PVC material roll-cutting device for blister packaging machine

A blister packaging and machine-used technology, applied in packaging, metal processing, etc., can solve the problems of replacing the whole machine and achieve high precision, safe operation, convenient and quick operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The following description is merely exemplary in nature and not intended to limit the disclosure, application or use. The specific implementation of the PVC rolling cutting device for the blister packaging machine of the present invention will be further described below in conjunction with the accompanying drawings.

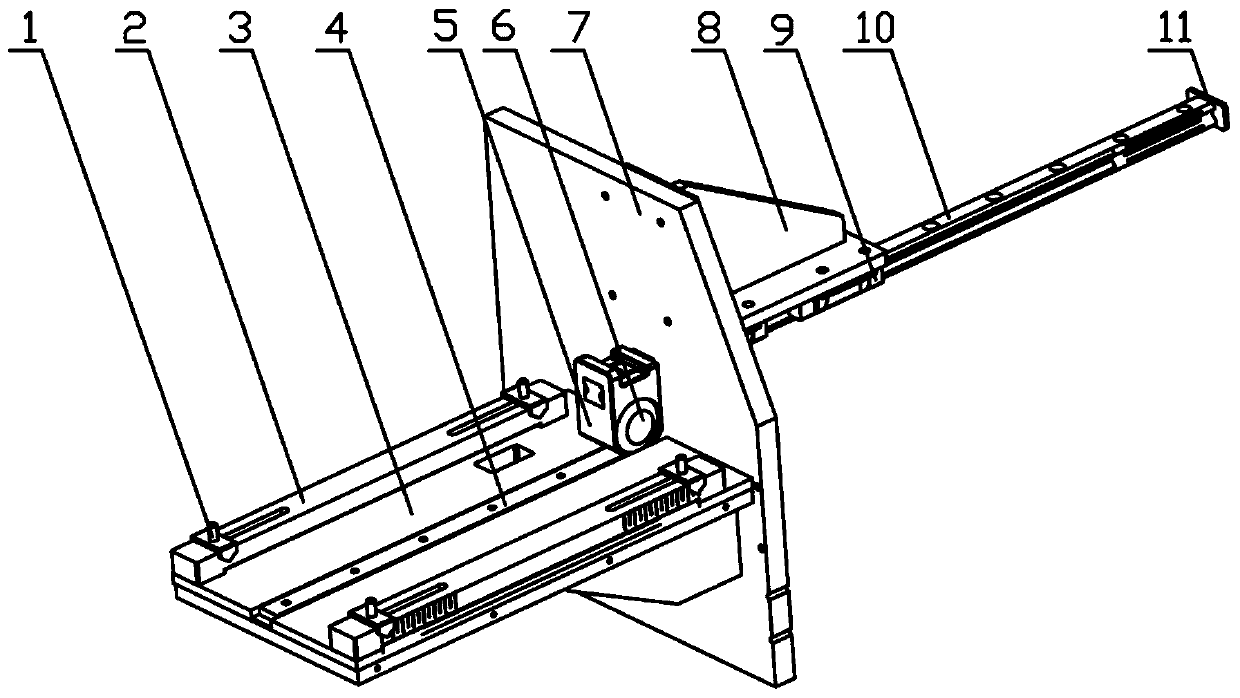

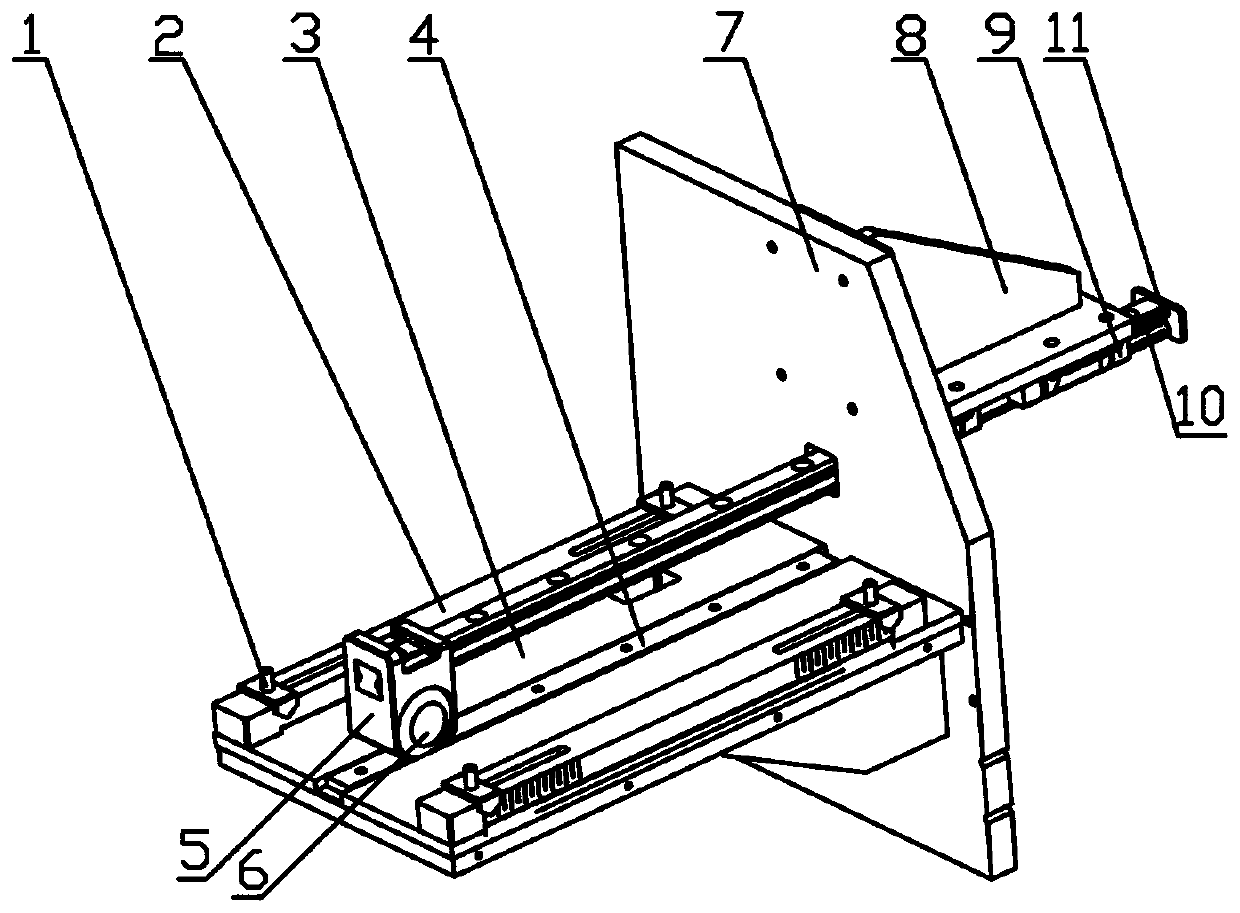

