Microbial feed heat-insulating fermentation equipment

A technology for microbial feed and thermal insulation fermentation, which is applied in biochemical equipment and methods, bioreactor/fermenter combinations, bioreactors/fermenters for specific purposes, etc., can solve problems such as uneven fermentation, and improve fermentation quality. , strong practicability, novel design effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

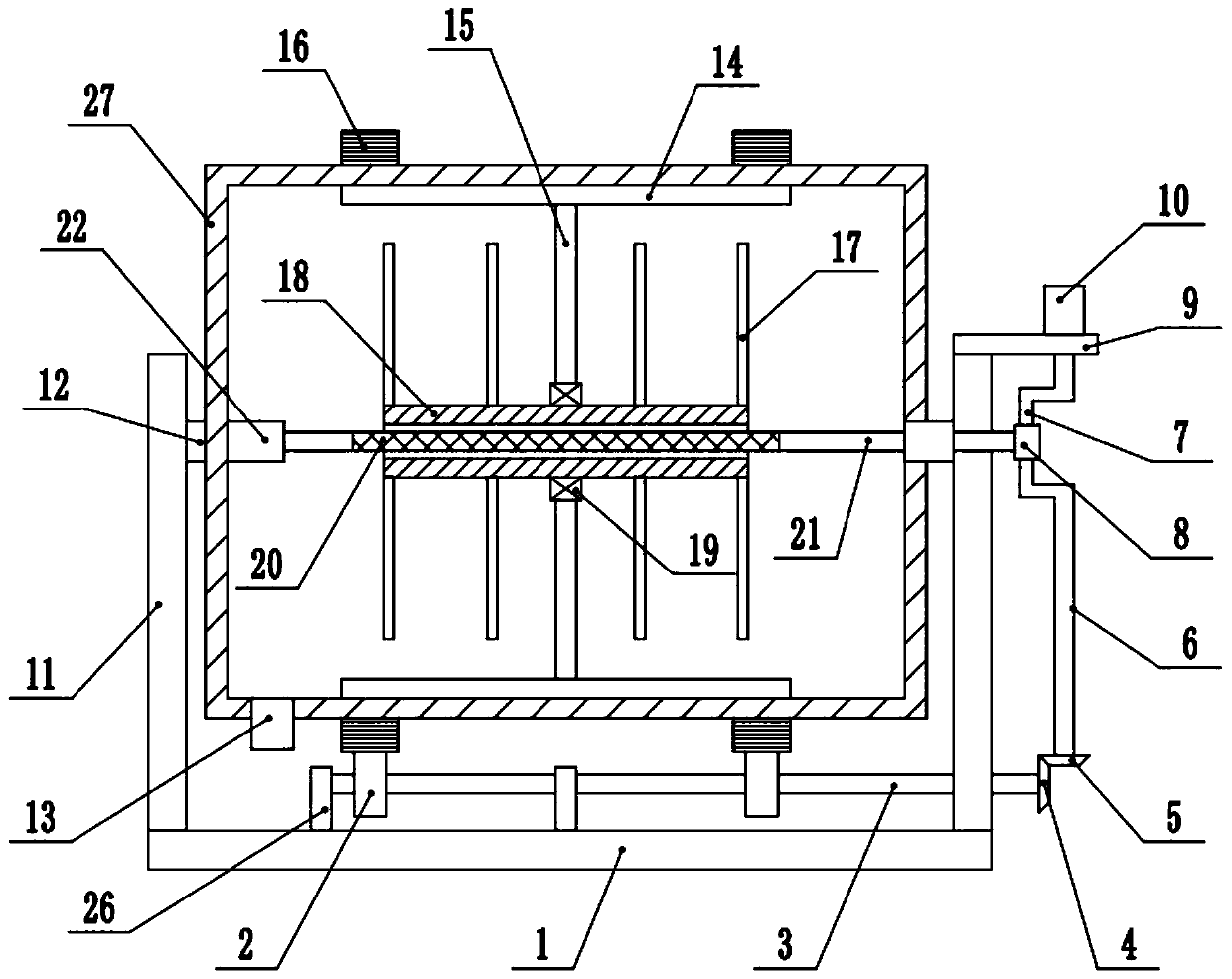

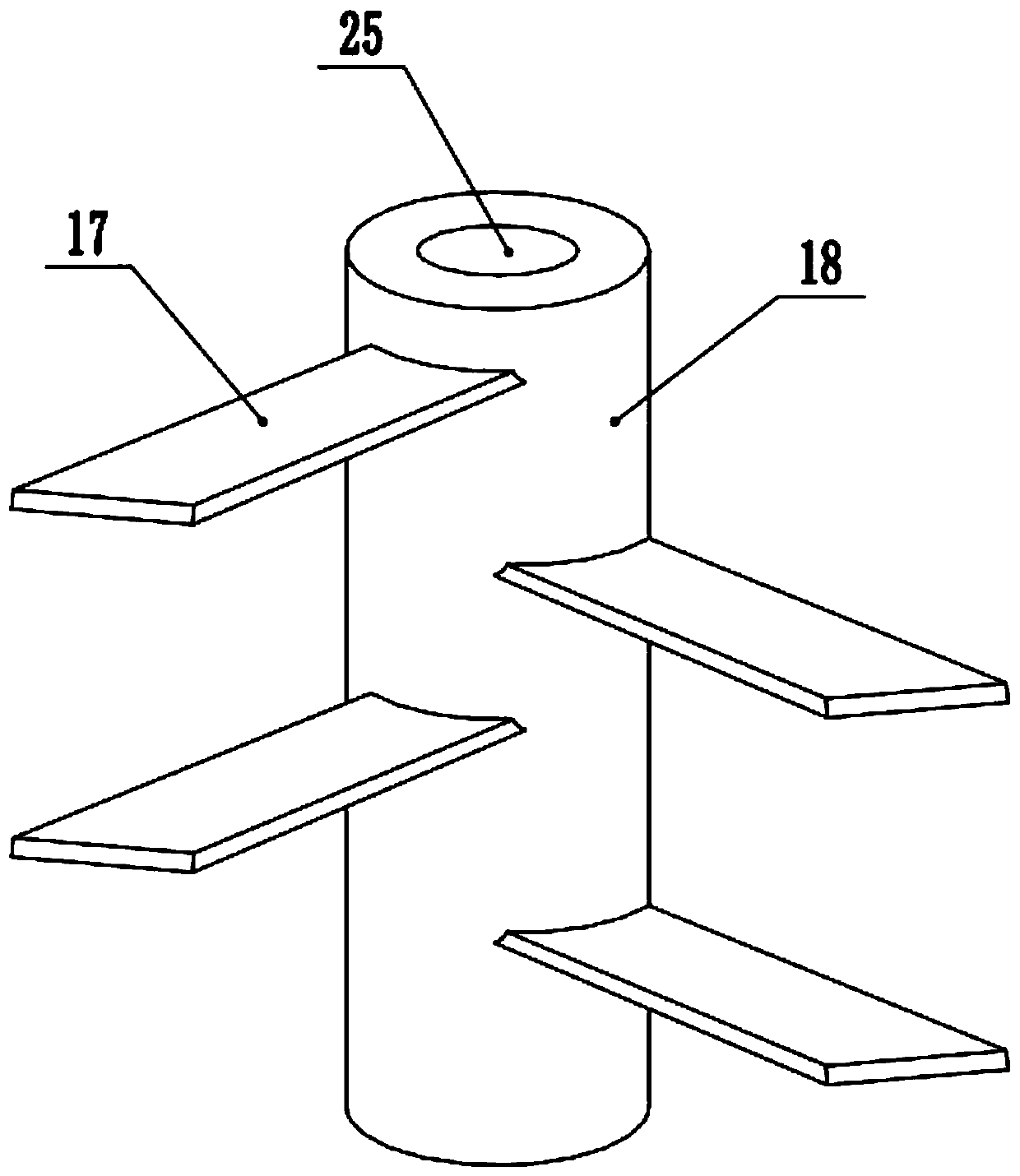

[0026] refer to Figure 1~3 , in an embodiment of the present invention, a microbial feed heat preservation and fermentation equipment includes a fixed bottom plate 1, a support frame 11 is installed on both sides of the upper end of the fixed bottom plate 1, and a rotating cylinder 12 is installed in the middle of the inner side of the support frame 11. Between the rotating cylinders 12 Fermentation tank 27 is installed, so that fermentation tank 27 can rotate along the upper end of support frame 11 through the effect of rotating cylinder 12, and described fermentation tank 27 is made of heat-insulating material, has further ensured the insulation effect of fermentation tank 27 inside, so The middle part of the upper end of the fixed bottom plate 1 is connected with the rotating shaft 3 through the fixed bracket 26, the rotating gear 2 is installed in the middle part of both ends of the rotating shaft 3, and the upper end of the rotating gear 2 is meshed with the ring teeth 16...

