Fireproof building curtain wall material and preparation method thereof

A curtain wall and refractory technology, which is applied in the field of refractory building curtain wall materials and its preparation, can solve the problems of not being able to realize the integration of ball milling and drying well, not having a good flame retardant effect, and the influence of its own strength, so as to achieve improvement Stirring efficiency and stirring quality, good rotation performance, and the effect of improving the overall stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

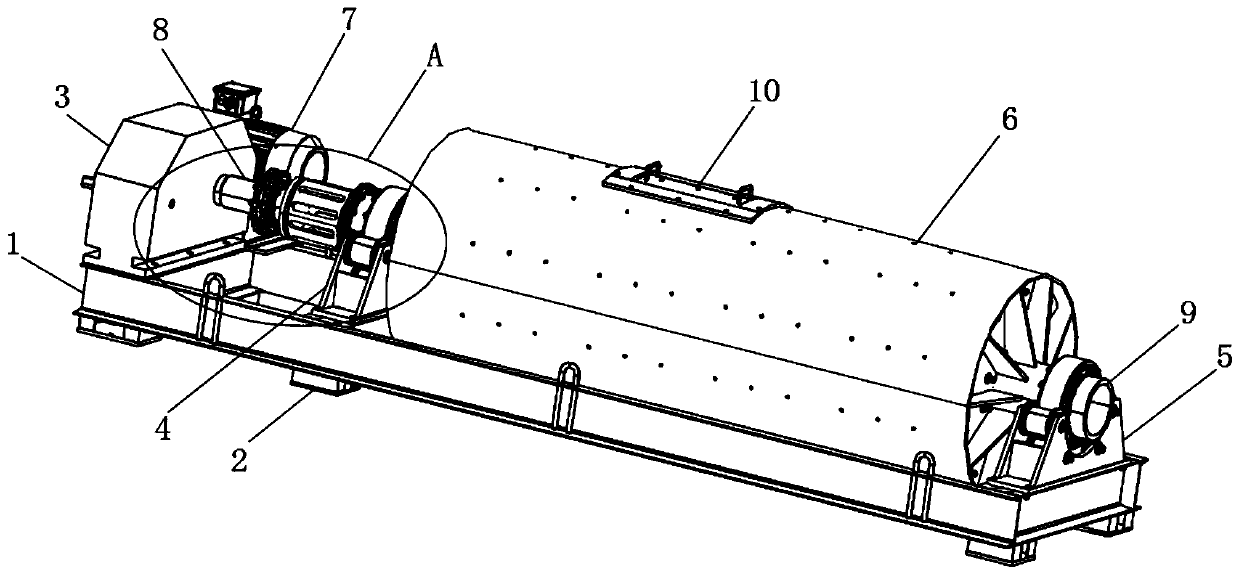

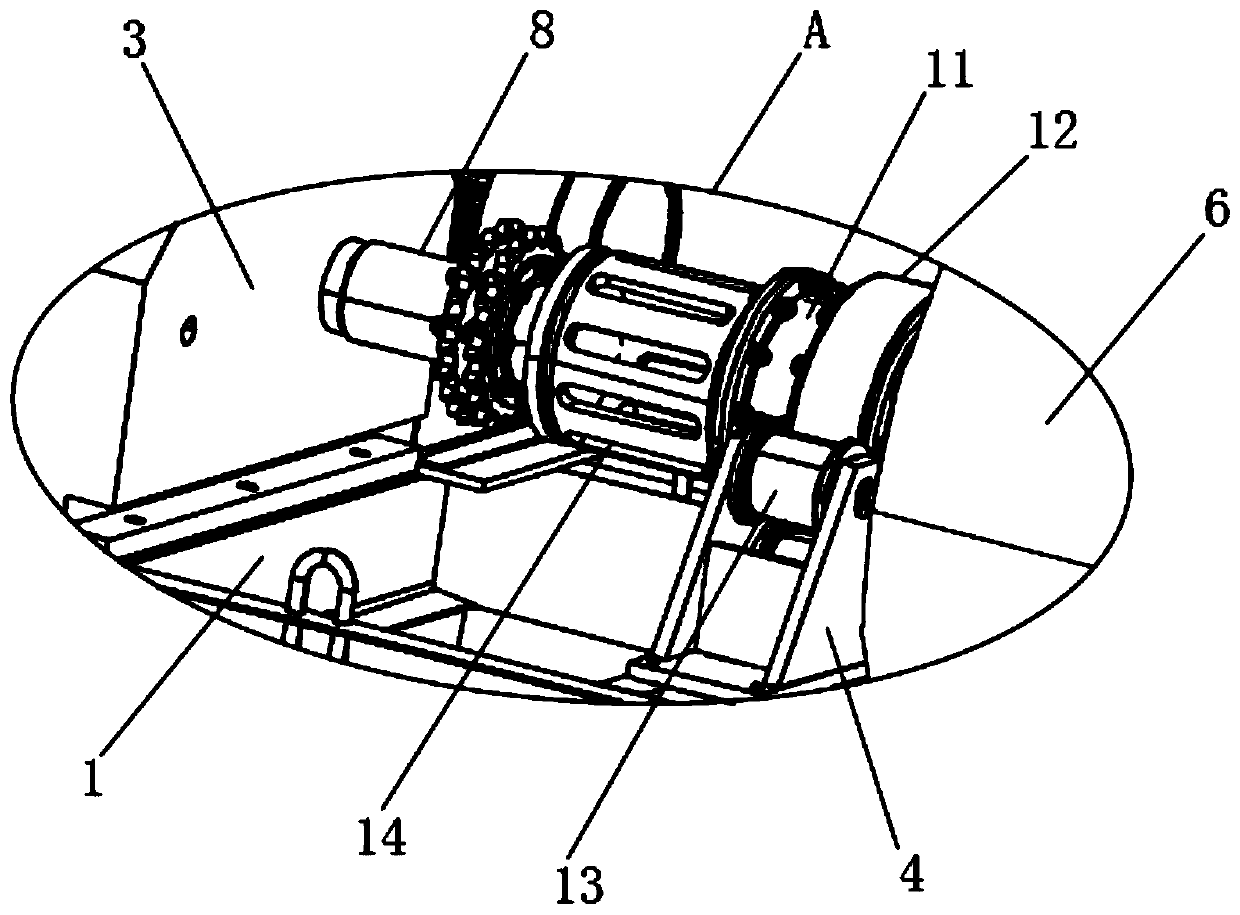

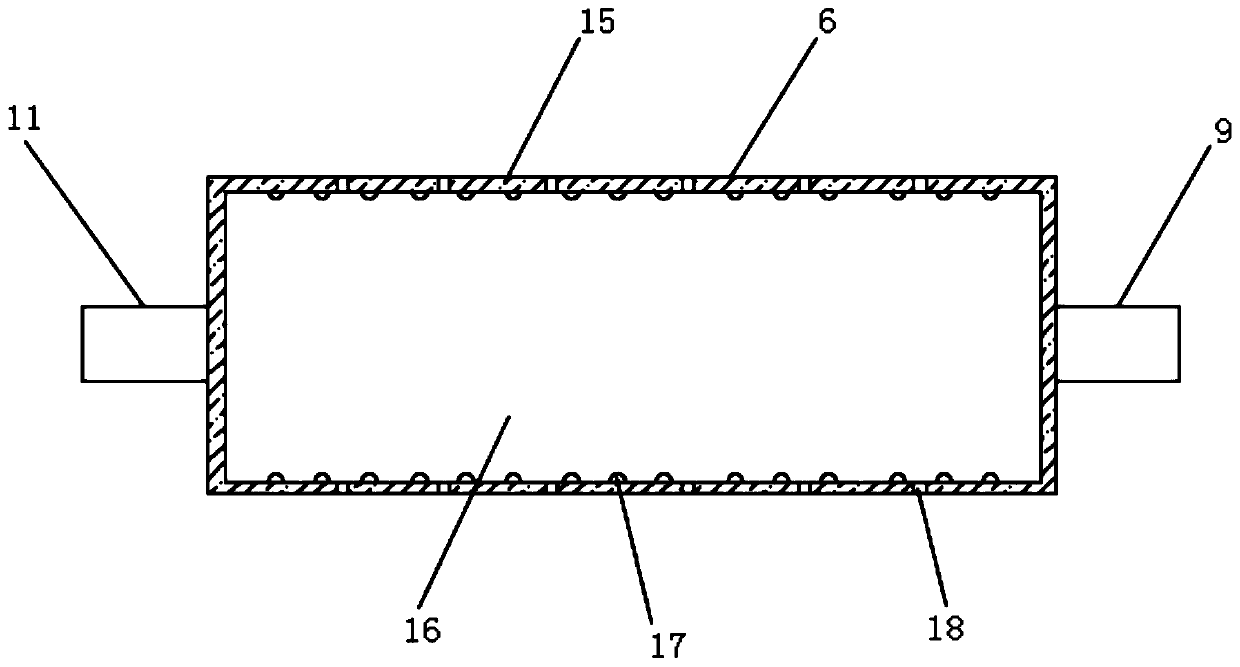

Method used

Image

Examples

Embodiment 1

[0035]A refractory building curtain wall material, the building curtain wall material is composed of the following components by weight ratio: 4 parts of zinc oxide, 10 parts of limestone, 11 parts of quartz sand, 6 parts of soda ash, 3 parts of boric acid, 4 parts of cosolvent, polyacrylonitrile 8 parts of fiber, 11 parts of mineral wool and 15 parts of semi-siliceous clay;

[0036] The specific operation steps of the preparation method of the building curtain wall material are as follows:

