A system and method for purifying dirt in a circulating pool and online cleaning sludge at the bottom of the pool

A technology of circulating water pool and circulating water, applied in chemical instruments and methods, water/sludge/sewage treatment, sludge treatment, etc., can solve the problems of affecting the cooling efficiency of the circulating water system, wasting water resources, secondary pollution, etc. Achieve the effect of maintaining long-term stable operation, cost-effective, and rapid assembly design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

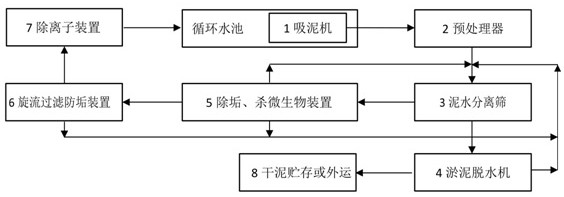

[0064] Such as figure 1 As shown, a circulating pool dirt purification and pool bottom sludge online cleaning system includes a dredge suction machine 1, a preprocessor 2, a mud-water separation screen 3, a sludge dehydrator 4, a descaling and microbial killing device 5, a cyclone filter Scale device 6 and deionization device 7;

[0065] The dredger 1 is used to absorb the sludge at the bottom of the pond;

[0066] In an embodiment, the dredge 1 includes a dredge pump, a dredge pan, a pipeline, a float, and a moving and positioning system.

[0067] The key component is the mud suction plate, which can not only suck out the soft mud, but also break and suck out the hard mud that has been scarred. The path efficiently and evenly absorbs the silt at the bottom of the pool, avoiding that some places cannot be sucked, and some places are repeatedly sucked.

[0068] The float should also have the function of self-moving and positioning, because it is online and fully automatic to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com