Flame combustion state detection method

A flame combustion state and detection method technology, applied in the direction of instruments, calculations, character and pattern recognition, etc., can solve the problems of less flame information, increase the difficulty of flame combustion judgment, and not suitable for direct observation, so as to achieve enhanced safety and reliability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

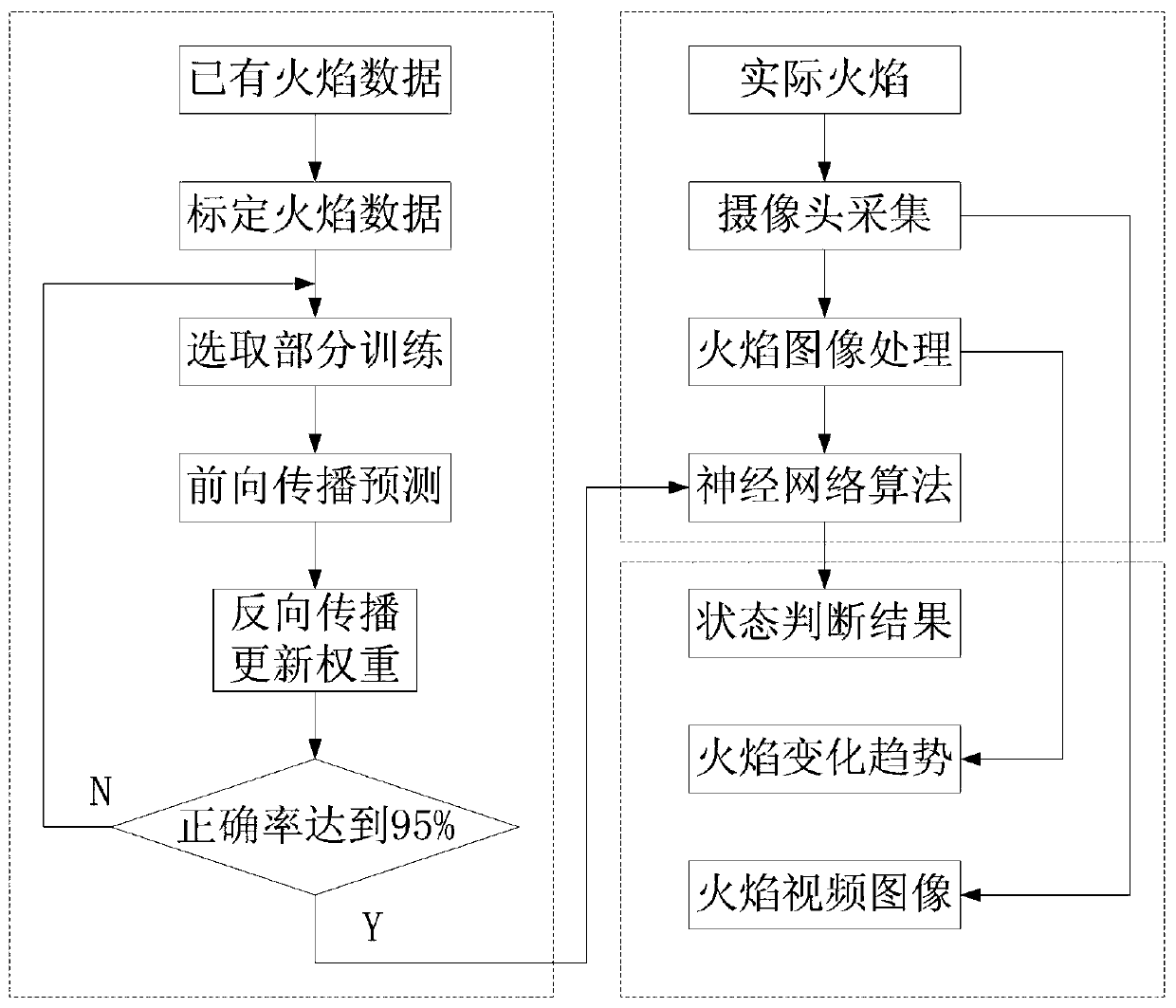

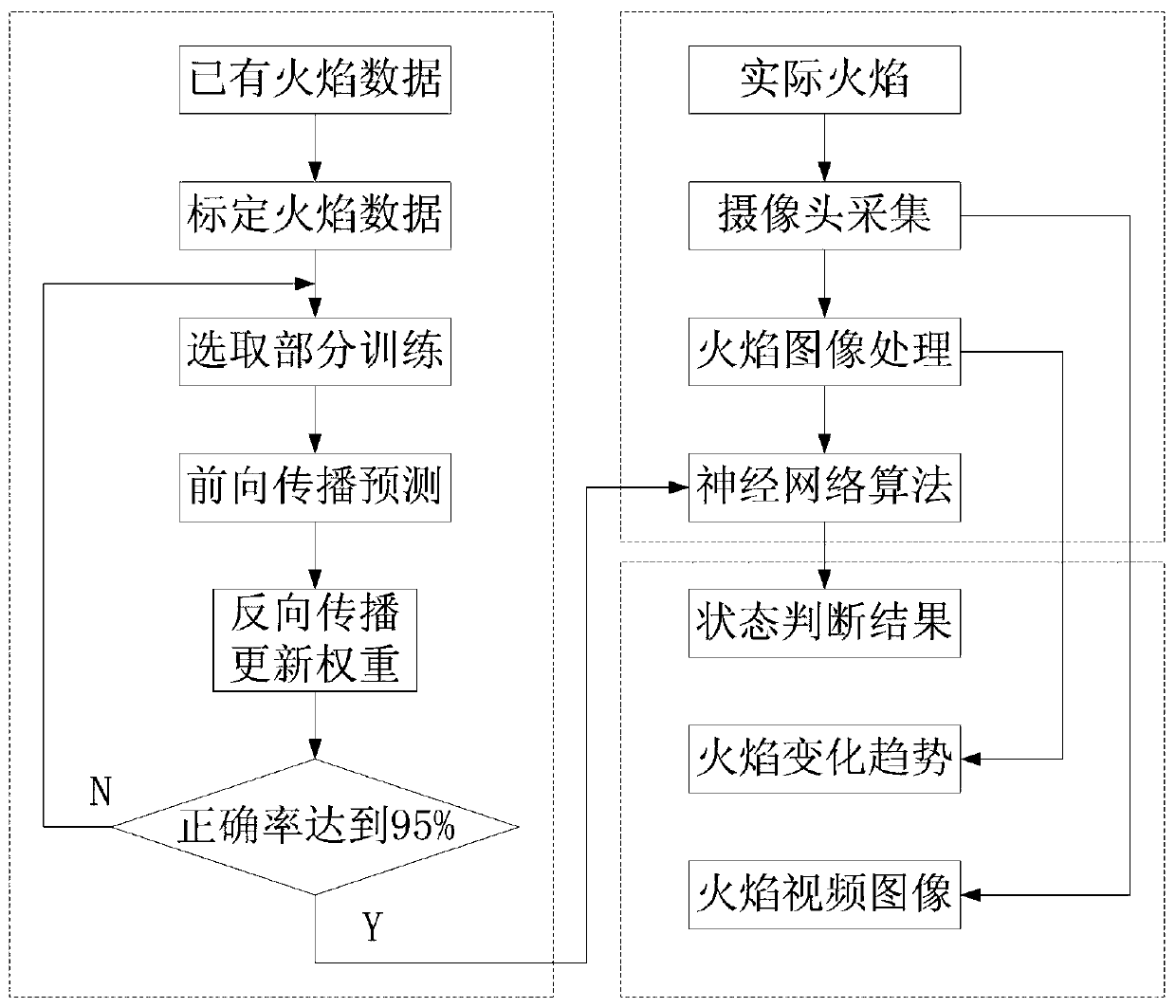

[0027] A flame combustion state detection method specifically comprises the following steps:

[0028] First, extract a continuous flame video of the whole process from ignition to normal combustion to extinguishment, and preprocess the image information of the extracted view to extract the flame area feature; use the flame area feature as the basis for the identification of the flame combustion state, because the flame video It is composed of a group of continuous flame pictures, forming a set of three-dimensional matrix, and the amount of data is much larger than that of a single flame picture. Therefore, compared with the flame features of a picture, the information feature has a large amount of information, a large amount of features, continuous feature information, and real-time performance. Good features, so the recognition is accurate a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com