Preparation method and preparation system of urea for vehicles

A technology for vehicle urea and preparation system, which is applied in the field of vehicle urea preparation method and preparation system, can solve the problem of not meeting the national standard requirements of diesel engine nitrogen oxide reducing agent, increasing the production cost of vehicle urea solution, and reducing the production of vehicle urea Enterprise profits and other issues, to achieve the effect of easy backwashing and maintenance, prevent nozzle clogging, and prevent catalyst deactivation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

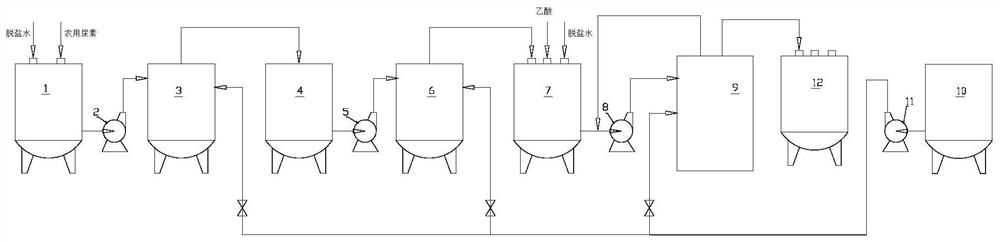

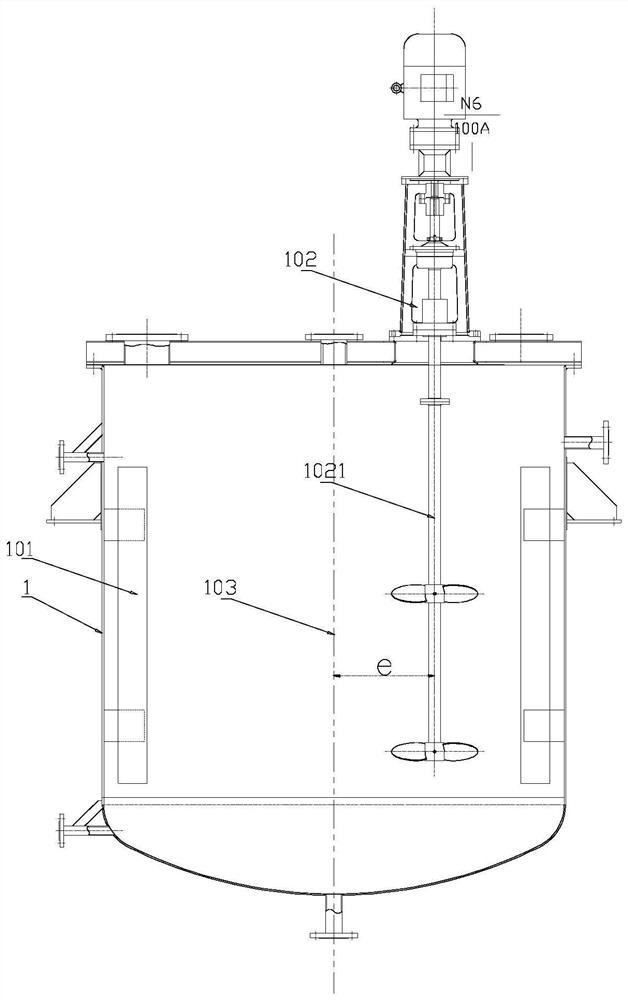

[0029] This embodiment provides a vehicle urea preparation system, including a dissolving tank 1, a first solution pump 2, a first polypropylene tow filter 3, a cooling tank 4, a second solution pump 5, and a second polypropylene tow filter 6 , reaction tank 7, the third solution pump 8, microfiltration membrane filter 9, backwash water tank 10, backwash pump 11 and finished product tank 12; There is a discharge port; the discharge port of the dissolution tank 1 is connected to the feed port of the first polypropylene tow filter 3 through the first solution pump 2, and the filtrate outlet of the first polypropylene tow filter 3 is connected to the inlet of the cooling tank 4 through a pipeline Connect, cooling tank 4 outlets are connected with the second polypropylene fiber tow filter 6 feeding ports by the second solution pump 5, the filtrate outlet of the second polypropylene fiber tow filter 6 is connected with the urea liquid inlet of reaction tank 7 tops by pipeline , the...

Embodiment 2

[0033] A preparation method of urea for vehicles, using the preparation system of embodiment 1, specifically comprises the following steps:

[0034] (1) Add 1000kg of desalted water at a temperature of 50°C in the dissolving tank 1, open the agitator, add 1500kg of agricultural urea, and stir for 0.5 to 1 hour to obtain a saturated urea solution; The urea saturated solution is pumped into the first polypropylene tow filter 3 to filter out insoluble impurities and then enters the cooling tank 4; after natural cooling in the cooling tank 4 for 0.5 to 2 hours, a cooling crystal suspension is obtained;

[0035] (2) enter retort 7 after the second solution pump 5 is pumped into the second polypropylene tow filter 6 to filter crystals by the cooling crystallization suspension in cooling tank 4, add desalted water and 100kg acetic acid in retort 7, React for 0.5 to 1 hour to obtain a urea acetate aqueous concentrate with a concentration of 30 to 35%;

[0036] (3) with the third solu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com