Volatile grain mould preventing sustained release tablet and preparation method thereof

A volatile, sustained-release tablet technology, applied in the fields of botanical equipment and methods, food preservation, food science, etc., can solve major safety problems, ecological environment pollution, food toxicity residues and other problems, and achieve low residues and safety. High resistance, the effect of preventing grain mildew

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

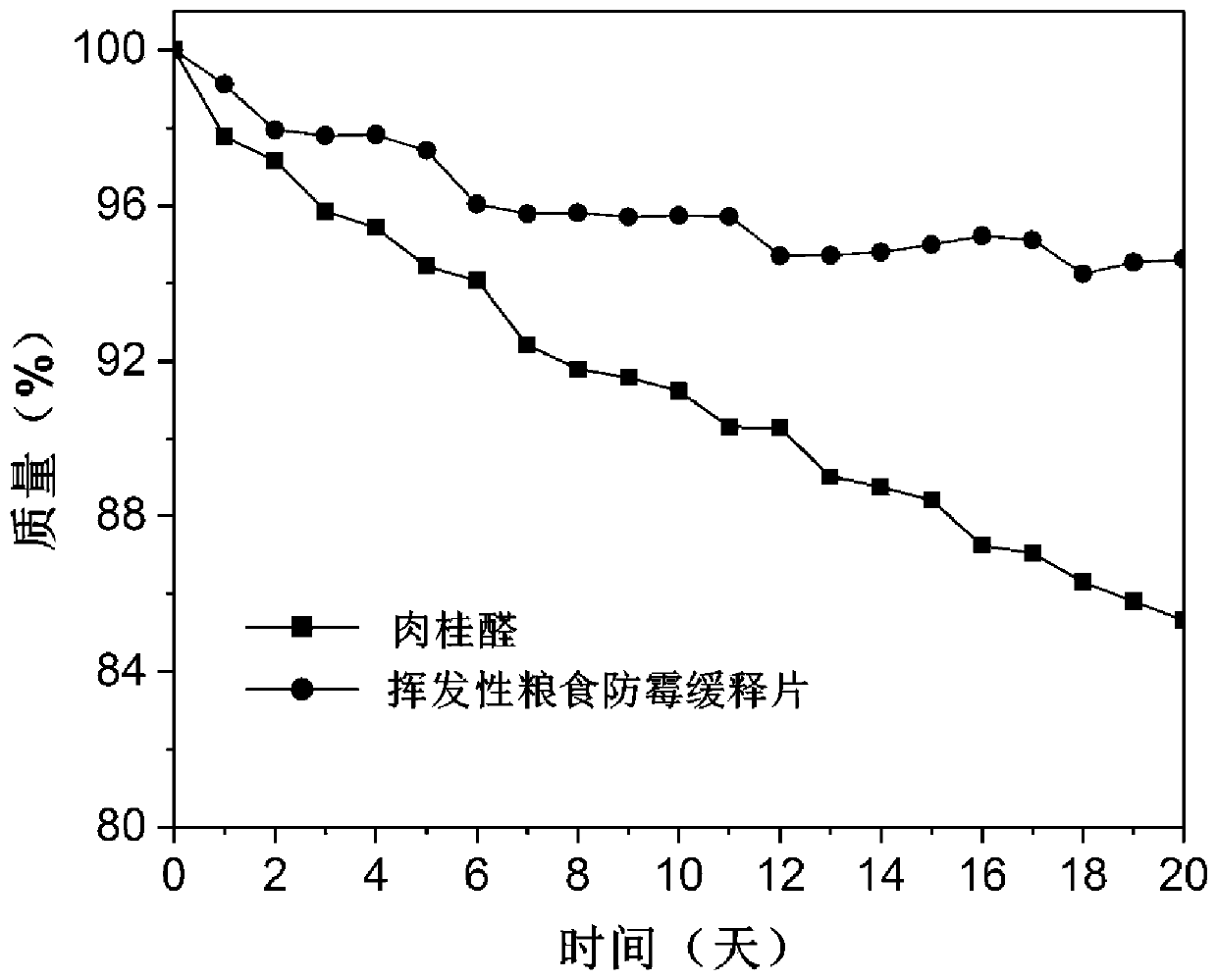

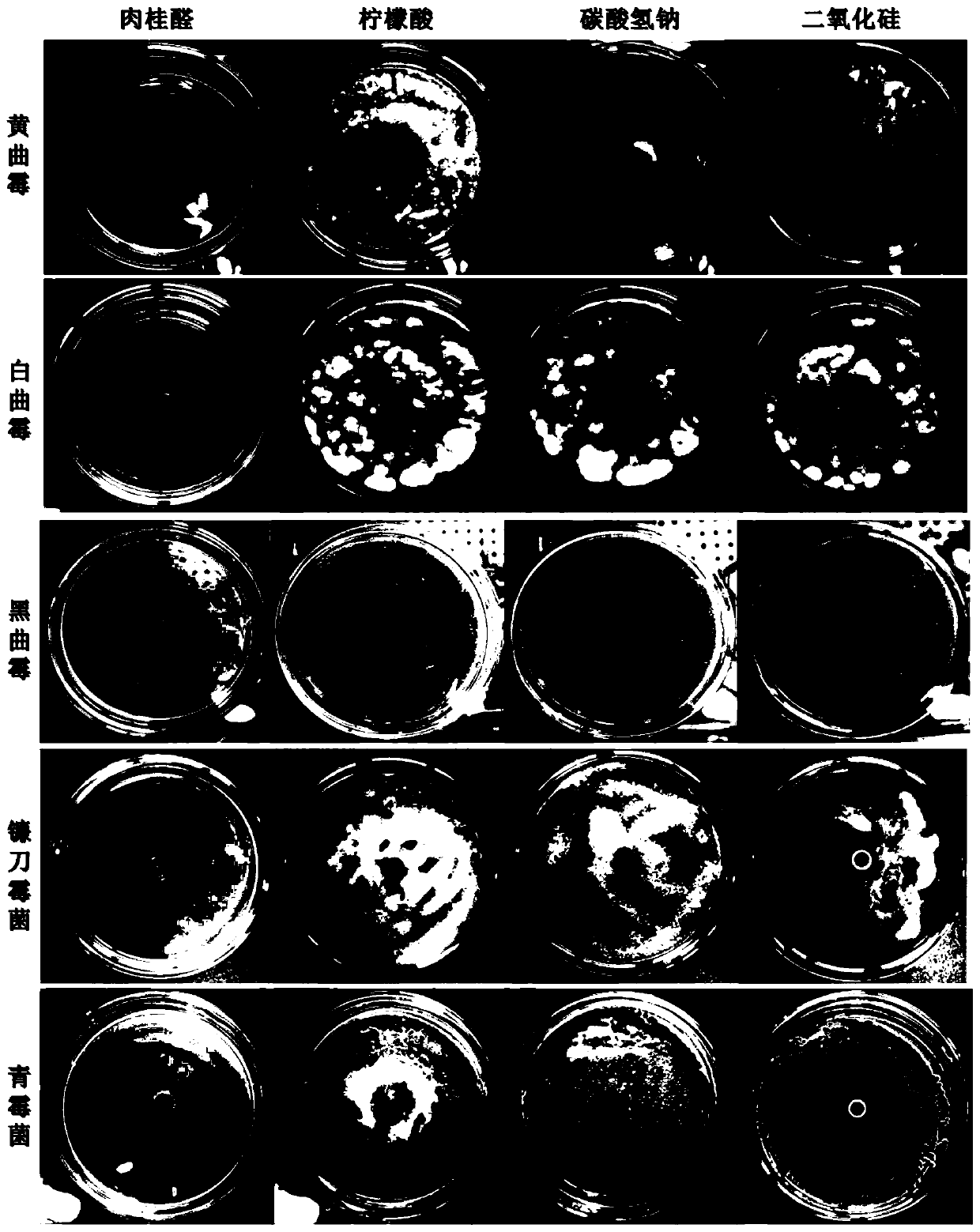

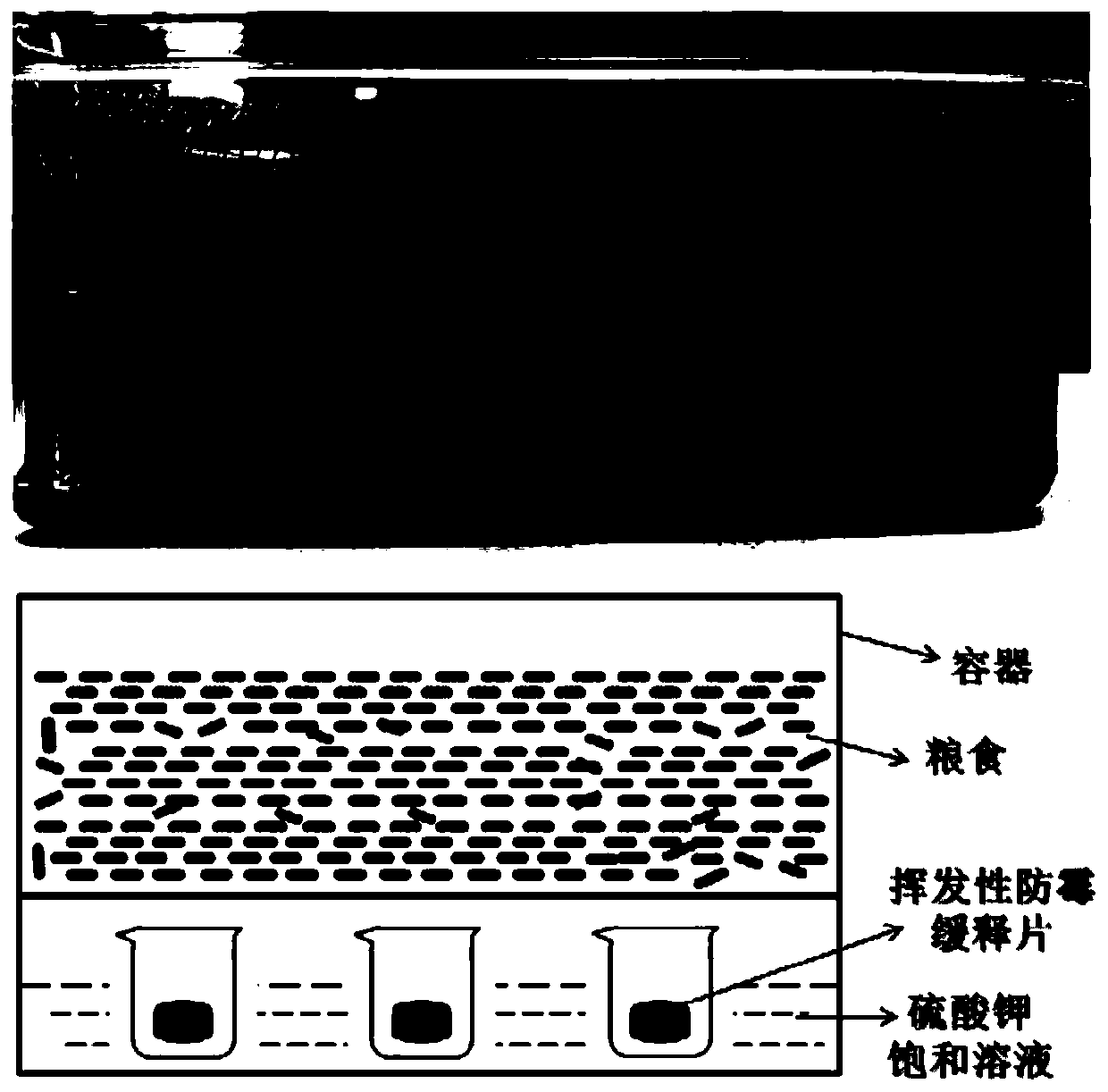

Embodiment 1

[0033] A volatile grain anti-mildew slow-release tablet, which is composed of the following raw materials in parts by weight: 48 parts of cinnamaldehyde, 22 parts of silicon dioxide, 8 parts of citric acid and 10 parts of sodium