Preparation method of royal jelly polypeptide

A technology of royal jelly and mixed liquid, which is applied in fermentation and other directions, can solve the problems of poor palatability, sour taste of royal jelly, etc., and achieve the effects of increasing content, strong anti-oxidation ability of oil, and facilitating release

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

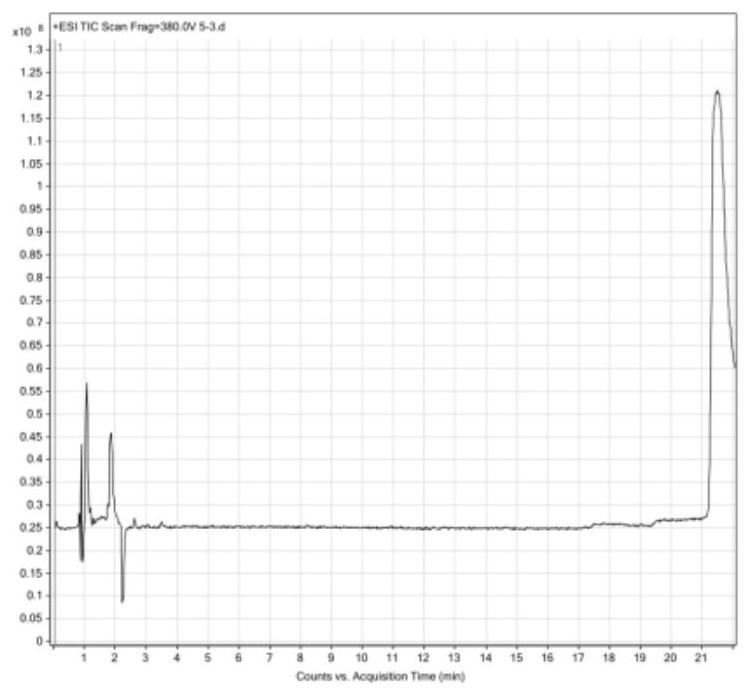

Image

Examples

Embodiment 1

[0035] A royal jelly polypeptide, comprising the following raw material components:

[0036] Royal jelly, deionized water, edible citric acid, edible pepsin, edible calcium hydroxide, edible papain.

[0037] A preparation method of royal jelly polypeptide, comprising the following steps:

[0038] Step 1: Add deionized water into the royal jelly, mix the royal jelly and deionized water according to the mass ratio of 1:8, stir and mix well to obtain the mixed solution A;

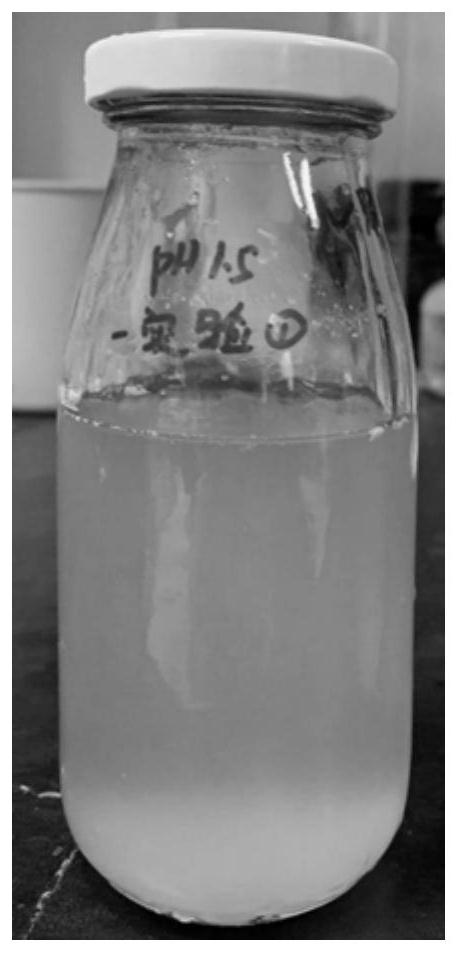

[0039] Step 2: Adjust the mixed solution A obtained in Step 1 to pH 1.5 with edible citric acid;

[0040] Step 3: Add 5% edible pepsin into the mixed solution A in step 2 according to the mass of royal jelly, and mix well to obtain the mixed solution B;

[0041] Step 4: Put the mixture B obtained in step 3 at 37°C for constant temperature enzymolysis, and the time for constant temperature enzymolysis is 7 hours to obtain hydrolyzate C;

[0042] Step 5: Adjust the pH value of the hydrolyzate C in step 4 to 7...

Embodiment 2

[0047] A royal jelly polypeptide, comprising the following raw material components:

[0048] Royal jelly, deionized water, edible citric acid, edible pepsin, edible calcium hydroxide, edible papain.

[0049] A preparation method of royal jelly polypeptide, comprising the following steps:

[0050] Step 1: Add deionized water into royal jelly, mix royal jelly and deionized water according to the mass ratio of 1:10, stir and mix well to obtain mixed solution A;

[0051] Step 2: Adjust the mixed solution A obtained in Step 1 to pH 1.5 with edible citric acid;

[0052] Step 3: Add 5% edible pepsin into the mixed solution A in step 2 according to the mass of royal jelly, and mix well to obtain the mixed solution B;

[0053] Step 4: Put the mixture B obtained in step 3 at 37°C for constant temperature enzymolysis, and the time for constant temperature enzymolysis is 7 hours to obtain hydrolyzate C;

[0054] Step 5: Adjust the pH value of the hydrolyzate C in step 4 to 7.0 with edi...

Embodiment 3

[0059] A royal jelly polypeptide, comprising the following raw material components:

[0060] Royal jelly, deionized water, edible citric acid, edible pepsin, edible calcium hydroxide, edible papain.

[0061] A preparation method of royal jelly polypeptide, comprising the following steps:

[0062]Step 1: Add deionized water into royal jelly, mix royal jelly and deionized water according to the mass ratio of 1:12, stir and mix well to obtain mixed liquid A;

[0063] Step 2: Adjust the mixed solution A obtained in Step 1 to pH 1.5 with edible citric acid;

[0064] Step 3: Add 5% edible pepsin into the mixed solution A in step 2 according to the mass of royal jelly, and mix well to obtain the mixed solution B;

[0065] Step 4: Put the combined solution B obtained in step 3 at 37°C for constant temperature enzymolysis, and the time for constant temperature enzymolysis is 8 hours to obtain hydrolyzate C;

[0066] Step 5: Adjust the pH value of the hydrolyzate C in step 4 to 7.0 w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com