Automatic cutting and packaging production system for blood glucose test strips

A technology for blood sugar test strips and production systems, applied in packaging, packaging bottles, packaging protection and other directions, can solve the problems of high labor cost and management cost, test strip failure, test strip cutting and scrapping, etc., to save labor costs and avoid product Failure, the effect of improving product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention will be further described below in conjunction with the accompanying drawings.

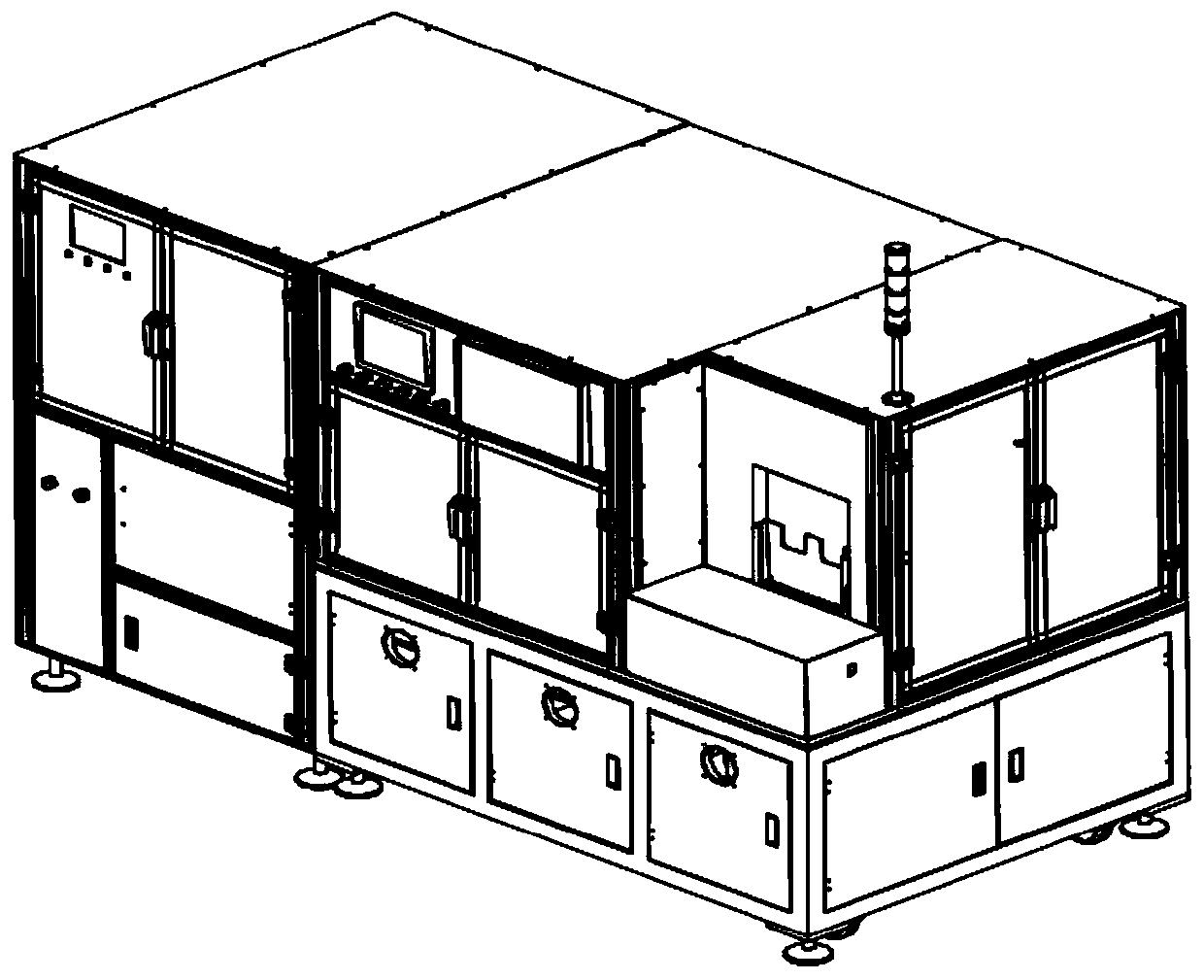

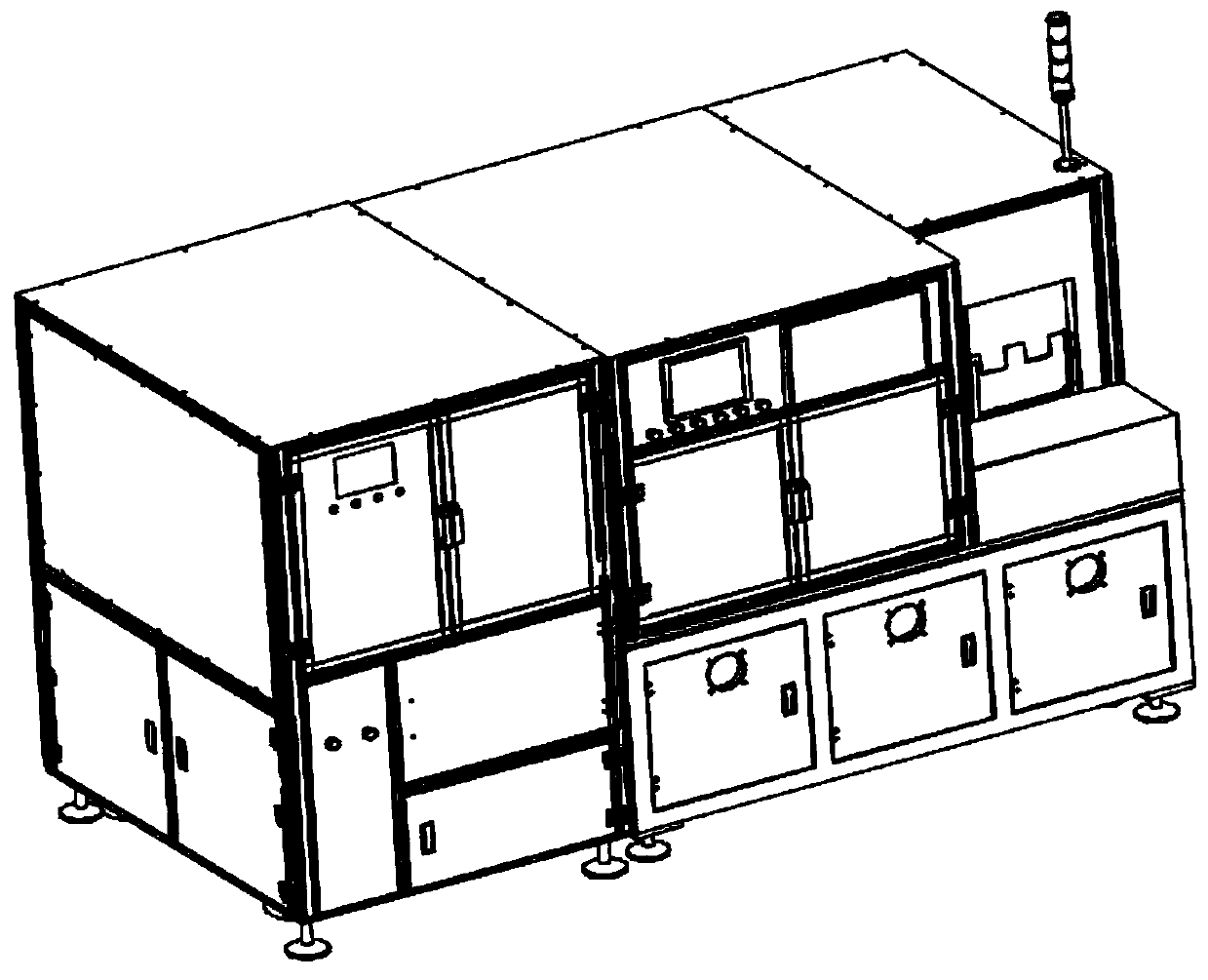

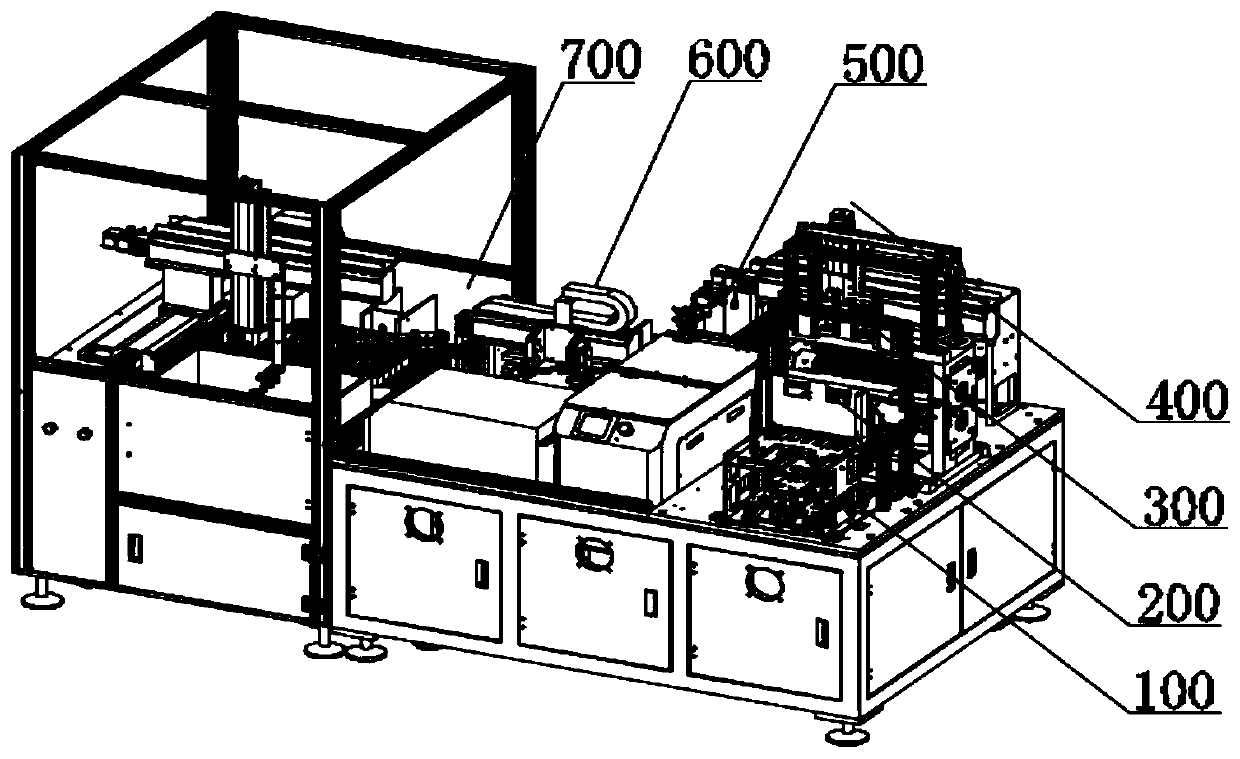

[0043] Such as Figure 2A to Figure 2B , an automatic cutting and bottling production system for blood glucose test strips, each component name is a feeding section 100, a detection section 200, a cutting section 300, a material receiving section 400, a conveying section 500, a capping section 600, and a stacking section 700;

[0044] The working principle of an automatic cutting and bottling production system for blood glucose test strips: manually or mechanically put the folded test strips neatly into the designated position of 100 in the feeding section, (50-100 pieces can be placed at a time, and the temporary storage quantity can be adjusted according to the design ), press the start key, each working section returns to the initial position, then the feeding section 100 works, the cylinder clamps the test strip and feeds it forward to the visual inspection section...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com