Micro-fluidic chip for chemiluminescence detection, and using method and reagent cleaning method thereof

A chemiluminescence detection, microfluidic chip technology, applied in chemical instruments and methods, chemiluminescence/bioluminescence, biological testing, etc., can solve the problem of increasing the cost and processing difficulty of the chip manufacturing process, and inconvenient for equipment-side integration and miniaturization , unfavorable mass industrial production and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

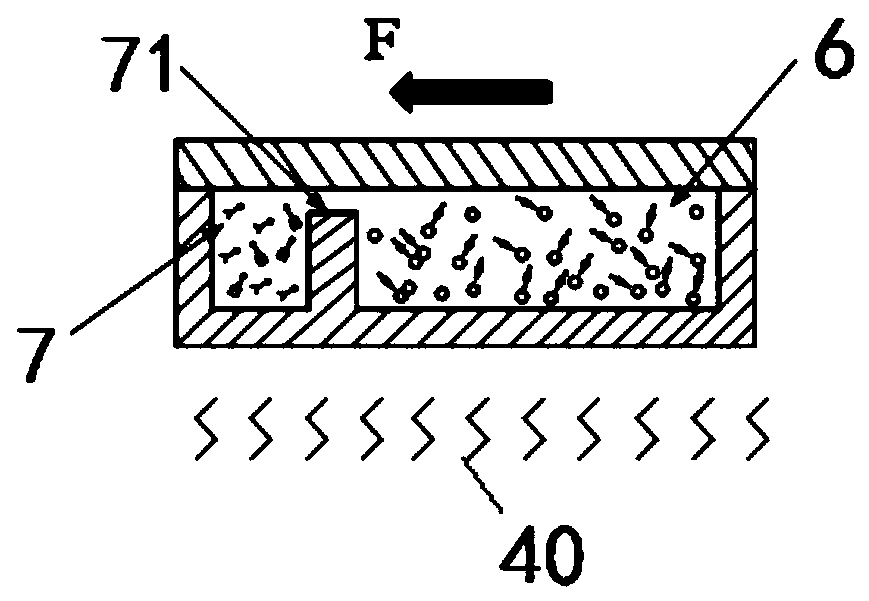

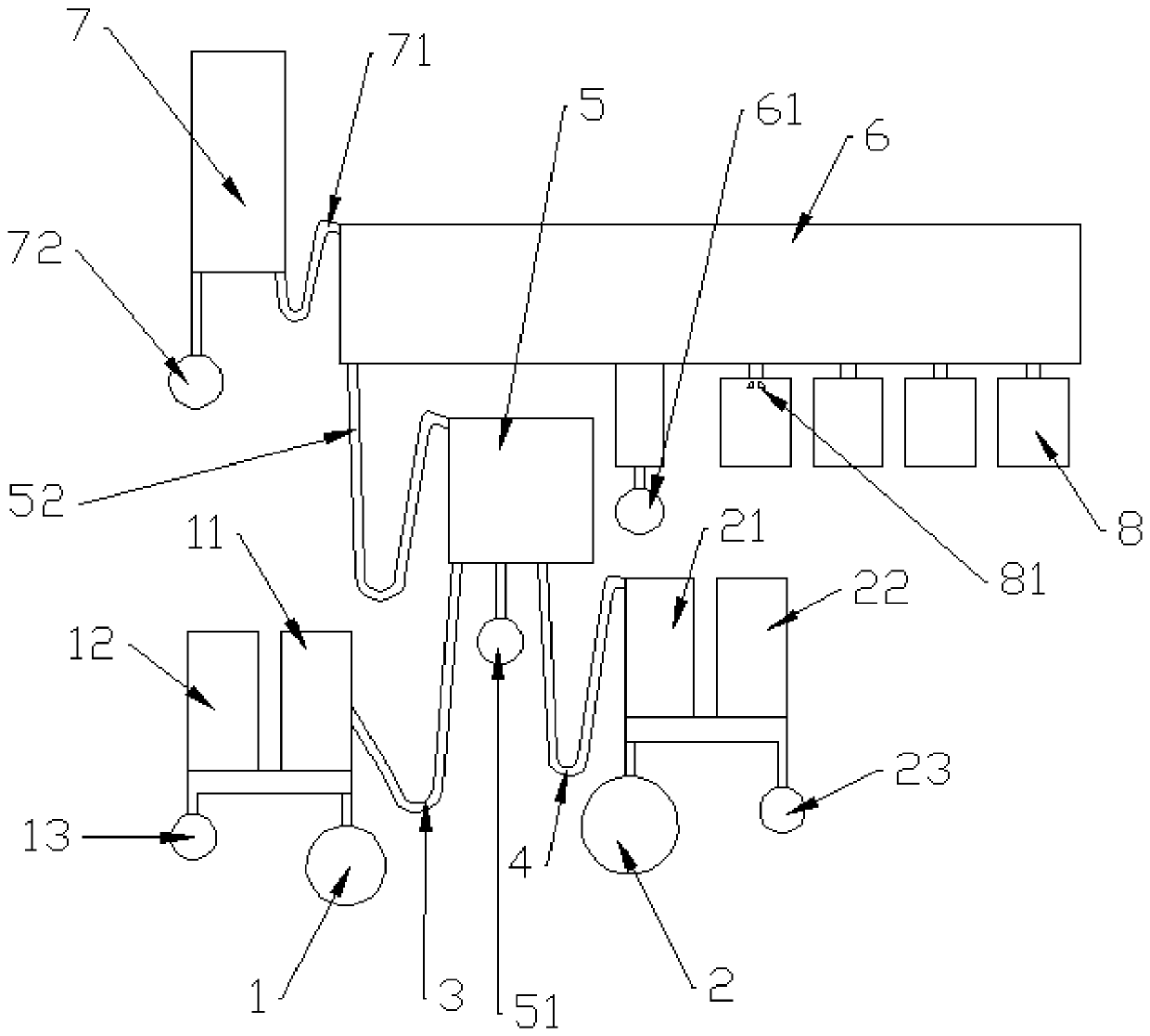

[0105] Embodiment 1: as Figure 2 to Figure 6 As shown, the number of liquid storage tanks 8 is multiple, and the lower end of the liquid storage tank 8 is provided with a piercing protrusion 81 that punctures the prepackaged water box 30 near the end of the detection tank 6, and the piercing protrusion 81 is located at Directly below the communication port between the liquid storage tank 8 and the detection tank 6, the packaging film side of the pre-packaged water box 30 is set towards the piercing protrusion 81. The internal structure of each liquid storage tank 8 is the same, and the pre-packaged water box 30 is used to realize cleaning. Liquid storage and release.

Embodiment 2

[0106] Embodiment 2: as Figure 21 As shown, the number of liquid storage tanks 8 is multiple and connected. The liquid storage tank 8 on the side away from the incubation tank 5 communicates with the diluent overflow tank 22 through the first multiple capillary flow channel 9. The first multiple capillary The flow channel 9 is provided with a first cut-off valve 91, the liquid storage