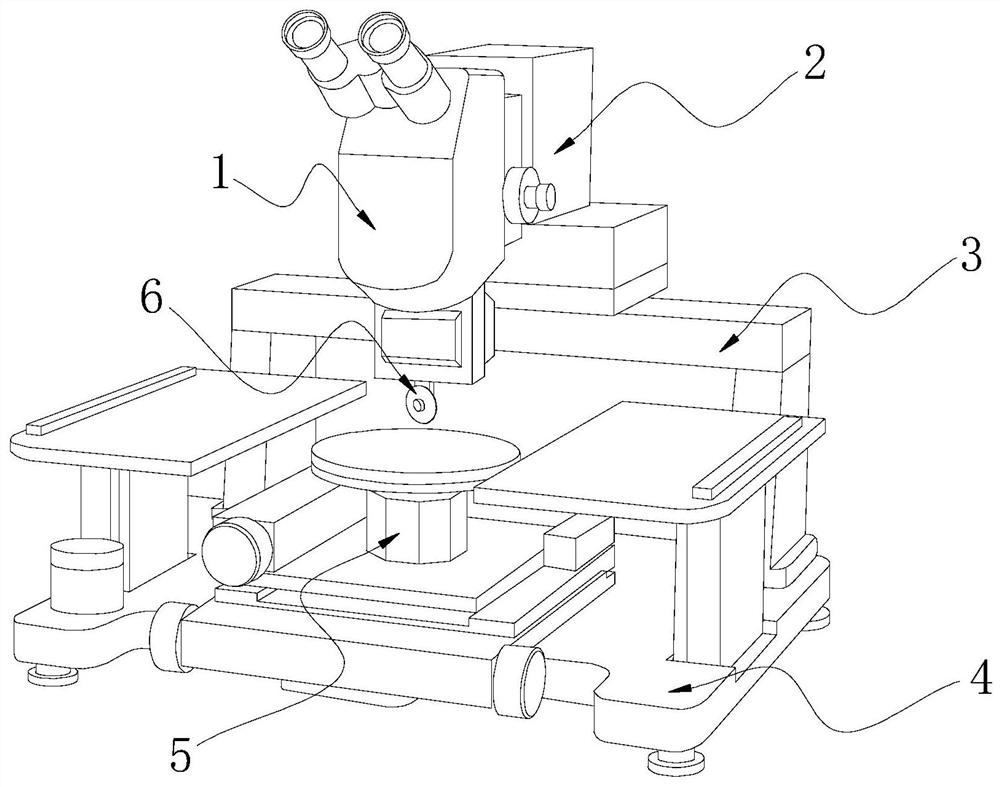

[0030] see Figure 1-Figure 7 , the present invention provides an aerodynamically stable semiconductor wafer cutting device based on the principle of magnetic pole boosting. The turntable 5 is installed on the middle part of the surface of the fixed base 4 by buckling, the top and rear end of the fixed base 4 is provided with a gantry guide frame 3, and the bottom of the mobile platform 2 is installed on the upper end of the gantry guide frame 3 by a buckling mode, and the observation The rear end of the shaft seat 1 is fitted with the front end of the mobile platform 2, and the cutter 6 is mounted on the bottom of the observation shaft seat 1 by a buckle, and the cutting work of the cutter 6 can be enlarged and observed by observing the shaft seat 1. The processing turntable 5 is used to place processed wafer plates.