bicarbonate. Weigh cinnamaldehyde and silicon dioxide according to the above parts by weight, mix at 500rpm for 30min, then mix with the citric acid and sodium bicarbonate at 500rpm for 30min at the above parts by weight, and finally use a tablet press under 2MPa pressure After pressing for 30 seconds, volatile grain anti-mold slow-release tablets with a weight range of 0.2 g can be obtained.

Embodiment 2

[0035] A volatile grain anti-mildew slow-release tablet, which is composed of the following raw materials in parts by weight: 40 parts of cinnamaldehyde, 20 parts of silicon dioxide, 6 parts of citric acid and 8 parts of sodium bicarbonate. Weigh cinnamaldehyde and silicon dioxide by the above parts by weight, mix at 3000rpm for 5min, then mix with the citric acid and sodium bicarbonate at 3000rpm for 5min with the above parts by weight, and finally use a tablet press under 20MPa pressure After pressing for 5 seconds, a volatile grain anti-mold slow-release tablet with a weight range of 2.0 g can be obtained.

Embodiment 3

[0037] A volatile grain anti-mildew slow-release tablet, which is composed of the following raw materials in parts by weight: 50 parts of cinnamaldehyde, 25 parts of silicon dioxide, 10 parts of citric acid and 12 parts of sodium bicarbonate. Weigh cinnamaldehyde and silicon dioxide according to the above parts by weight, mix at 1000rpm for 15min, then mix with the citric acid and sodium bicarbonate at 1000rpm for 15min at the above parts by weight, and finally use a tablet press under 10MPa pressure After pressing for 15 seconds, a volatile grain anti-mold slow-release tablet with a weight range of 1.0 g can be obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com