Sanitary absorption product

A hygienic absorption and product technology, applied in medical science, bandages, etc., can solve the problems of poor diffusion, body fluid leakage, and low utilization rate of absorbent products, achieve small residual area, prevent side leakage or rear leakage, and balance the area. The effect of utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

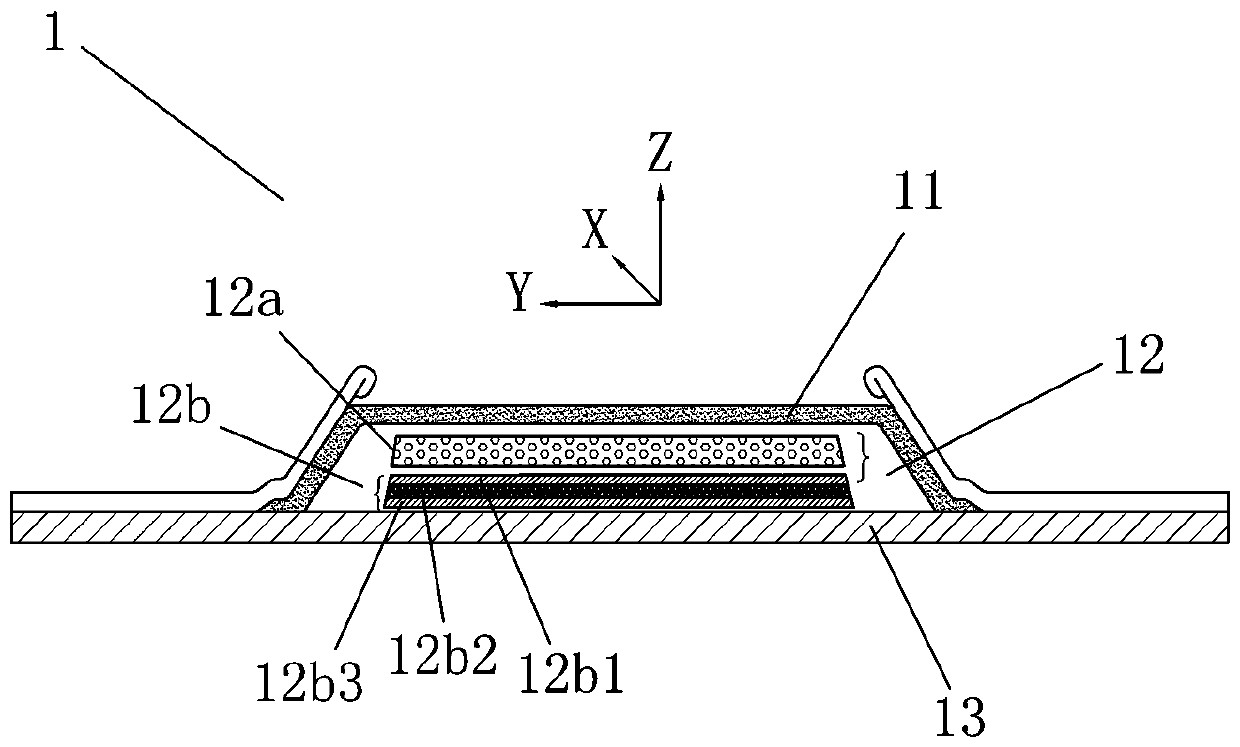

Embodiment 1

[0024] Such as figure 1 As shown, the present invention discloses a hygienic absorbent product 1, comprising a surface layer 11, an absorbent layer 12 and a breathable bottom layer 13 arranged in sequence from top to bottom, the absorbent layer 12 includes a thickness direction permeable absorbent layer 12a and a plane longitudinal / Transverse diffusion absorption layer 12b, the thickness direction penetration absorption layer 12a is composed of open-cell flexible polyurethane foam material and is located on the plane longitudinal / transverse diffusion absorption layer 12b, wherein: the opening ratio of the foam material is 80% , the compressive deformation rate of the foaming material under 0.3 PSI pressure is 20%; the planar longitudinal / transverse diffusion absorbing layer 12b comprises composite absorbent paper, and the composite absorbent paper is arranged adjacent to the thickness direction permeable absorbent layer 12a, The composite absorbent paper comprises fibrous web...