Embodiment 2

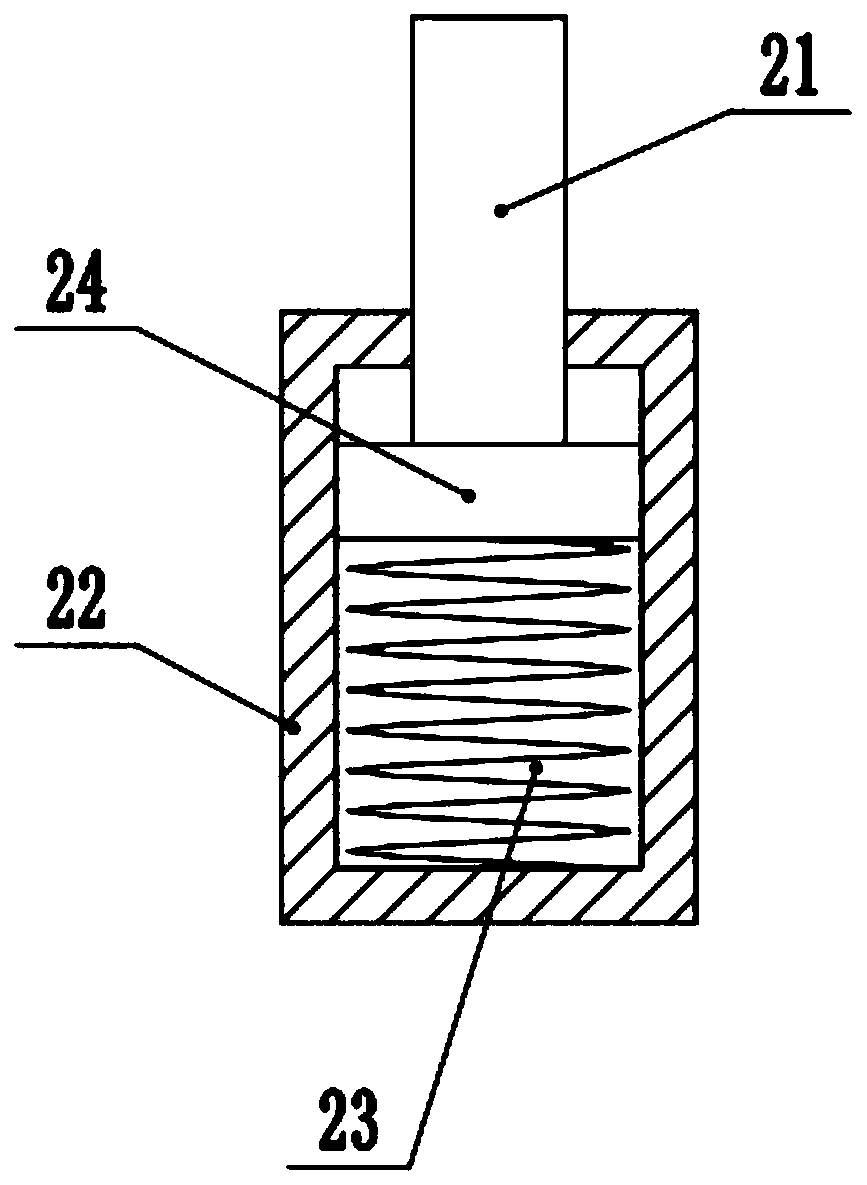

[0028] In another embodiment of the present invention, the difference between this embodiment and the above-mentioned embodiment is that a limiting cylinder 22 is installed in the middle of the inner left end of the fermenter 27, and a limiting block 24 is arranged inside the limiting cylinder 22. The right end of block 24 is fixedly connected with telescopic rod 21, and the limit spring 23 is installed in contact with the limit block 24 inside the limit tube 22, by setting the limit tube 22, the limit block 24 and the limit spring 23. The left and right movement of the telescopic rod 21 inside the fermenter 27 is limited and guided to avoid deviation during its movement, which further increases the reliability of the entire device.

[0029] In the present invention, when in use, the microbial inoculant is first added to the fermenter 27 through the inlet and outlet pipe 13, and the biological feed is put into it at the same time, then the sealing cover is closed, the drive mot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com