Method for preparing liquid fuel by using bio-oil

A technology for liquid fuel and bio-oil, which is used in the preparation of biological raw materials, liquid hydrocarbon mixtures, and the petroleum industry. high yield effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

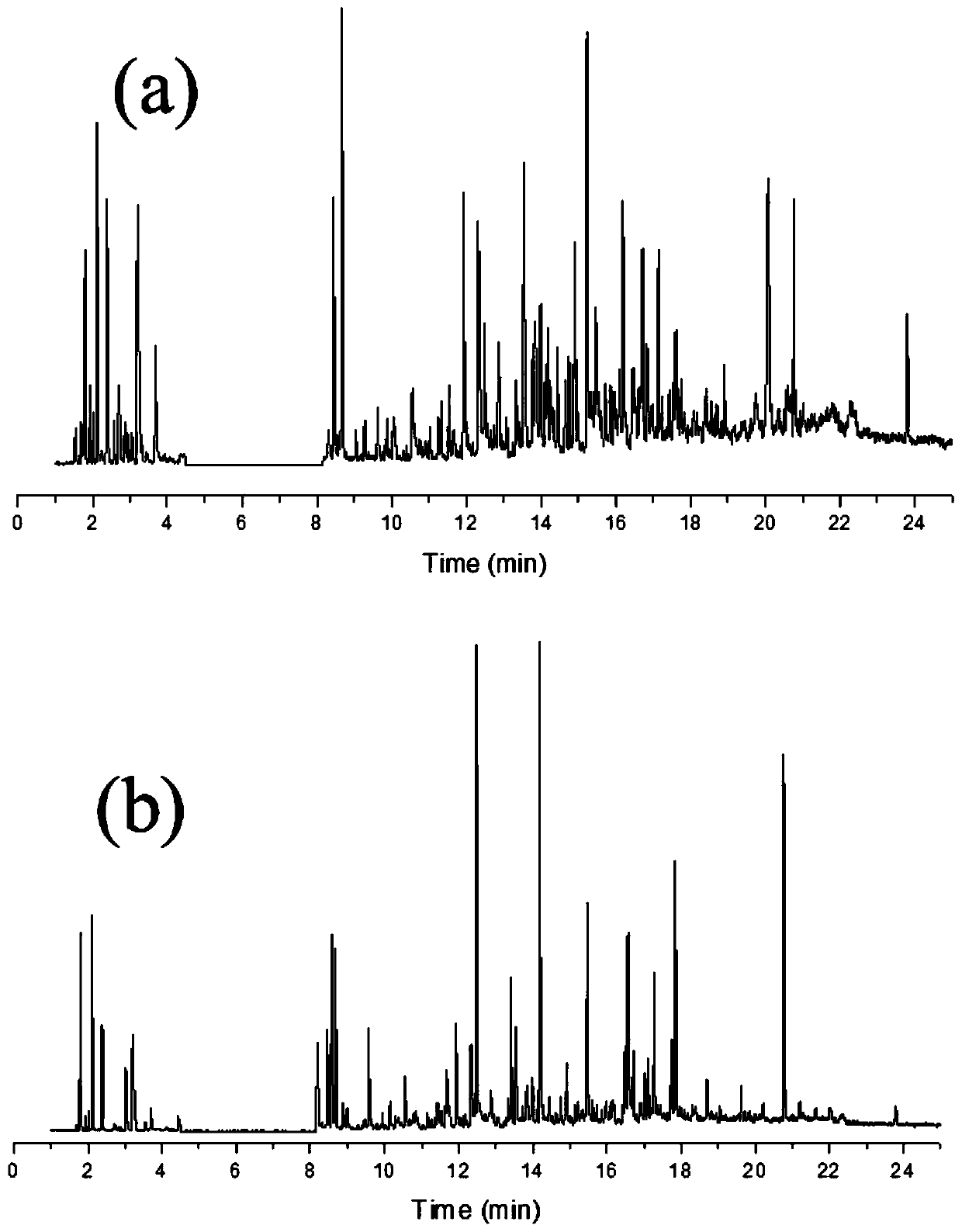

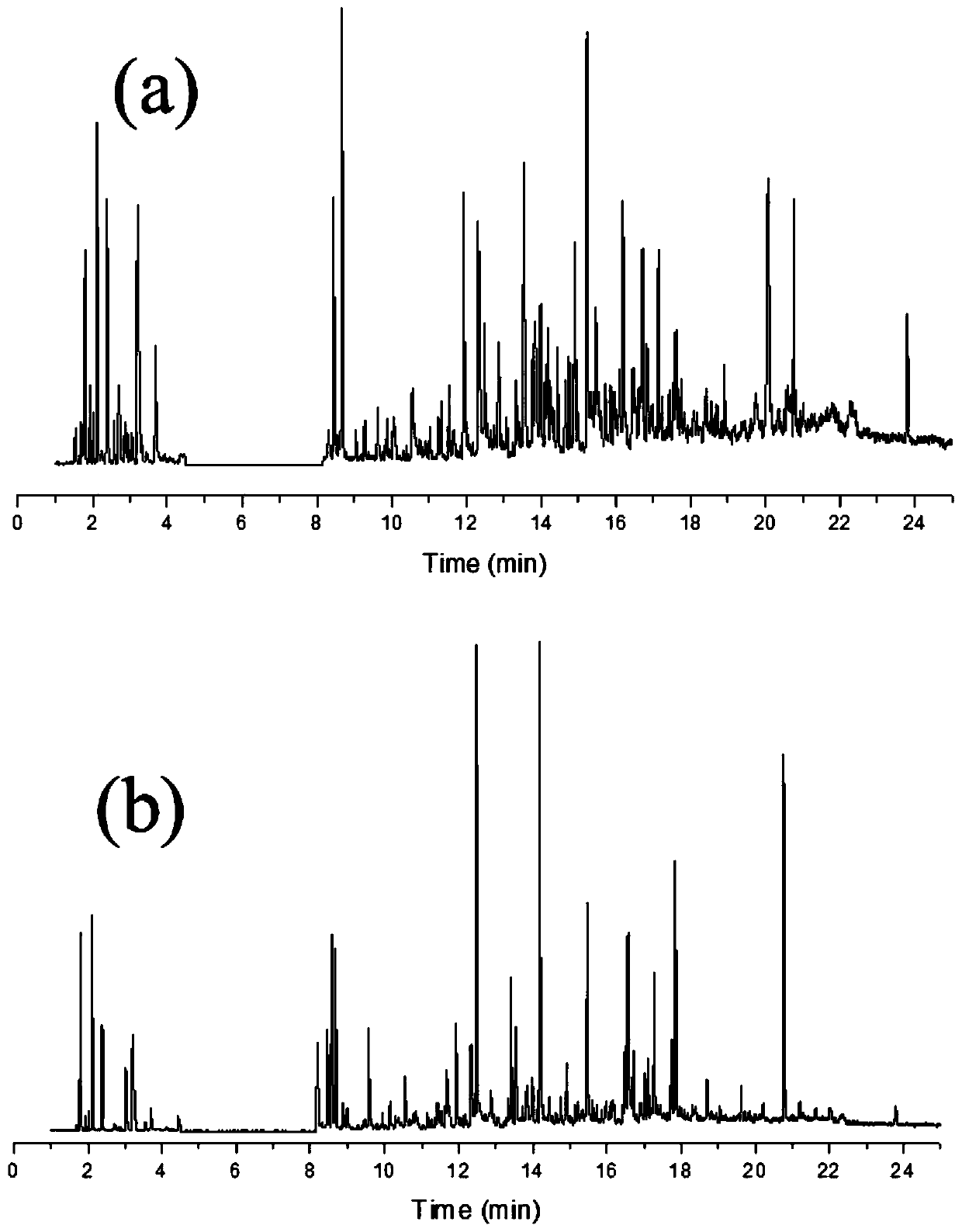

Image

Examples

Embodiment 1

[0033] (1) take bio-oil as raw material, add n-hexane solvent, the volume ratio of solvent to raw material is 10:1, fully mix and sonicate for 5 minutes, then stand for stratification to separate out the solvent phase, and obtain the extract containing the first product. n-hexane solution;

[0034] (2) get the normal hexane solution containing the first product that 20mL step (1) obtains and put into the high temperature and high pressure reactor of 50mL 316L, add the Ru / TiO of high dispersion 2 The catalyst is subjected to hydrodeoxygenation reaction, the catalyst metal loading is 2wt%, the catalyst dosage is 0.1g, the reaction temperature is 240°C, the reaction time is 4 hours, and the hydrogen pressure is 1MPa to obtain a liquid fuel.

Embodiment 2

[0036] (1) take bio-oil as raw material, add n-octane solvent, the volume ratio of solvent to raw material is 9:1, fully mix and sonicate for 8 minutes, then stand for stratification to separate the solvent phase, and obtain the first product containing the first product. n-octane solution;

[0037] (2) get the n-octane solution containing the first product that 20mL step (1) obtains and put into the high temperature and autoclave of 50mL 316L, add the Ru / TiO of high dispersion 2 The catalyst is subjected to hydrodeoxygenation reaction, the catalyst metal loading is 2wt%, the catalyst dosage is 0.2g, the reaction temperature is 300°C, the reaction time is 4 hours, and the hydrogen pressure is 1MPa to obtain a liquid fuel.

Embodiment 3

[0039](1) Take bio-oil as raw material, add n-octane solvent, the volume ratio of solvent to raw material is 5:1, fully mix and sonicate for 10 minutes, then stand for stratification to separate the solvent phase, and obtain the first product containing the first product. n-octane solution;

[0040] (2) get the n-octane solution containing the first product that 20mL step (1) obtains and put into the high temperature and autoclave of 50mL 316L, add the Ru / TiO of high dispersion 2 The catalyst is subjected to hydrodeoxygenation reaction, the catalyst metal loading is 2wt%, the catalyst dosage is 0.4g, the reaction temperature is 280°C, the reaction time is 6 hours, and the hydrogen pressure is 1MPa to obtain a liquid fuel.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com