Controllable synthesis of zinc hydroxyfluoride nanomaterials with different morphologies and their environmental photocatalytic applications

A technology of zinc hydroxyfluoride and nanomaterials, applied in chemical instruments and methods, catalysts for physical/chemical processes, zinc halide, etc., to achieve the effects of mild reaction conditions, rich and diverse morphological features, and high yields

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] This embodiment prepares zinc hydroxyfluoride nanomaterials according to the following steps:

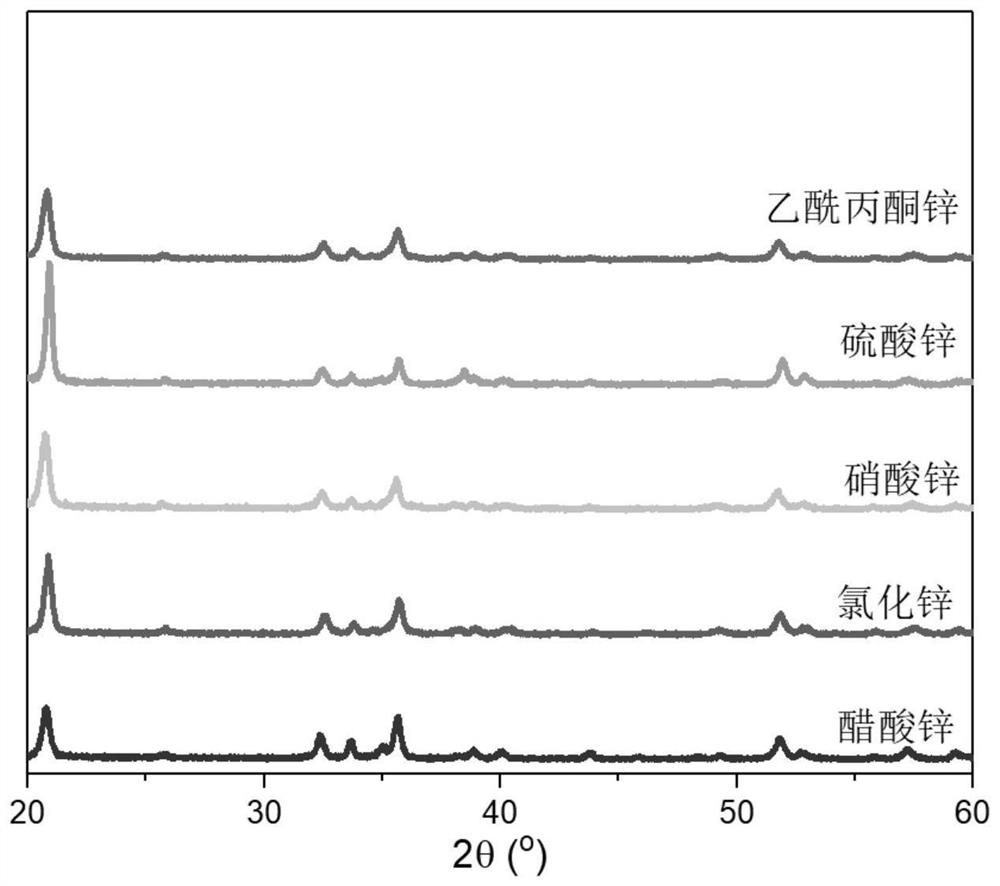

[0033] (1) Weigh 0.83g ammonium fluoride and a certain amount of zinc source (0.49g zinc acetate or 0.31g zinc chloride or 0.64g zinc sulfate heptahydrate or 0.66g zinc nitrate hexahydrate or 0.59g zinc acetylacetonate), in in a plastic beaker;

[0034] (2) Add 82 mL of solvent deionization to the beaker, and stir until the ammonium fluoride and zinc source are completely dissolved;

[0035] (3) Add 0.18 g of alkali source sodium hydroxide to the beaker, stir for 2 hours to obtain a suspension;

[0036] (4) Transfer the suspension to a 100 mL polytetrafluoroethylene liner, seal it, and conduct a hydrothermal reaction at 140° C. for 6 hours. The resulting product is washed and dried to obtain zinc hydroxyfluoride nanomaterials.