tank 8 on the side away from the incubation tank 5 communicates with the detection tank 6 through the fourth capillary flow channel, and the liquid storage tank 8 on the side close to the incubation tank 5 passes through the second multi-capillary flow channel. The heavy capillary channel 84 communicates with the detection groove 6, and the second multiple capillary channel 84 is provided with a second stop valve, and the distance between the second multiple capillary channel 84 and the center of the substrate 10 is smaller than that of the first multiple capillary channel 9 Distance from the ce...

Embodiment 2

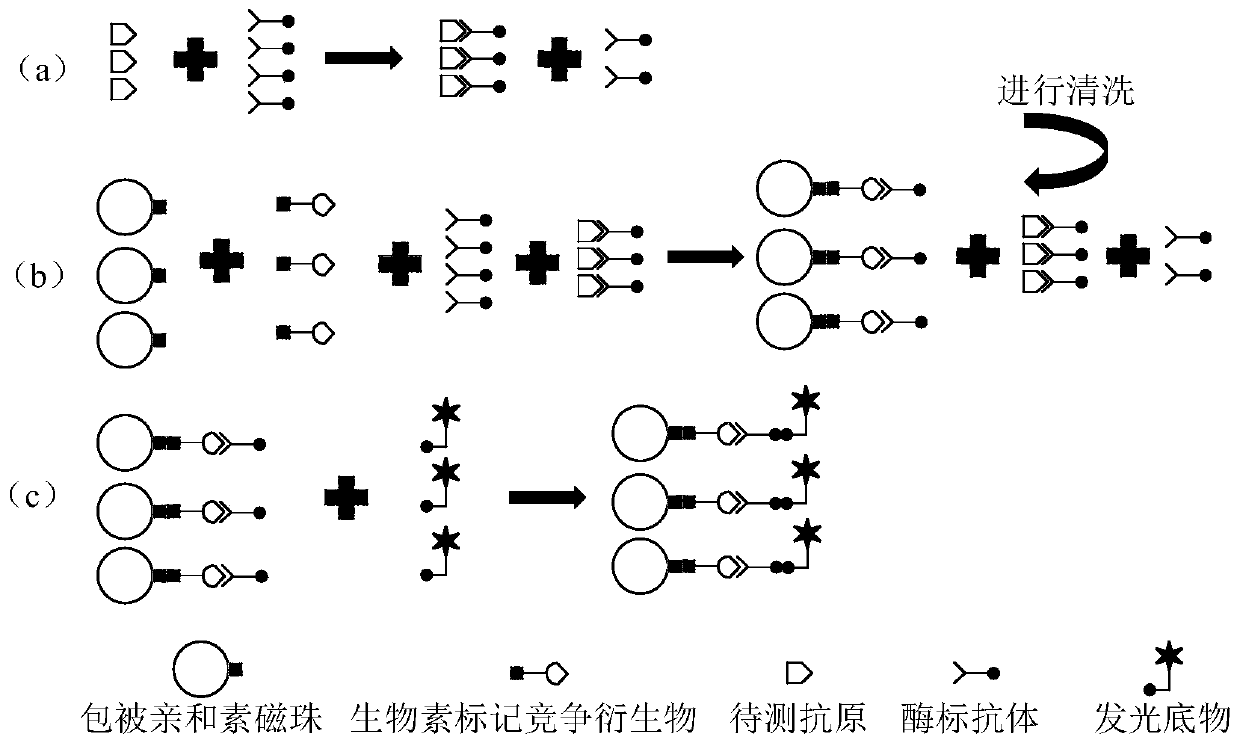

[0128] For example 2: if Figure 21 ~ Figure 33 As shown, in the actual practical process, the enzyme-labeled antibody freeze-dried reagent pellets are pre-packaged in the incubation tank 5, the luminescent substrate reagent freeze-dried pellets are pre-packaged in the cleaning solution quantitative tank on the far right, and the biotin-labeled The competition derivative freeze-dried reagent pellets and the freeze-dried reagent pellets coated with avidin magnetic beads are prepackaged in the detection groove 6 .

[0129] S1: Put a sufficient amount of sample to be tested in the sample adding tank, the sample can be blood sample, urine, sweat, etc., add a sufficient amount of purified water in the diluent sample adding tank, the purified water needs to be purified, specific Sterilization is also required during the test;

[0130] S2: Place the microfluidic chip on the centrifugal platform and fix it, and the motor starts to rotate. Under the action of centrifugal force, the sa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com