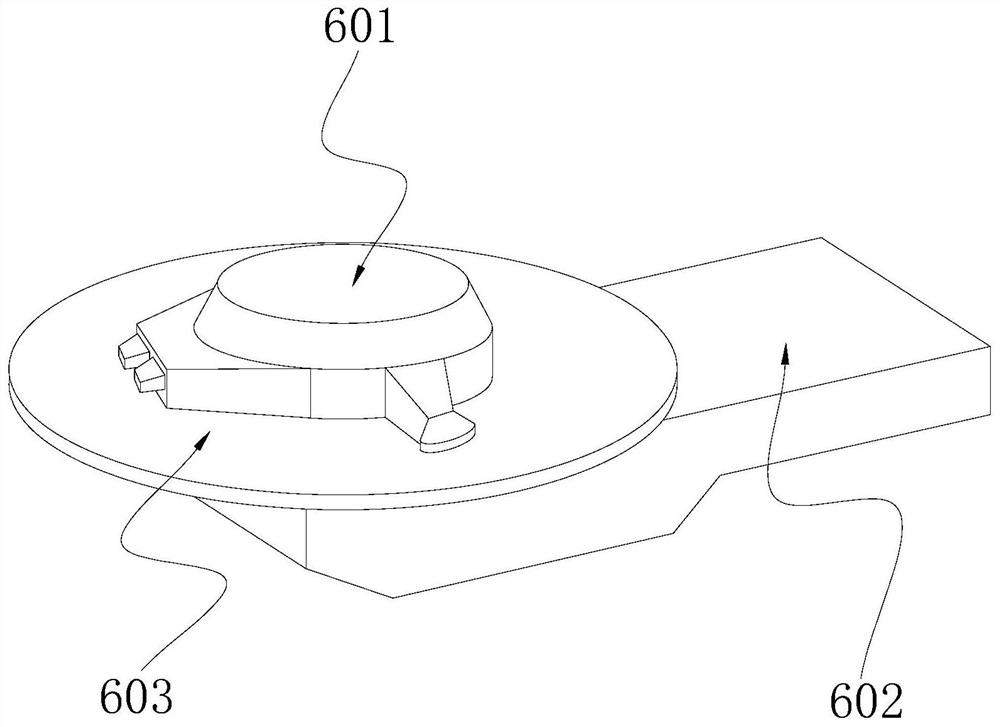

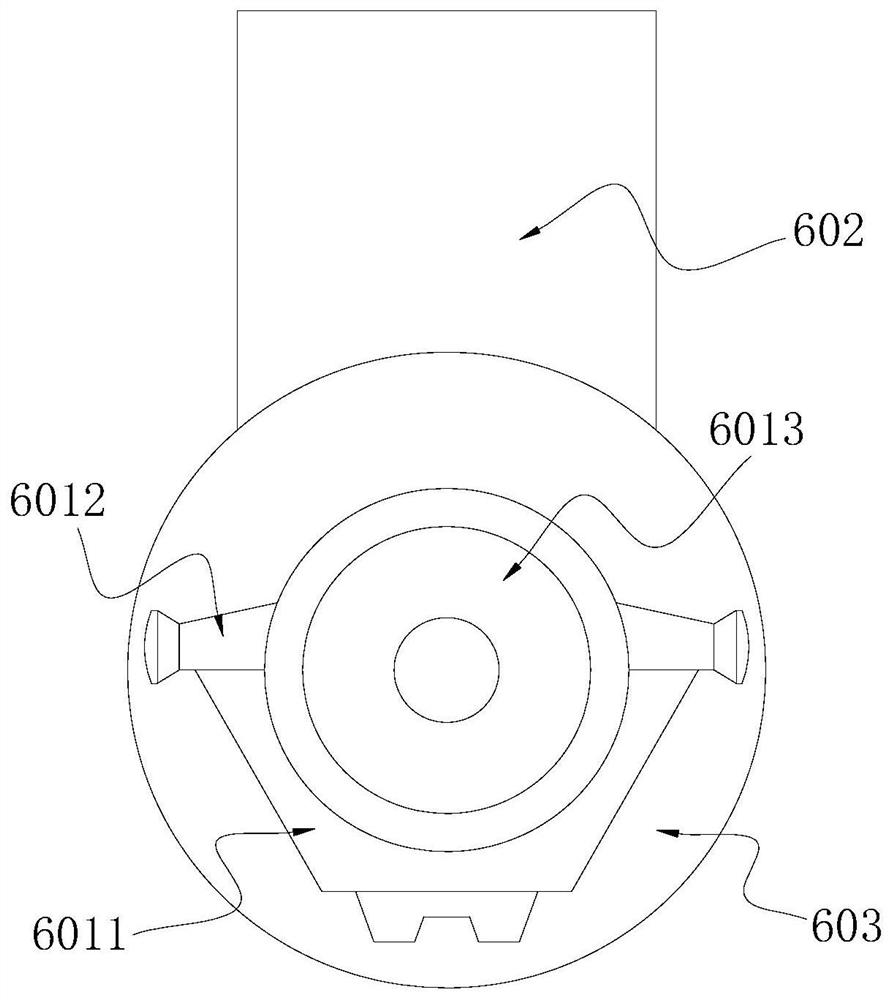

[0031] The cutter 6 includes a gravitational cooler 601, a driving arm 602, and a cutting piece 603. The front end of the driving arm 602 is provided with a c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com