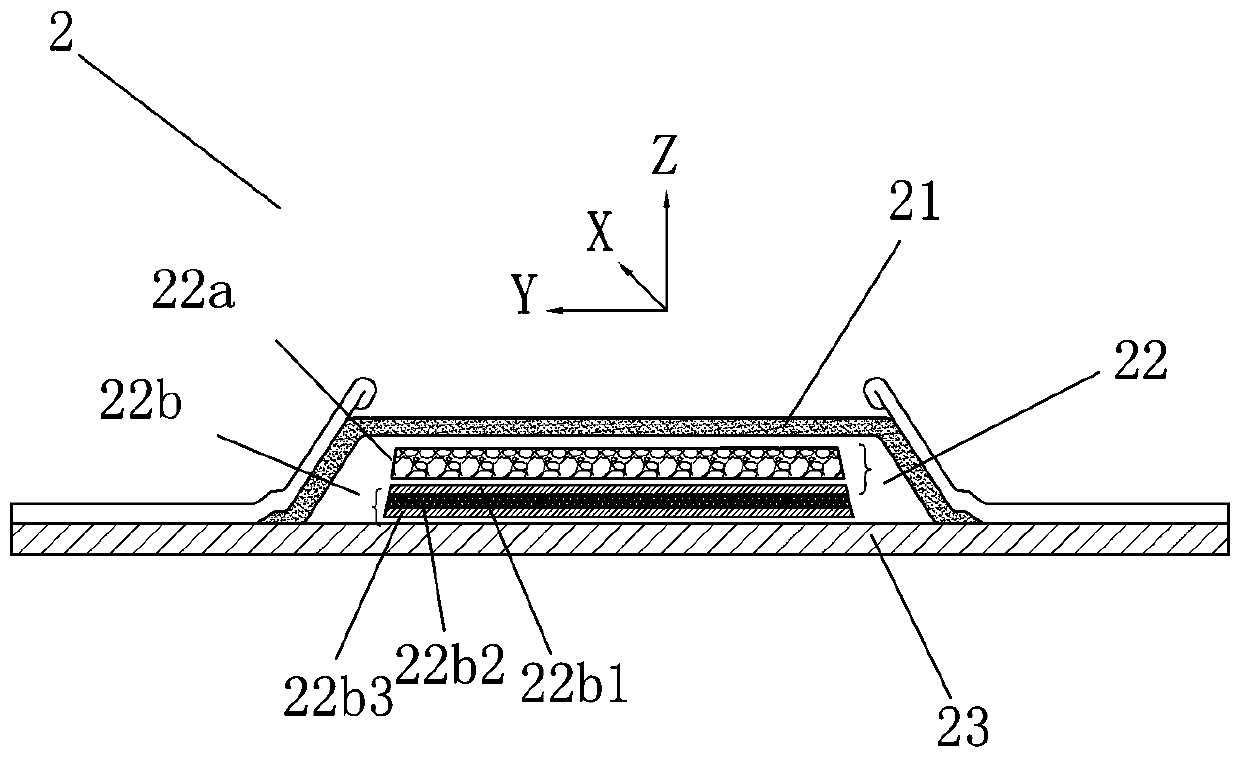

Embodiment 2

[0061] Such as figure 2 As shown, the present invention discloses a hygienic absorbent product 2, comprising a surface layer 21, an absorbent layer 22 and a breathable bottom layer 23 arranged in sequence from top to bottom, the absorbent layer 22 includes a thickness direction permeable absorbent layer 22a and a plane longitudinal / The horizontal diffusion absorption layer 22b, the thickness direction penetration absorption layer 22a, is composed of a melamine foam material with a three-dimensional three-dimensional grid opening structure and is located on the plane longitudinal / transverse diffusion absorption layer 22b, wherein: the foam material The porosity of the foamed material is 90%, and the compressive deformation rate of the foamed material is 10% under the pressure of 0.3PSI; the planar longitudinal / transverse diffusion absorbing layer 22b includes composite absorbent paper, and the composite absorbent paper is infiltrated with the thickness direction The absorbent...

