Magnetic control graphene field effect transistor sensor, and manufacturing, measuring and detecting method thereof

A technology of field effect tube and manufacturing method, which is applied in the field of analytical chemistry, can solve problems such as damage to biological samples, and achieve good and high sensitivity effects

Active Publication Date: 2019-07-05

SHANDONG NORMAL UNIV

View PDF7 Cites 1 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, when the electric field is enhanced, it may damage biological samples, and the sensitivity of biomolecular detection needs to be further improved

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

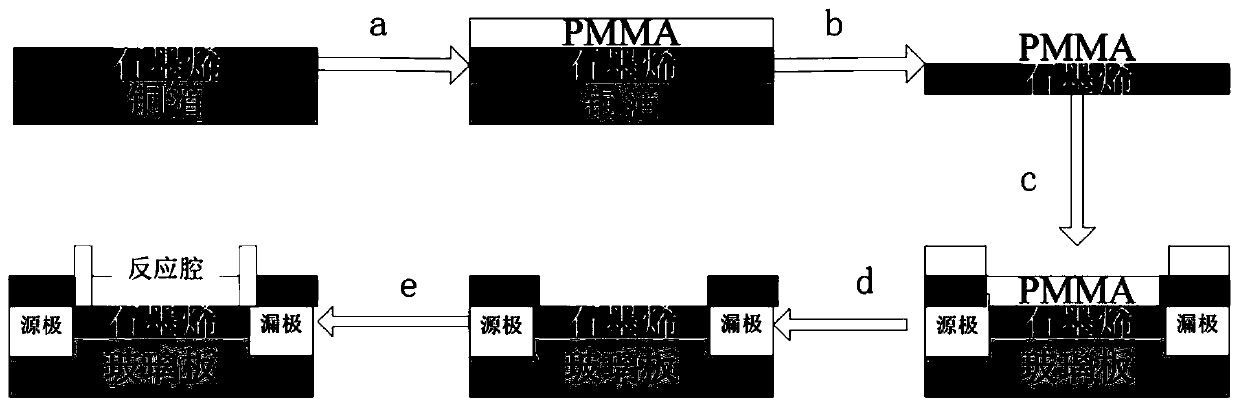

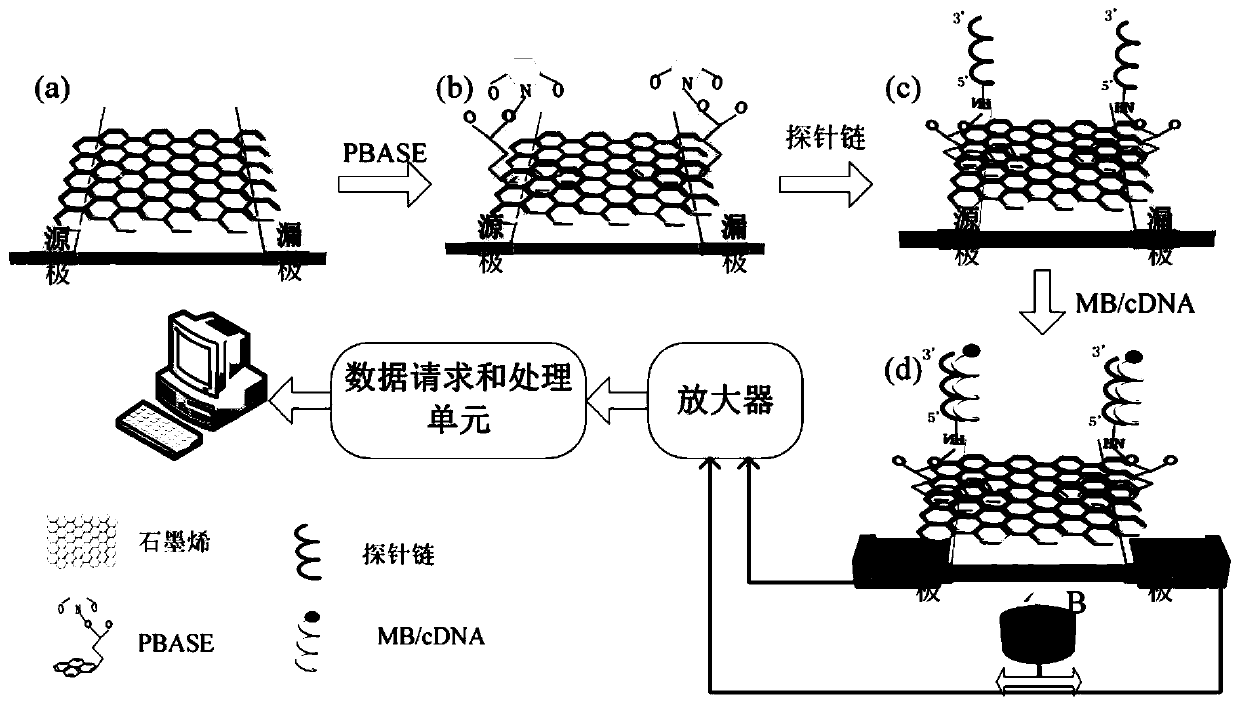

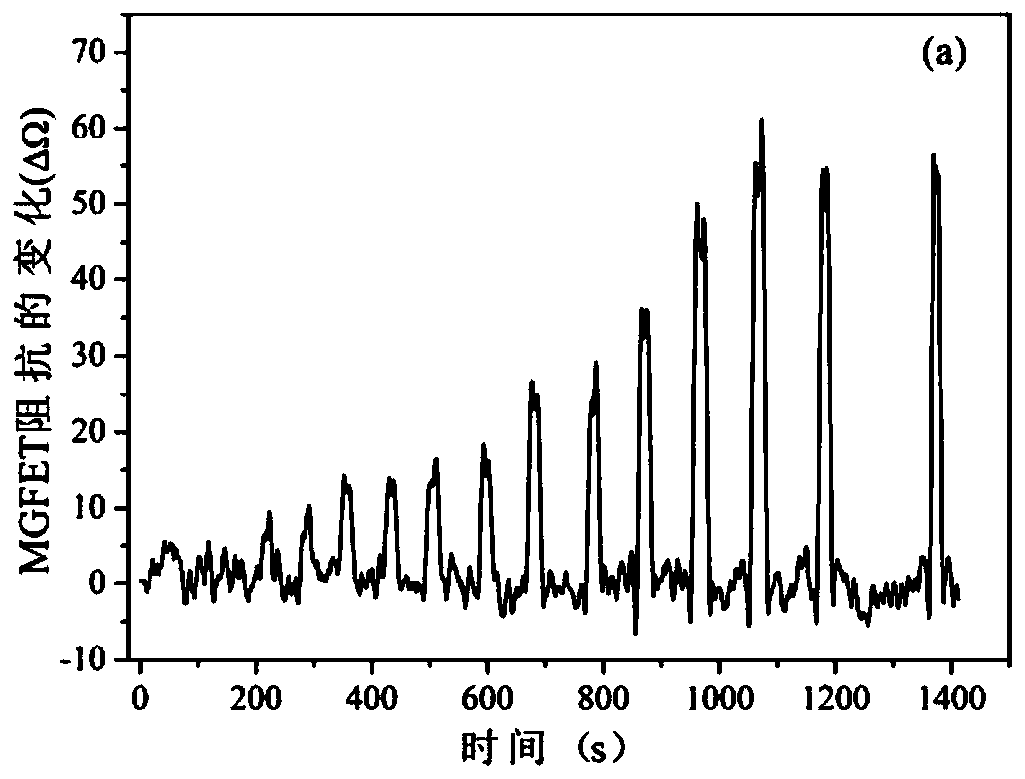

The invention proposes a magnetic control graphene field effect transistor sensor, and a manufacturing method, a measuring method and a detecting method thereof. The manufacturing method comprises thesteps of: transferring graphene onto a glass plate provided with indium tin oxide electrodes as a channel between the two electrodes; using a reaction chamber which is made of a glass material and adhered on the surface of a graphene film as a sample cell for accommodating an electrolyte; injecting PBASE dissolved in dimethyl sulfoxide DMSO into the sample cell, keeping the liquid for a set timeat room temperature, so that the PBASE completely reacts with the graphene, and removing the unreacted PBASE; introducing a probe aptamer into MGFET, and incubating the probe aptamer with the PBASE for a set time at room temperature, so that the probe aptamer fully reacts with the PBASE, and removing the unreacted