VTK-based robot free-form surface workpiece polishing offline programming method

An offline programming, surface workpiece technology, applied in comprehensive factory control, instruments, simulators, etc., can solve the problems of relying on external import of grinding point data, unclear selection of grinding point spline curves, and poor human-computer interaction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0096] In order to verify the specific implementation of the present invention, an experiment was carried out using a grinding system constructed by Guangzhou CNC GSK_RB20 six-degree-of-freedom industrial robot and an abrasive belt machine. The holding device is installed at the end of the industrial robot, and the industrial robot drives the workpiece to be ground on the working surface of the grinding wheel of the abrasive belt machine. The unit of each coordinate data shown below is mm.

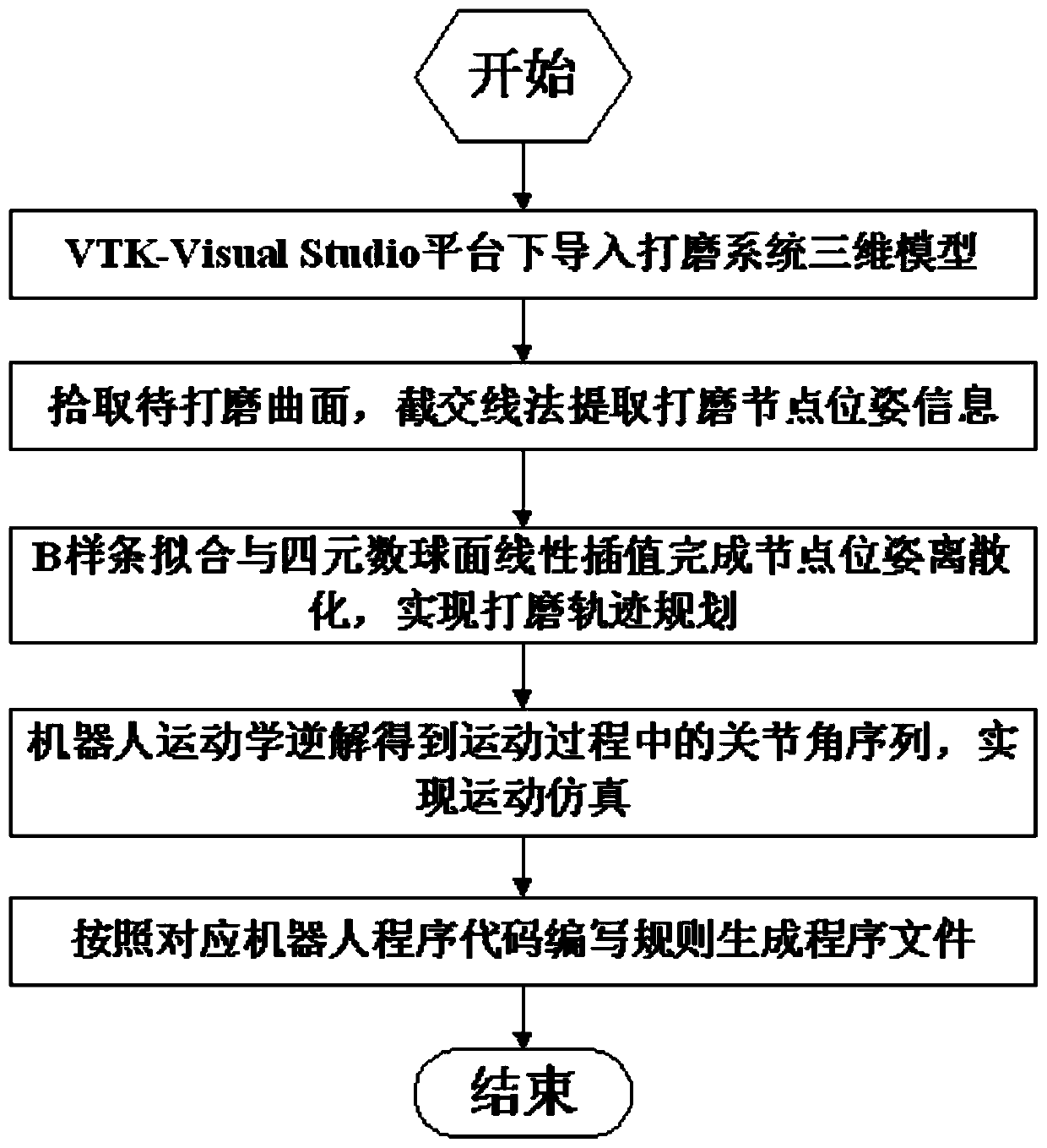

[0097] According to attached figure 1 Described implementation step flow chart, implementation steps are as follows:

[0098] Step (1): Import the 3D model of the grinding system and lay it out in the offline programming environment. In order to complete the layout, the robot, the belt machine and the workpiece are calibrated according to the actual pose relationship between the workpiece and the tool, and according to the calibration results:

[0099] The position and attitude relation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com