Ide rice warp clamping dyeing method

A dyeing method and acid dyeing technology, which is applied in the field of textile printing and dyeing, can solve the problems of reducing pollution discharge, thread adhesion, hard hand feeling, etc., and achieve the effects of preventing blooming, saving production costs, and ensuring cleaning quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

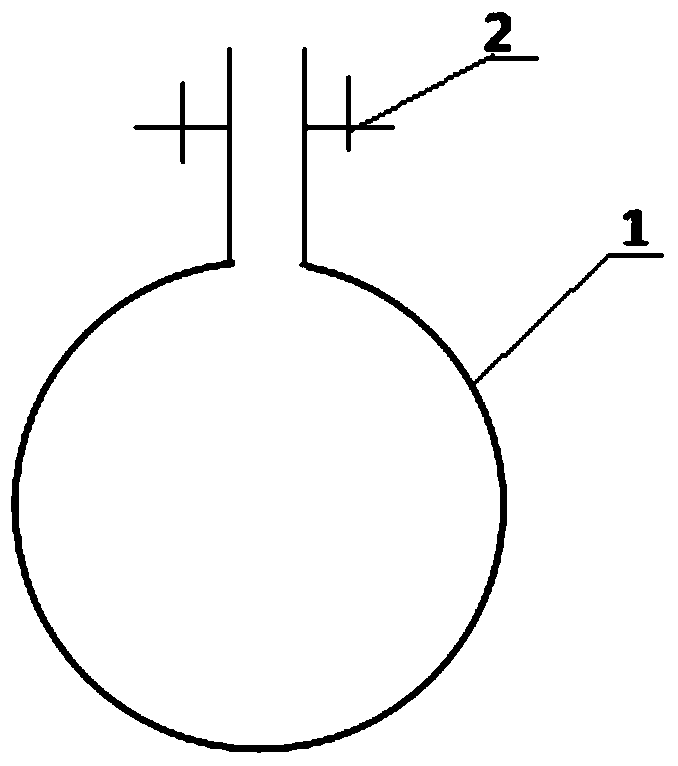

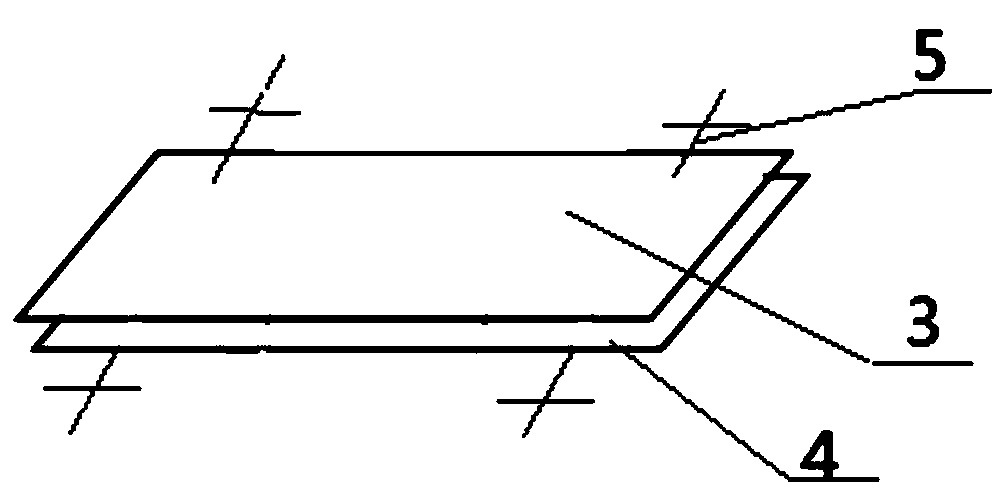

Image

Examples

Embodiment 1-12

[0057] Preparation of dyeing solution, pattern design, warp the silk thread in bundles, hang the warp-tying frame, leave a blank for the warp-tying, use the warp clamp to clamp the silk thread to be dyed in the first color, soak the color at room temperature, put the warp-tying frame Relax, immerse the silk thread to be dyed directly in the dyeing solution and then take it out, or brush the dyeing solution on the part of the thread to be dyed with a row brush, or use a small watering can to pour the dyeing solution on the part of the thread to be dyed, every dyed color The amount of dyeing solution accounts for 0.6-1.0% of the weight of the silk thread to be dyed, the dyeing temperature is 15-35°C, dry in the shade, remove the warp clamp that has soaked the silk thread of the first color, and use Soak in the dye solution, dry in the shade, remove the warp gripper that has dyed the second color silk thread, and use the dye solution to dip the warp of the silk thread to be dyed i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com