Intelligent automatic control system of mine gas chromatograph and control method

A technology of automatic control system and gas chromatograph, which is applied to instruments, scientific instruments, measuring devices, etc., can solve the problems of a large number of gas bulbs, the gas analysis work of laboratory analysts, improve work efficiency, etc., and achieve stable startup. It has the effect of cooling off with shutdown, solving the problem of long waiting time, and saving waiting time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

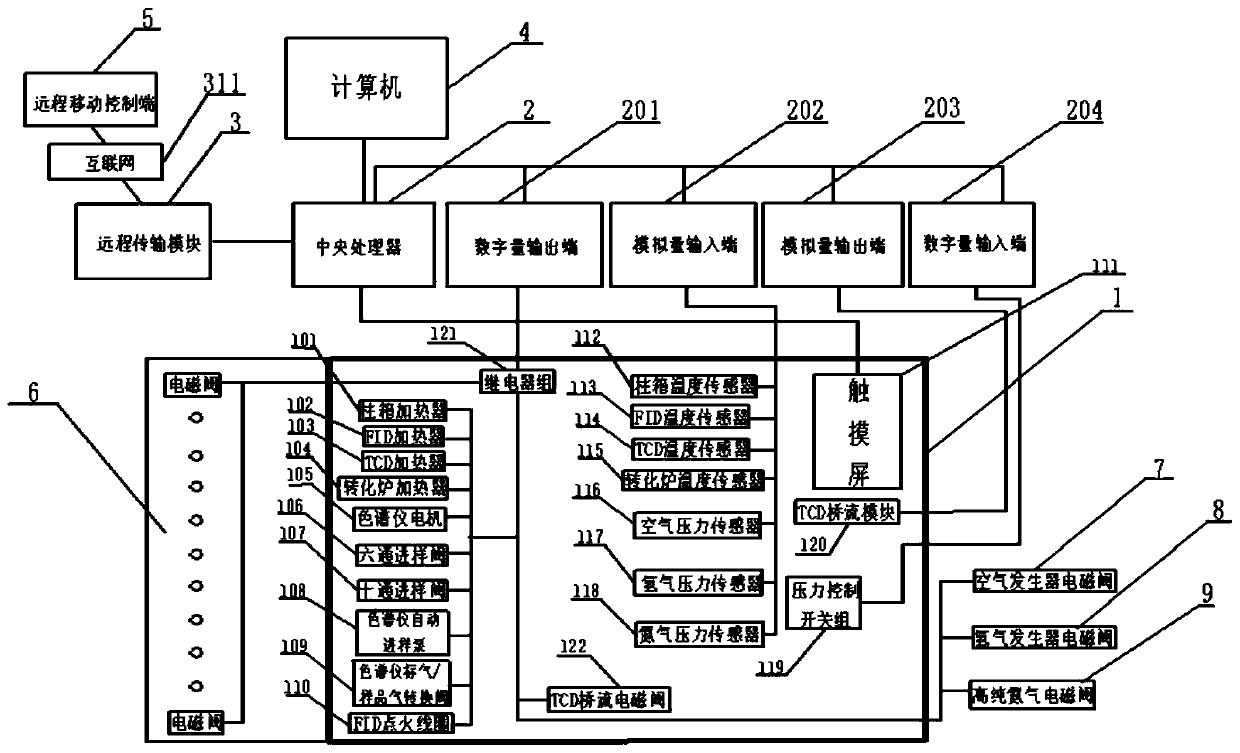

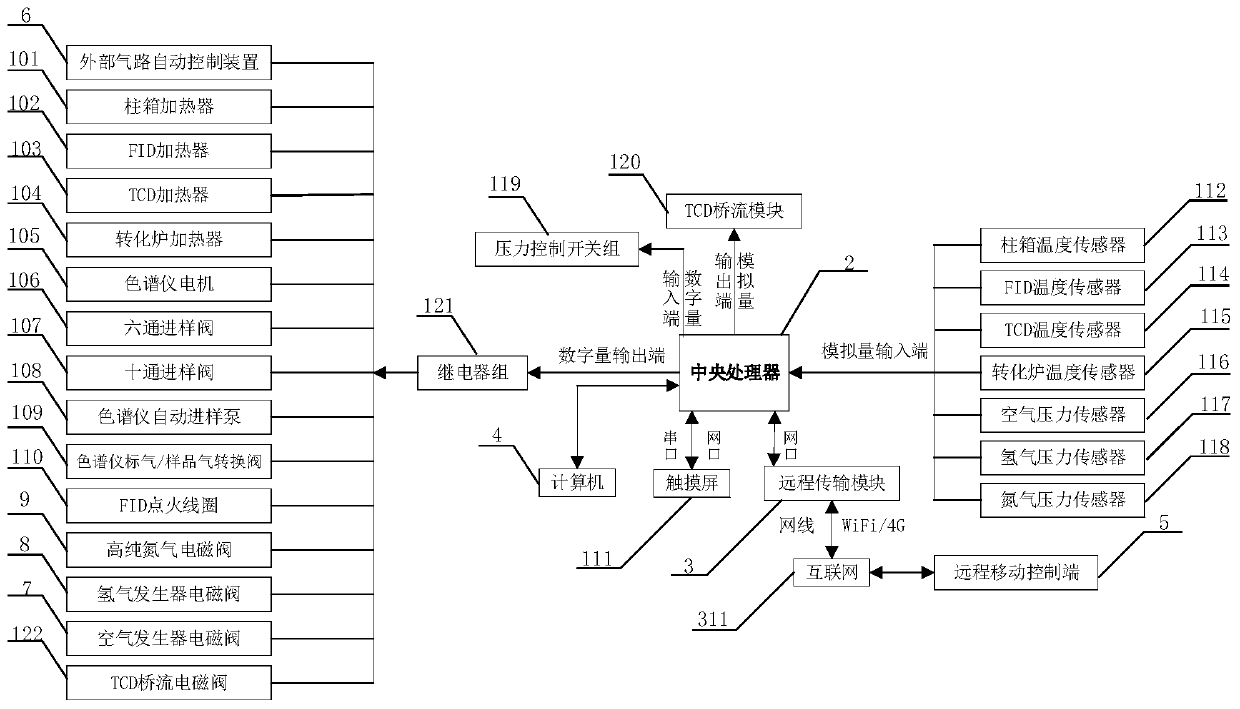

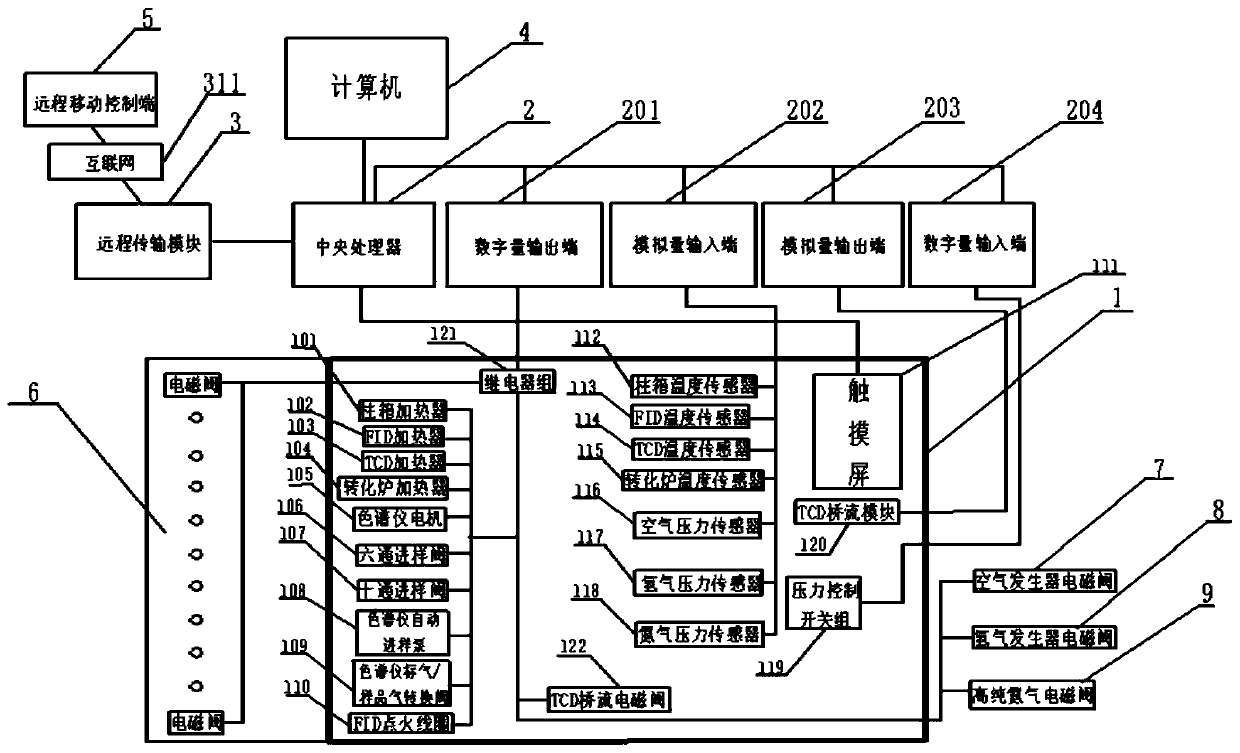

[0019] For a first example, see figure 1 , figure 2 , the technical solution adopted by the present invention to solve its technical problems is: an intelligent automatic control system of a gas chromatograph for mines, which mainly includes a central processing unit 2 as the core, and the central processing unit 2 is electrically connected to a computer 4 and a digital output respectively. Terminal 201, analog input terminal 202, analog output terminal 203, digital input terminal 204, touch screen 111 on the mining gas chromatograph 1, and digital output