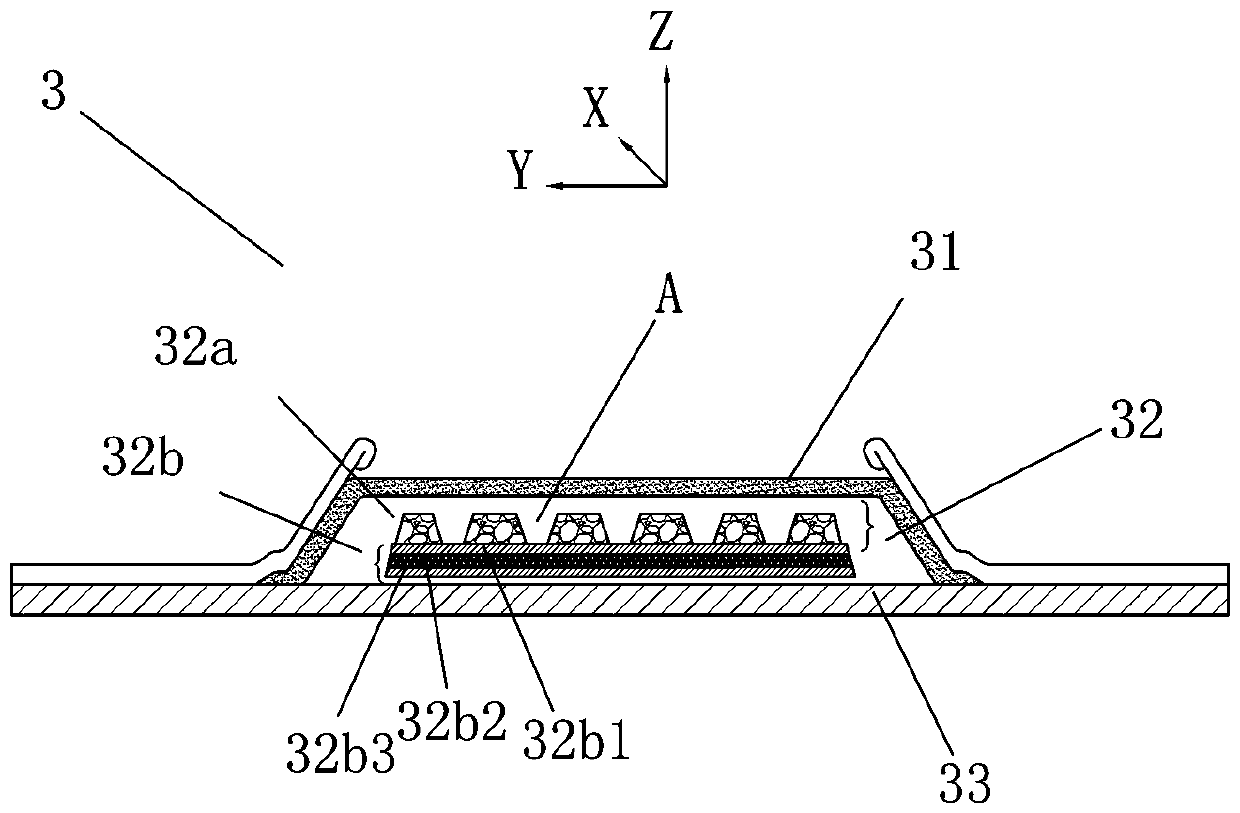

Embodiment 3

[0066] Such as image 3 As shown, the present invention discloses a hygienic absorbent product 3, comprising a surface layer 31, an absorbent layer 32 and a breathable bottom layer 33 arranged in sequence from top to bottom, the absorbent layer 32 includes a thickness direction permeable absorbent layer 32a and a plane longitudinal / Transverse diffusion absorption layer 32b, the thickness direction permeation absorption layer 32a is composed of melamine foam material with a three-dimensional grid opening structure and is located on the plane longitudinal / transverse diffusion absorption layer 32b, wherein: the foam material The porosity is 95%, the compressive deformation rate of the foamed material is 6% under the pressure of 0.3PSI, and the foamed material has a funnel-shaped opening A that runs through the foamed material; the plane longitudinal / transverse diffusion absorbs The layer 32b comprises composite absorbent paper, which is arranged adjacent to the thickness directi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com