Food processing methods for reducing allergenicity of crayfish

A technology for food processing and allergens, applied in the fields of food ingredients containing natural extracts, food science, etc., to achieve the effect of reducing allergenicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

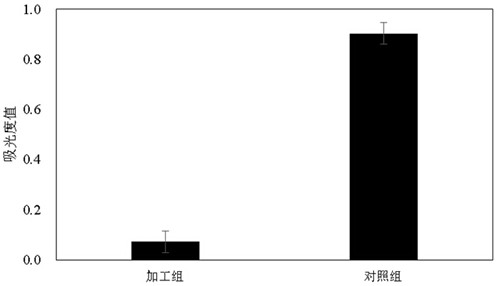

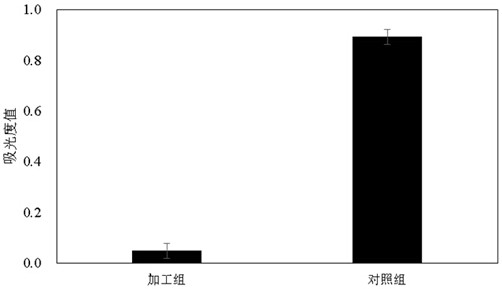

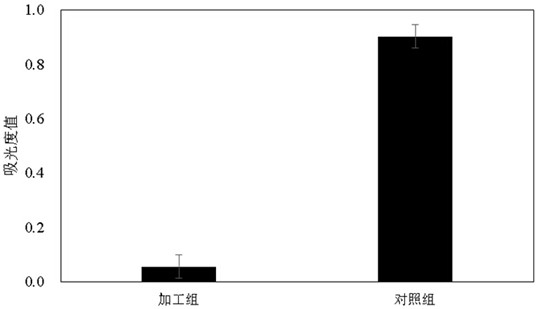

Image

Examples

Embodiment approach 1

[0020] This embodiment provides a food processing method for reducing the allergenicity of crayfish: comprising the following steps:

[0021] S1: Raw material processing: Shell the commercially available crayfish first, remove the head and tail, prick holes in the crayfish meat with a thin bamboo stick, and add sugar prepared by white sugar and sucrose in a mass ratio of 1:1 Soak in 15% sugar solution for 10 minutes, remove, drain, and set aside.

[0022] S2: Preparation of fermentation strains: culture lactic acid bacteria and Saccharomyces cerevisiae to form a composite flora with a bacterial liquid volume ratio of 3:1; Composition, the volume ratio of the three bacterial liquids is 2:1:1;

[0023] S3: Inoculate the prepared composite flora onto the conditioned crayfish meat, and ferment in a closed container at 30°C-35°C for 72 hours, with an inoculation amount of 4%;

[0024] S4: After the fermentation is over, add the post-conditioning solution to the crayfish meat, sti...

Embodiment approach 2

[0026] This embodiment provides a food processing method for reducing the allergenicity of crayfish: comprising the following steps:

[0027] S1: Raw material processing: Shell the commercially available crayfish first, remove the head and tail, pierce holes in the crayfish meat with thin bamboo sticks, and add sugar prepared by white granulated sugar and sucrose in a mass ratio of 1:2 Soak in 15% sugar solution for 5 minutes, remove, drain, and set aside.

[0028] S2: Preparation of fermentation strains: culture lactic acid bacteria and Saccharomyces cerevisiae to form a composite flora with a bacterial liquid volume ratio of 3:1; Composition, the volume ratio of the three bacterial liquids is 2:1:1;

[0029] S3: Inoculate the prepared composite flora onto the conditioned crayfish meat, and ferment in a closed container at 30°C-35°C for 48 hours, with an inoculation amount of 5%;

[0030] S4: After the fermentation is over, add the post-conditioning solution to the crayfish...

Embodiment approach 3

[0032] This embodiment provides a food processing method for reducing the allergenicity of crayfish: comprising the following steps:

[0033] S1: Raw material processing: Shell the commercially available crayfish first, remove the head and tail, pierce holes in the crayfish meat with a thin bamboo stick, and add sugar prepared by white sugar and sucrose at a mass ratio of 1:1.5 Soak in 15% sugar solution for 8 minutes, remove, drain, and set aside.

[0034] S2: Preparation of fermentation strains: culture lactic acid bacteria and Saccharomyces cerevisiae to form a composite flora with a bacterial liquid volume ratio of 3:1; Composition, the volume ratio of the three bacterial liquids is 2:1:1;

[0035]S3: Inoculate the prepared composite flora onto the conditioned crayfish meat, and ferment in a closed manner at 30°C-35°C for 24 hours, with an inoculation amount of 3%;

[0036] S4: After the fermentation is over, add the post-conditioning solution to the crayfish meat, stir ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com