terminal 201 are respectively electrically connected to the external gas circuit automatic control device through the relay group 121 Solenoid valve on 6, four heaters, chromatograph motor 105, six-port sampling valve 106, ten-port sampling valve 107, chromatograph automatic sampling pump 108, FID ignition coil 110, TCD bridge flow solenoid valve 122, Three types of gas generator solenoid valves, the analog input end 202 is...

no. 2 example

[0023] For a second embodiment, see figure 1 , figure 2 , the technical solution adopted by the present invention to solve its technical problems is: an intelligent automatic control system of a gas chromatograph for mines, which mainly includes a central processing unit 2 as the core, and the central processing unit 2 is electrically connected to a computer 4 and a digital output respectively. Terminal 201, analog input terminal 202, analog output terminal 203, digital input terminal 204, touch screen 111 on the mining gas chromatograph 1, and digital output terminal 201 are respectively electrically connected to the external gas circuit automatic control device through the relay group 121 Solenoid valve on 6, four heaters, chromatograph motor 105, six-port sampling valve 106, ten-port sampling valve 107, chromatograph automatic sampling pump 108, FID ignition coil 110, TCD bridge flow solenoid valve 122, Three types of gas generator solenoid valves, the analog input end 20...

no. 3 example

[0028] For a third embodiment, see figure 1 , figure 2 , a control method for an intelligent automatic control system of a mining gas chromatograph, comprising ① clicking on the remote mobile control terminal 5 to turn on the main power supply, and opening three kinds of gas generator solenoid valves (air generator solenoid valve 7, hydrogen generator Electromagnetic valve 8, high-purity nitrogen electromagnetic valve 9), the outlet pressure of the gas generator reaches the pressure rating of the pressure control switch group 119, the pressure control switch group 119 is opened, and the temperature of the column oven temperature sensor 112 is T 1 , FID temperature sensor 113 temperature is T 2 , TCD temperature sensor 114 temperature is T 3 , the temperature of the reformer temperature sensor 115 is T 4 , when 100℃≥T 1 >0°C and 200°C≥T 2 >0°C and 200°C≥T 3 >0°C and 400°C≥T 4 When >0°C, the remote mobile control terminal 5 shows that the mining gas chromatograph 1 can b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com