probe aptamer; and adding a conjugate of magnetic nanoparticles and complementary DNA into the MGFET for a set time, so that the complementary DNA and the probe aptamer are completely combined. The resistance of the magnetic control graphene field effect transistor sensor is modulated by means of a magnetic field serving as a back gate, the impedance thereof changes with the intensity of the magnetic field, and the magnetic control graphene field effect transistor sensor exhibitsgood sensitivity.

Description

technical field The disclosure relates to the technical field of analytical chemistry, in particular to a magnetron graphene field-effect tube sensor and its fabrication, measurement and detection methods. Background technique Currently, there are a variety of biosensors for the detection of biomolecules, including fluorescent biosensors, electrochemical biosensors, and field-effect transistor biosensors. Among them, field-effect transistor biosensors have attracted extensive attention due to their high sensitivity and specificity. Field-effect transistors based on nanomaterials have been widely used in biosensors, including one-dimensional silicon nanowires, carbon nanotubes, and two-dimensional graphene. Graphene is a two-dimensional material with a single-layer sheet structure composed of carbon atoms. Due to its high specific surface area, high electrical conductivity, and excellent electron mobility at room temperature, these unique properties of graphene can be used...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): G01N27/414

CPCG01N27/4145G01N27/4146

Inventor 岳伟伟孙锦锦谢晓慧张德帅焦锡檬张超

Owner SHANDONG NORMAL UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com