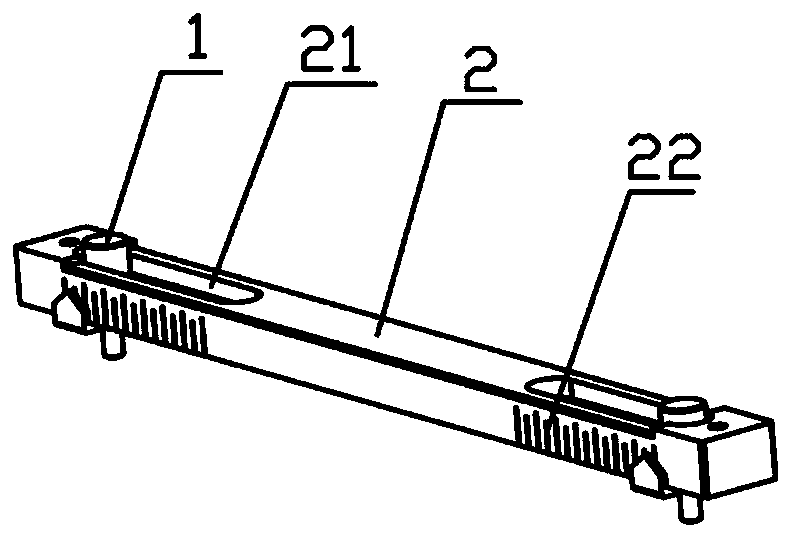

[0030] like figure 1 , figure 2 Shown is a schematic structural view of a preferred embodiment of the PVC rolling cutting device for the blister packaging machine according to the present invention. A PVC roller cutting material cutting device for a blister packaging machine of the present invention comprises a group of PVC bead 2, a manual cutter seat 3 and a roller cutter 6, and the roller cutter 6 is fixed on the side of the cutter holder 5; The cutter seat 5 is fixed on one end of the guide rail 10; the cutter seat 5 is provided with a magnet, and the cutter seat 5 is adsorbed on the forming wallboard 7 by the magnet. The material cutting device of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com