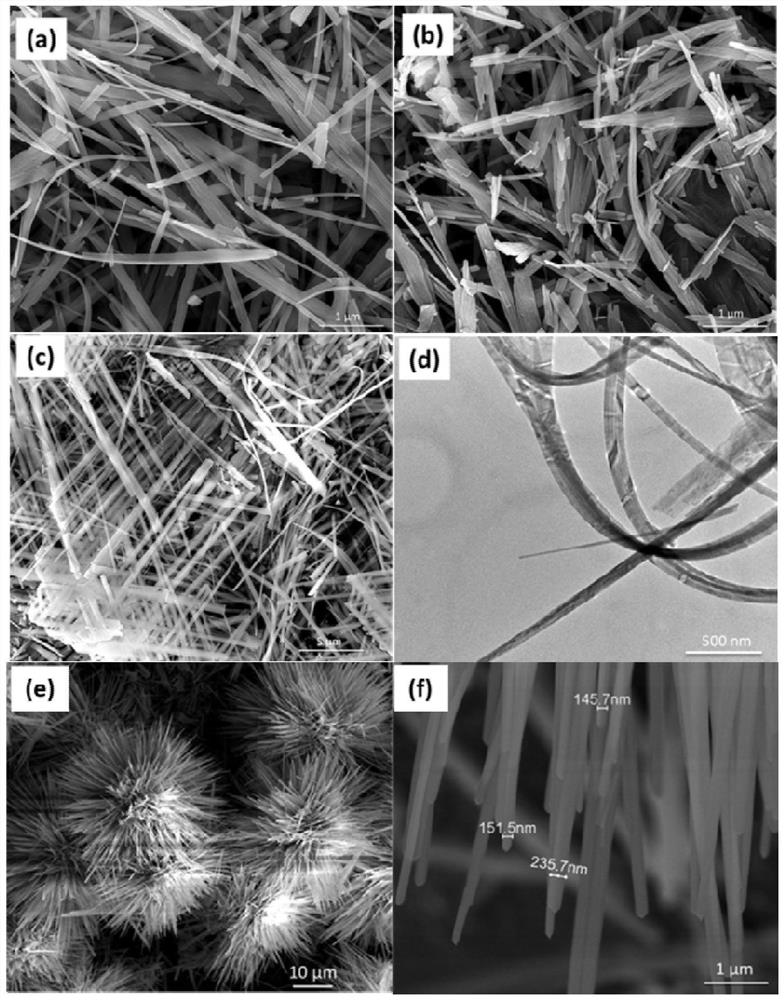

[0037] Characterize the zinc hydroxyfluoride nanomaterial prepared in this example, the results are as follows figure 1 and figure 2 shown. in,...

Embodiment 2

[0039] The method of this embodiment is the same as that of Example 1 (using zinc nitrate as the zinc source), except that the alkali source used in step (3) is tri-n-butylamine.

[0040] Such as image 3 As shown, when other conditions remain unchanged, after replacing sodium hydroxide with tri-n-butylamine, the prepared ZnF(OH) nanomaterial is a flat hat-like hierarchical structure composed of a large number of nanoribbons.

Embodiment 3

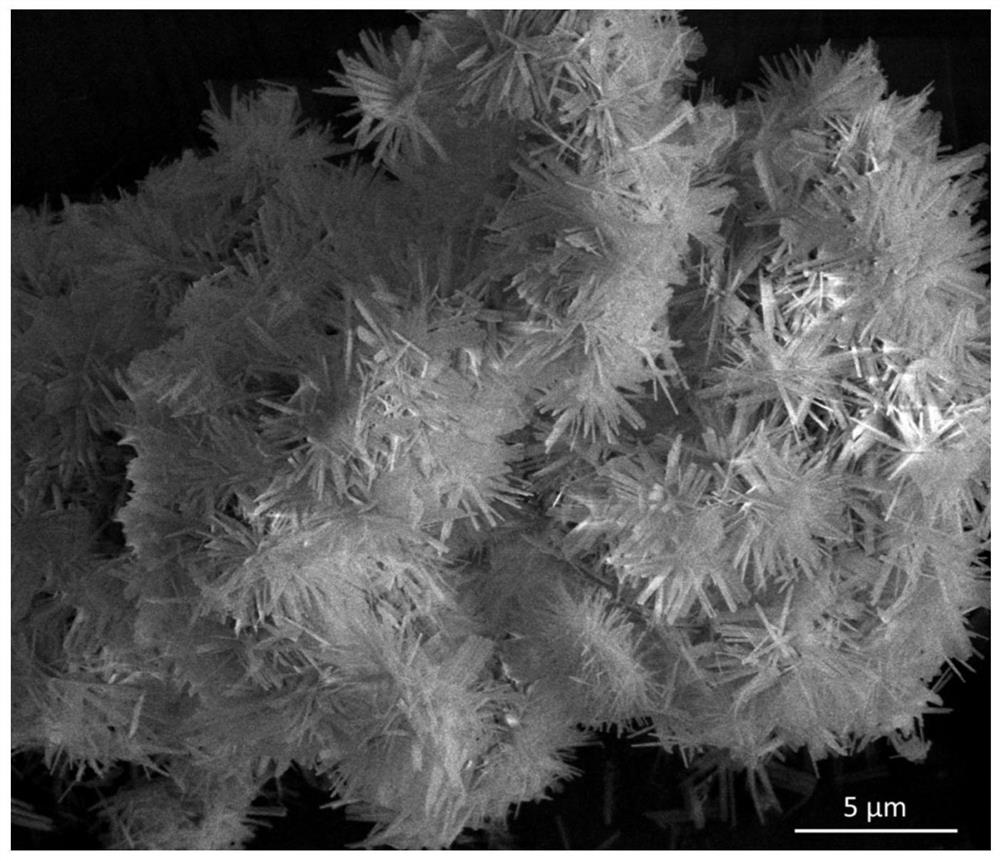

[0042] The method of this embodiment is the same as that of Example 1 (using zinc nitrate as the zinc source), except that the alkali source used in step (3) is sodium edetate.

[0043] Such as Figure 4 As shown, when other conditions remain unchanged, after replacing sodium hydroxide with sodium ethylenediamine tetraacetate, a cruciferous ZnF(OH) micro-nano graded material can be obtained.

[0044] Depend on figure 2 d. image 3 and Figure 4 It can be seen that when the alkalis added in step (3) are sodium hydroxide, tri-n-butylamine and sodium edetate, one-dimensional nanobelts, two-dimensional flat hat-like hierarchical structures and three-dimensional cross Flower-like micro-nano hierarchical structure. It can be seen that the morphology of ZnF(OH) materials can also be adjusted by controlling the type of alkali.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com