Voltage-transformation type softening dripping performance testing method and equipment

A test method and test equipment technology, applied in the direction of measuring device, flow characteristics, investigation stage/state change, etc., can solve the problems that the actual situation inside the blast furnace cannot be objectively displayed, the production situation of the blast furnace does not match, etc., and achieve accurate program control and data collection , the effect of improving accuracy and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058] Embodiment 1: a kind of variable pressure type reflow dripping performance test method, comprises the following steps:

[0059] S100: sample preparation: take the experimental samples iron-containing charge and coke required for the experiment respectively, and place the iron-containing charge and the coke in a drying oven to dry;

[0060] As an improvement, the particle size of the iron-containing charge and coke weighed in the S100 is 10-12.5mm, the mass of the iron charge and the coke are 500g respectively, and the drying temperature of the drying oven is 100±10°C. The mass of coke is 500g, and the error is ±1 grain.

[0061] S200: sample loading: add dried coke to the pre-prepared graphite crucible, and apply pressure evenly, the coke layer is the lower coke layer, test the thickness of the lower coke layer; Add the dried iron-containing charge, and apply pressure evenly to test the thickness of the iron-containing charge; then add some coke to the surface of the i...

Embodiment 2

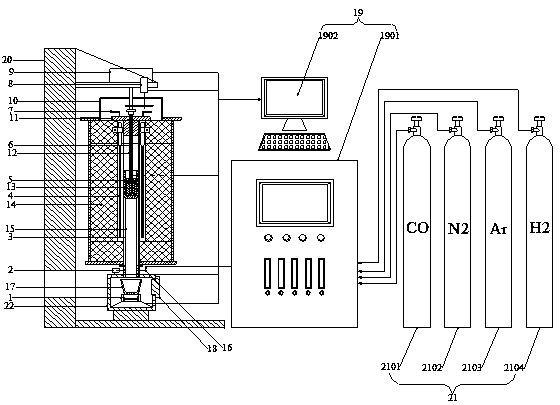

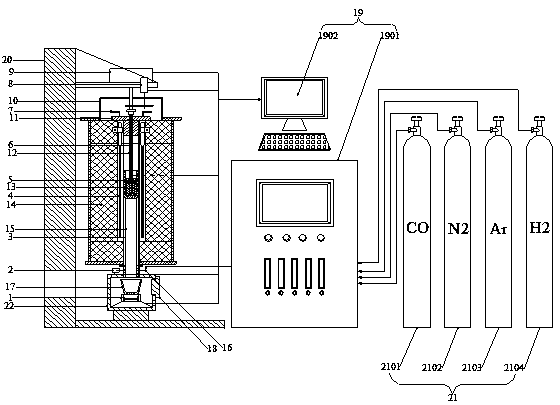

[0076] Embodiment 2: as figure 1 As shown, a pressure-variable reflow dripping performance testing equipment, the pressure-variable reflow dripping performance testing equipment includes a support frame 20, a pressurizing device 9, a melting furnace body 14, a collecting device 22, a gas supply system 21 and control system 19;

[0077] Support frame 20: the section of the support frame 20 is an L-shaped structure;

[0078] Droplet furnace body 14: the droplet furnace body 14 is arranged on one side of the support frame 20;

[0079]The top of the droplet furnace body 14 is provided with an exhaust hood 10, and at the top of the droplet furnace body 14 and inside the exhaust hood 10, a heat insulating collar 11 is arranged. The 14 furnace chambers of the drop furnace body are coaxially arranged;

[0080] Specifically, the diameter of the furnace body 14 of the droplet furnace is 100 mm.

[0081] The furnace body 14 of the droplet furnace is provided with a graphite branch pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com