[0037] Step 1. Mixing: Take the building curtain wall materials according to the above weight ratios: 4 parts of zinc oxide, 10 parts of limestone, 11 parts of quartz sand, 6 parts of soda ash and 3 parts of boric acid. At room temperature, put the above raw materials in the mixer Internally mix evenly, simultaneously carry out pretreatment to weight ratio being 8 parts of polyacrylonitrile fibers;

[0038] Step 2, ball milling: after mixing, the mixed raw materials are ball milled with ...

Embodiment 2

[0045] A refractory building curtain wall material, the building curtain wall material is composed of the following components by weight ratio: 4 parts of zinc oxide, 10 parts of limestone, 11 parts of quartz sand, 6 parts of soda ash, 3 parts of boric acid, 4 parts of cosolvent, 11 parts of mineral wool part and 15 parts of semi-siliceous clay, the operating steps of difference and embodiment one are as follows:

[0046] Step 1. Mixing: Take the building curtain wall materials according to the above weight ratios: 4 parts of zinc oxide, 10 parts of limestone, 11 parts of quartz sand, 6 parts of soda ash and 3 parts of boric acid. At room temperature, put the above raw materials in the mixer Mix evenly inside;

[0047] Other operating steps are the same as in Embodiment 1.

Embodiment 3

[0049] A refractory building curtain wall material, the building curtain wall material is composed of the following components by weight ratio: 4 parts of zinc oxide, 10 parts of limestone, 11 parts of quartz sand, 6 parts of soda ash, 3 parts of boric acid, 4 parts of cosolvent, polyacrylonitrile 8 parts of fiber, 15 parts of semi-siliceous clay, difference and the operating steps of embodiment one are as follows:

[0050] Step 2, ball milling: after mixing, the mixed raw materials are ball milled with a small ball mill, and at the same time, 15 parts of the semi-siliceous clay are ball milled, and dried after the ball milling is completed;

[0051] Step 3, melting: put the dried mixed raw materials in the crucible kiln, then add 8 parts of pretreated polyacrylonitrile fibers and 15 parts of semi-siliceous clay in sequence, and add 4 parts of co-solvent, first put the crucible kiln Heat to 400-550°C, stay for 2.5 hours and continue to heat to 800-950°C, then stay for 2.5 hour...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com